Copper core dividing conductor with large cross section

A technique for dividing conductors and large cross-sections, which is applied in the direction of conductors, insulated conductors, and non-insulated conductors. It can solve the problems of large power loss and low current carrying capacity, and achieve the effects of difficult processing, reduced AC resistance, and firm conductors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

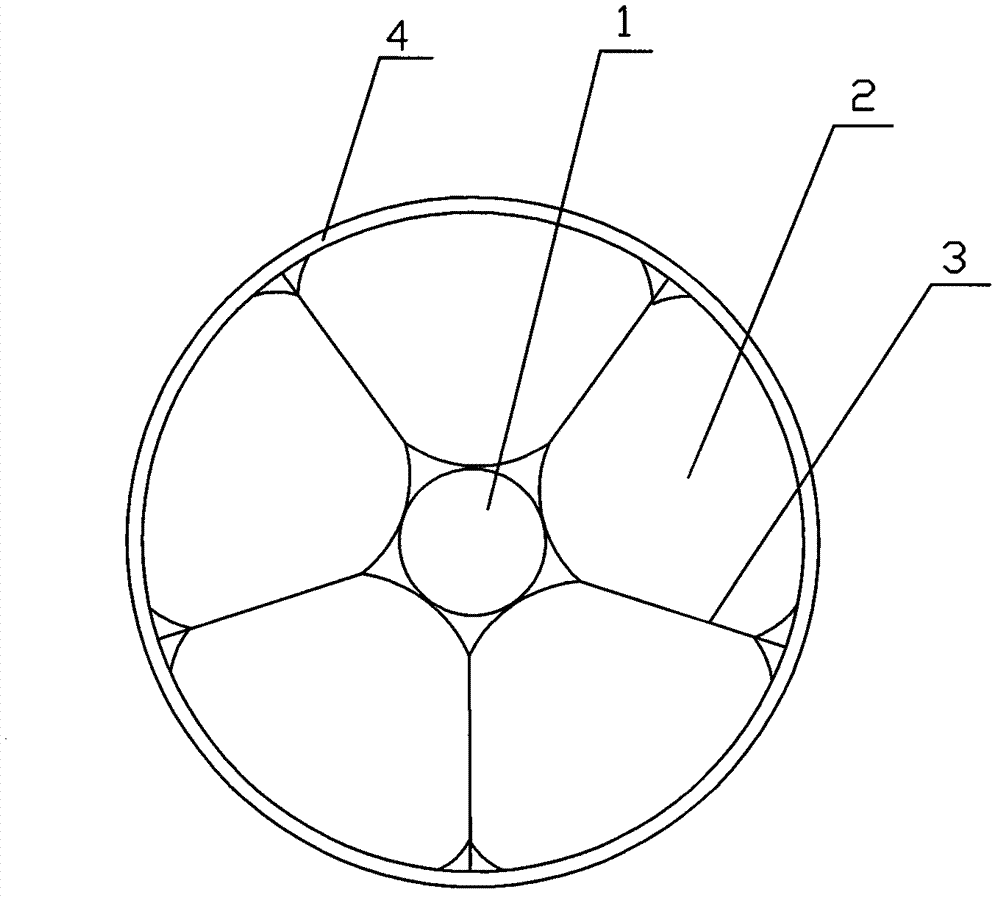

[0009] A large cross-section copper core split conductor, including a central unit stranded conductor 1 and five fan-shaped copper core strands 2 with the same size and cross-sectional shape, the central unit stranded conductor 1 is 50mm 2 , the outer diameter is controlled at 8.0-8.03mm, and the DC resistance at 20°C is not greater than 0.387Ω / km. The five fan-shaped copper core strands 2 are wound around the circumference of the central unit stranded conductor 1 in turn, and the five Among the four fan-shaped copper core strands 2, only one fan-shaped copper core strand 2 is in direct contact with the central unit stranded conductor 1, and an insulating tape is provided between the remaining four fan-shaped copper core strands 2 and the central unit stranded conductor 1 3. An insulating tape is provided between the five fan-shaped copper core strands, and the central unit stranded conductor 1 and the five fan-shaped copper core strands 2 are wrapped with a semi-conductive tef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com