U-shaped toughened float/rolled/figured glass and manufacturing method thereof

A technology of float glass and glass, which is applied in the direction of building components, buildings, building structures, etc. It can solve the problems of large damage, poor impact resistance, and poor recycling, and achieve soft light, good thermal stability, and impact resistance. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

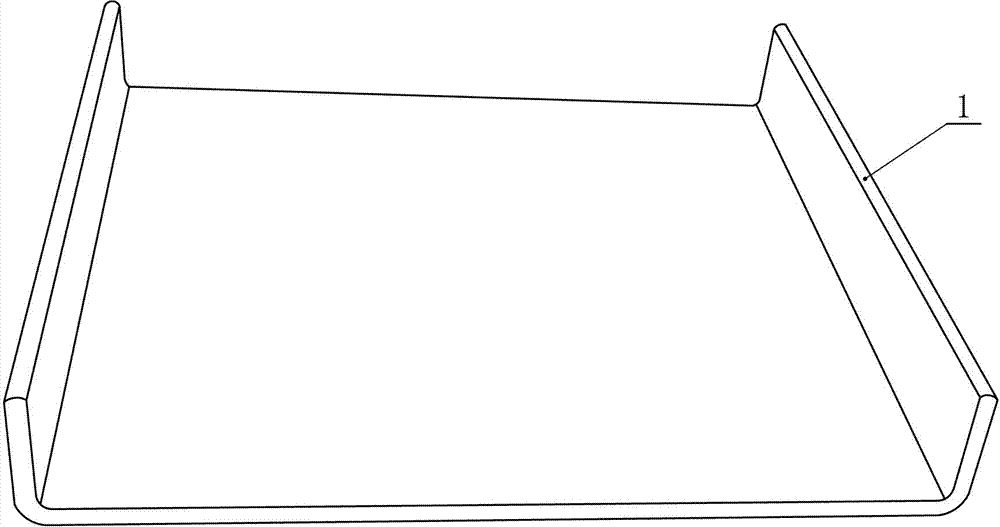

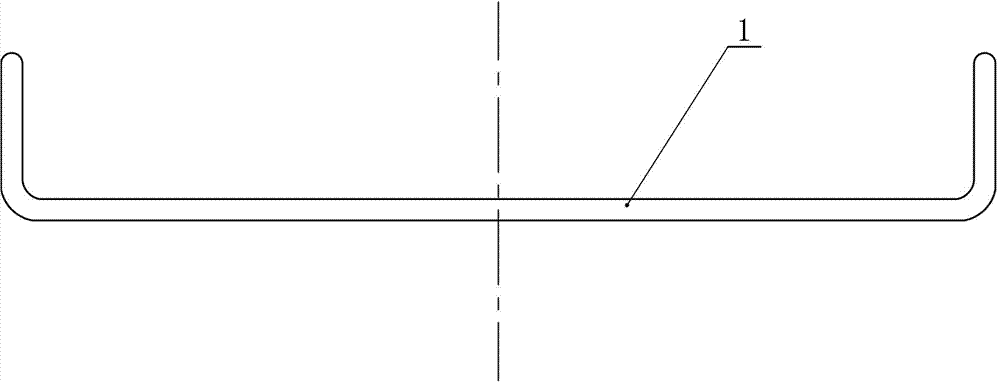

[0030] The invention utilizes ordinary flat float glass or common flat calendered (embossed) glass to form U-shaped toughened float glass or calendered (embossed) glass through a deformation and tempering process. Ordinary flat float glass or ordinary flat calendered (embossed) glass that can be tempered offline or online is sent to a deformable tempering furnace for heating after cutting, edging, and cleaning, and is formed after deformation, air cooling, and quenching. U-shaped tempered float glass or rolled (patterned) glass.

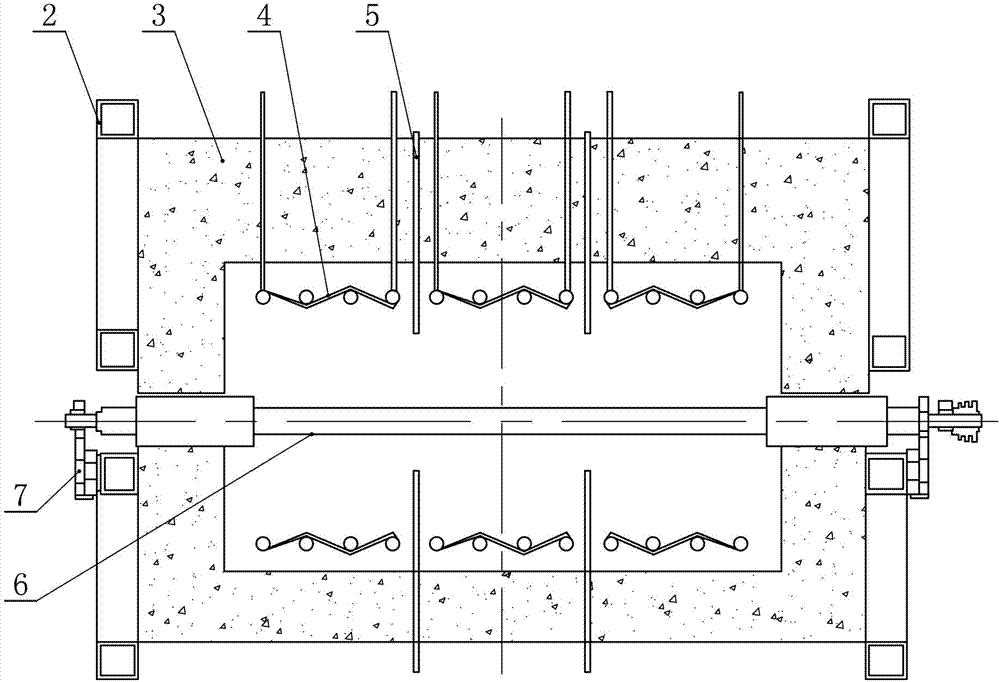

[0031] The present invention also can adopt following device to implement the present invention except that existing known technology can be adopted to implement the present invention:

[0032] The device is a flat glass forming and U-shaped glass tempering device, which includes a forming roller mechanism in a furnace and a shape correcting device.

[0033] The device is a forming roller table mechanism in a U-shaped tempered glass furnace, which i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap