Separating conductor for ultra-high voltage cable

A split conductor, ultra-high voltage technology, applied in the direction of conductors, insulated cables, power cables, etc., can solve the problems of lack of longitudinal water resistance and "big skin effect"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with exemplary embodiments and accompanying drawings, but the examples should not be construed as a specific limitation to the present invention.

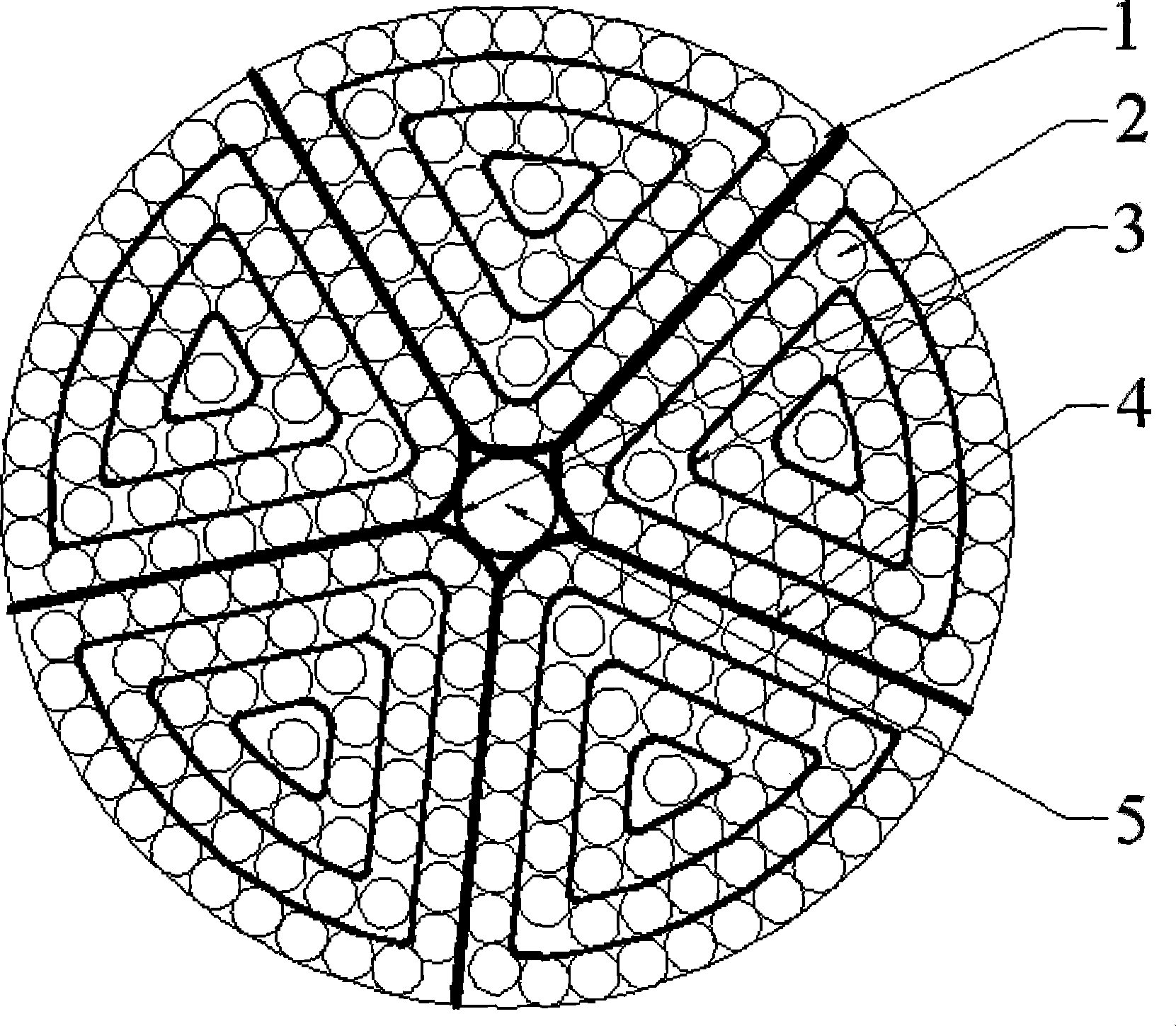

[0011] see figure 1 , a split conductor of an extra-high voltage cable, comprising several split strands 1 and a single round wire 5, several round single wires 2 twisted into split strands 1, and the central gap after the combination of several split strands 1 is disposed of A single round wire 5 is coated with an insulating water-blocking paste 3 outside the single round wire 5, and the divided strands 1 are separated from the divided strands 1 by an insulating water-blocking tape 4. Each of the divided strands 1 Insulating water-blocking paste 3 is also coated between layers of circular single wires 2 .

[0012] see figure 1 , the split stock block 1 is five shares.

[0013] see figure 1 , the split strand 1 includes several layers of fan-shaped twis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com