Sensor device

A technology for sensor devices and sensor housings, applied to measuring devices, instruments, devices using electric/magnetic methods, etc., can solve problems such as the influence of reading accuracy, signal distortion, and the difficulty of accurately estimating angular position and rotational speed. Achieve the effect of simple signal valuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

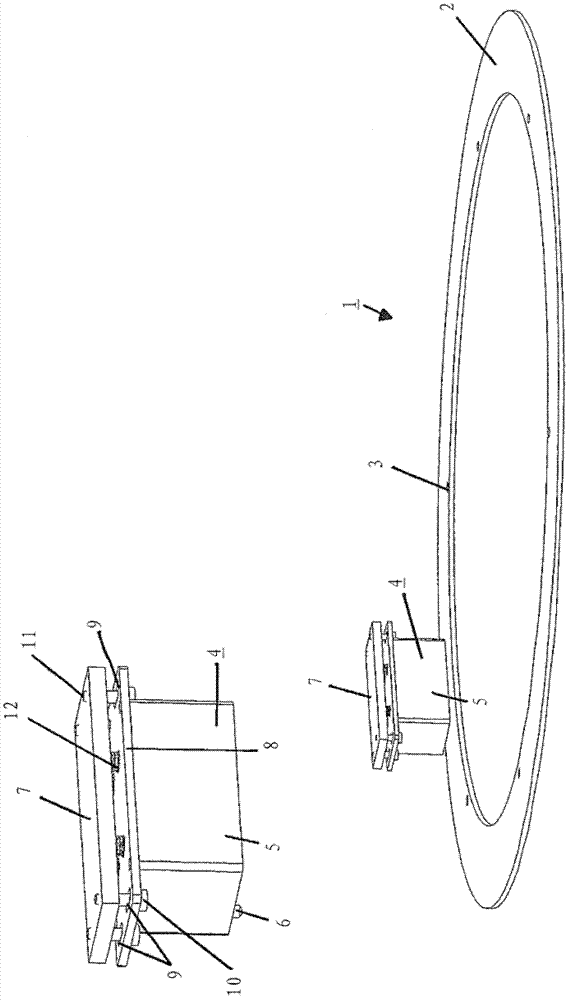

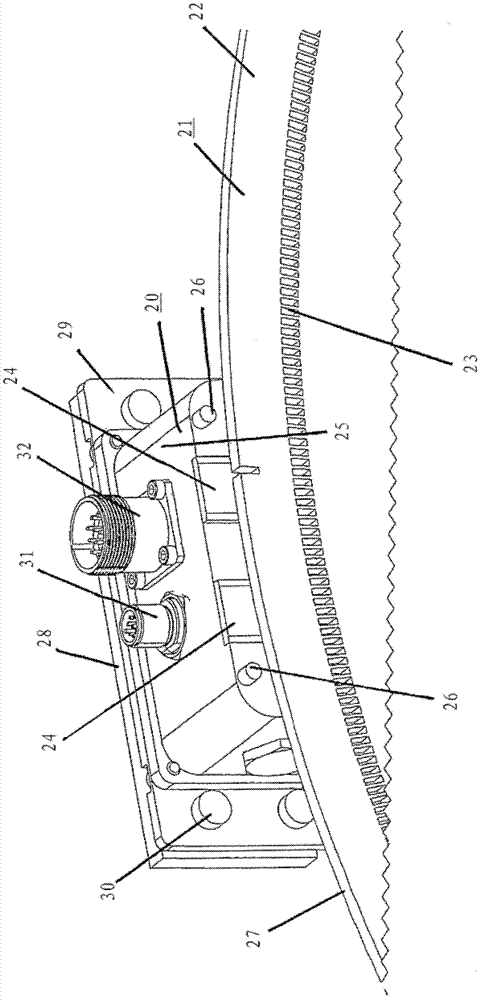

[0026] figure 1A first possible embodiment for a calibration body with a sensor device is shown in a perspective view. In this case, an annular element 2 is provided as calibration body 1 , which can be screwed, for example, on the end side by means of a bore 3 in the shaft. The shaft itself is not shown. The marking body provided on the ring element 2 is also not shown, wherein the marking body can be formed, for example, from one coding track or possibly also from up to three coding tracks. In this case, the individual coding tracks are arranged on different diameters, wherein at the same time it is ensured by the sensor device 4 that all coding tracks can be scanned by means of the sensor elements.

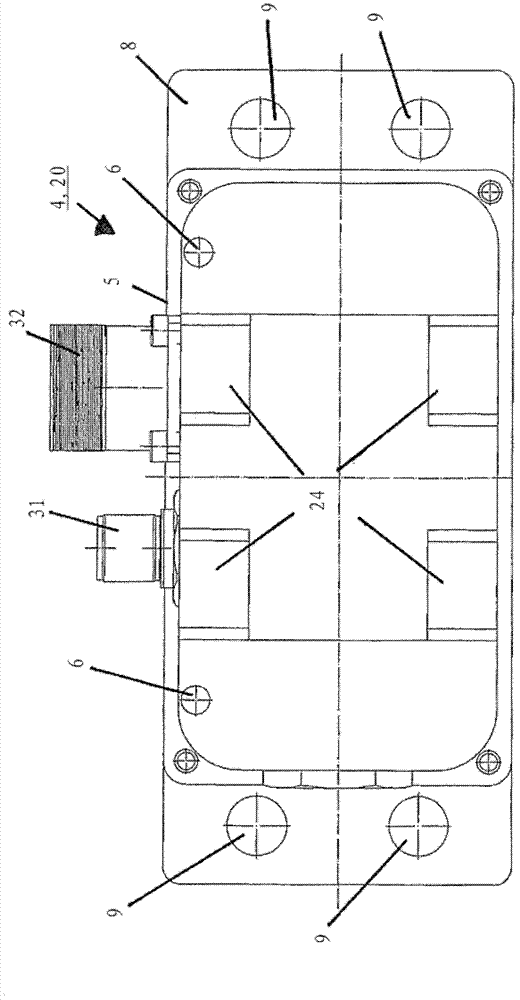

[0027] The sensor device 4 comprises a housing 5 which is held directly in radial contact with the ring element 2 by means of a pin 6 , while the housing 5 is additionally mounted axially floating. A mounting plate 7 is provided for this purpose, which can be fastened, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com