Non-contact hot rolled steel coil inner tower defect measuring method

An inner-tower, non-contact technology for hot-rolled steel coils, applied in measuring devices, optical testing flaws/defects, instruments, etc. Operation risk, easy operation, safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A non-contact method for measuring the defects of the inner tower of the hot-rolled steel coil. The invention uses a measuring device to measure the length of the inner tower of the hot-rolled steel coil remotely. The specific steps are as follows:

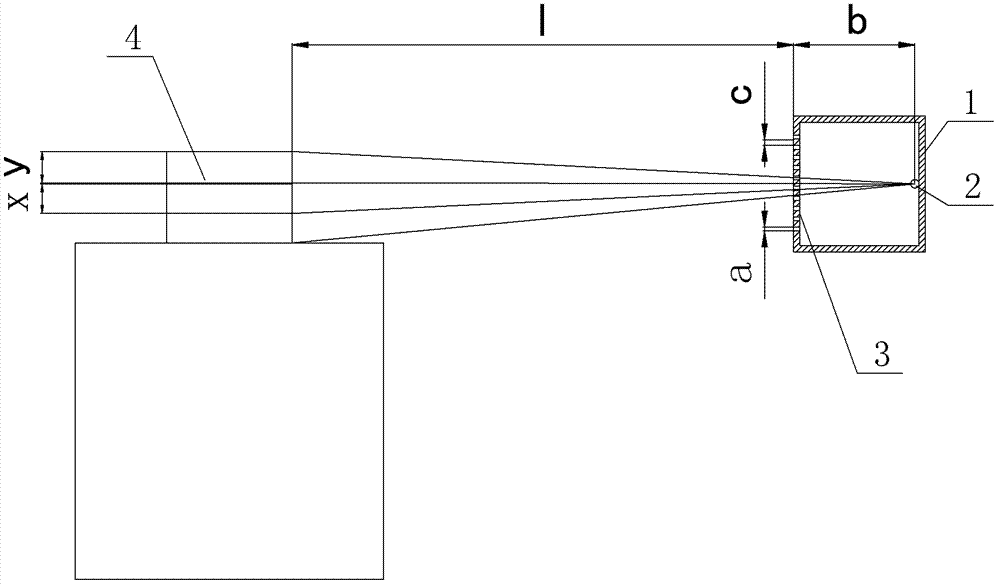

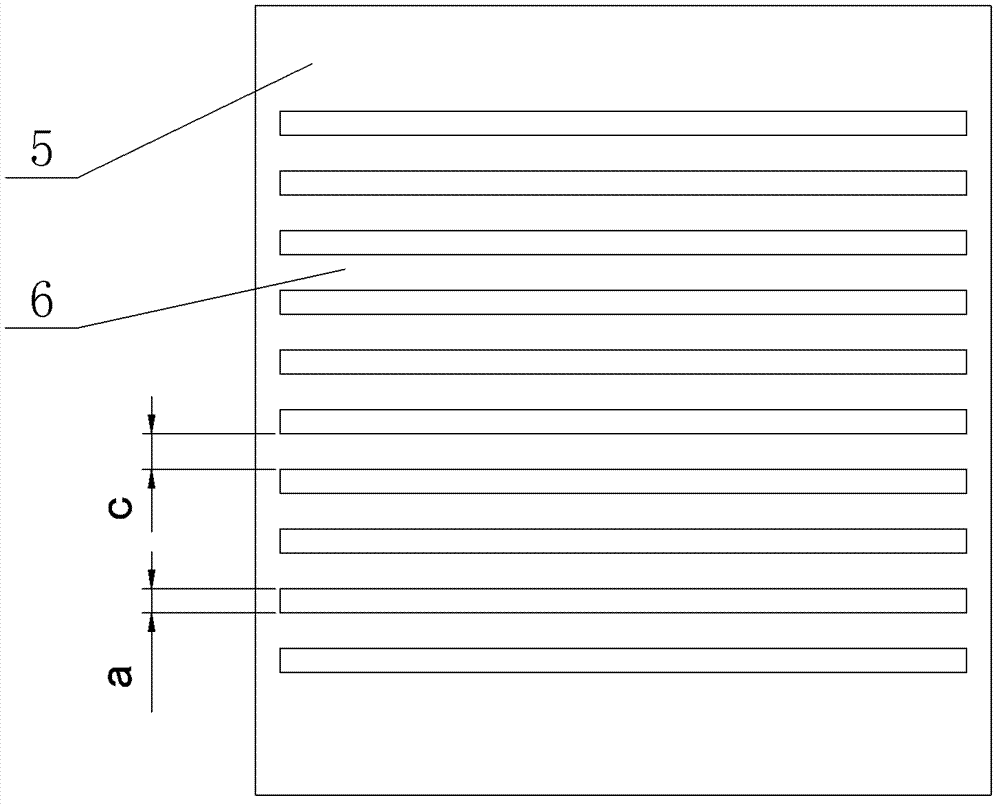

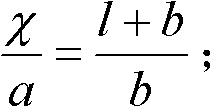

[0038] 1) if figure 1 As shown, a hollow box 1 is set at a distance of 3000 mm from the inner tower of the steel coil. The side of the box 1 facing the steel coil is a light-transmitting plate 3, and the other sides are all opaque. The side opposite to the light-transmitting plate 3 A light source 2 is provided on the inner wall of the side box body 1; figure 2 As shown, the light-transmitting plate 3 adopts a window-sill structure design, the light-transmitting plate 3 includes an outer frame 5 and a light-shielding strip 6, the outer frame 5 is in a rectangular design, the light-shielding strips 6 are equidistantly arranged in parallel, and the two ends of the light-shielding strip 6 are aligned with the Two opposite si...

Embodiment 2

[0050] A non-contact method for measuring the defects of the inner tower of the hot-rolled steel coil. The invention uses a measuring device to measure the length of the inner tower of the hot-rolled steel coil remotely. The specific steps are as follows:

[0051] 1) if figure 1 As shown, a hollow box 1 is set at a position 3500mm away from the inner tower of the steel coil. The side of the box 1 facing the steel coil is a light-transmitting plate 3, and the other sides are all opaque. The side opposite to the light-transmitting plate 3 A light source 2 is provided on the inner wall of the side box body 1; figure 2 As shown, the light-transmitting panel 3 adopts a window-sill structure design, the light-transmitting panel 3 includes an outer frame 5 and a shading strip 6, the outer frame 5 is in a rectangular design, and the shading strips 6 are equidistantly arranged in parallel, and the width of the shading strip 6 is the same as The distances between two adjacent shading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com