Robot system

A robot system, a technology of a robot hand, applied in the field of robot systems, can solve problems such as inability to effectively unload wafers, not always able to effectively unload storage box wafers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A robot system according to an embodiment of the present invention will be described below with reference to the accompanying drawings. The present invention is not limited to the embodiments described below.

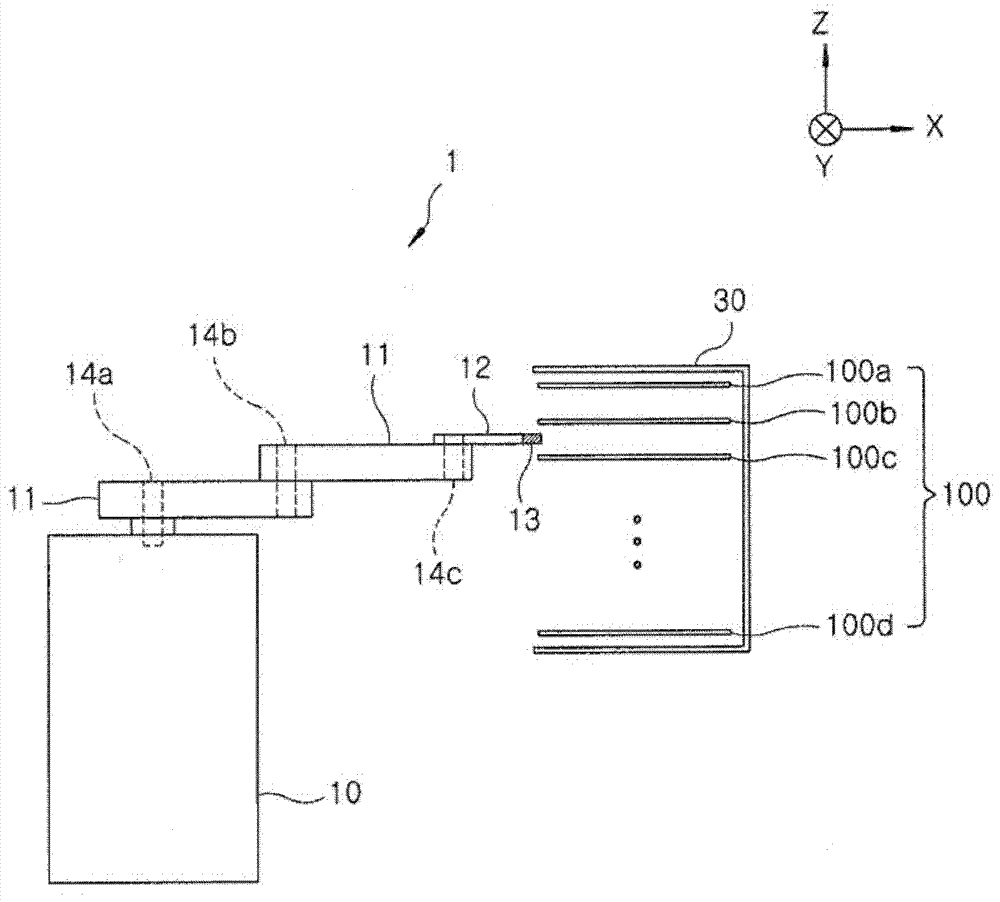

[0023] First, refer to figure 1 The robot system 1 according to the embodiment will be described. figure 1 is an explanatory diagram of the robot system 1 according to the first embodiment. To simplify the description, figure 1 The shapes of some components are schematically shown.

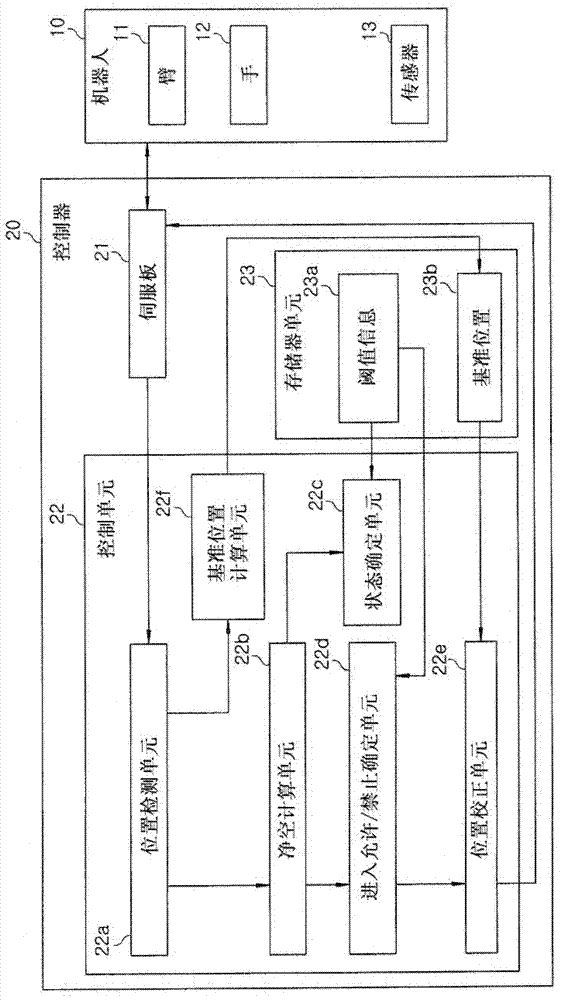

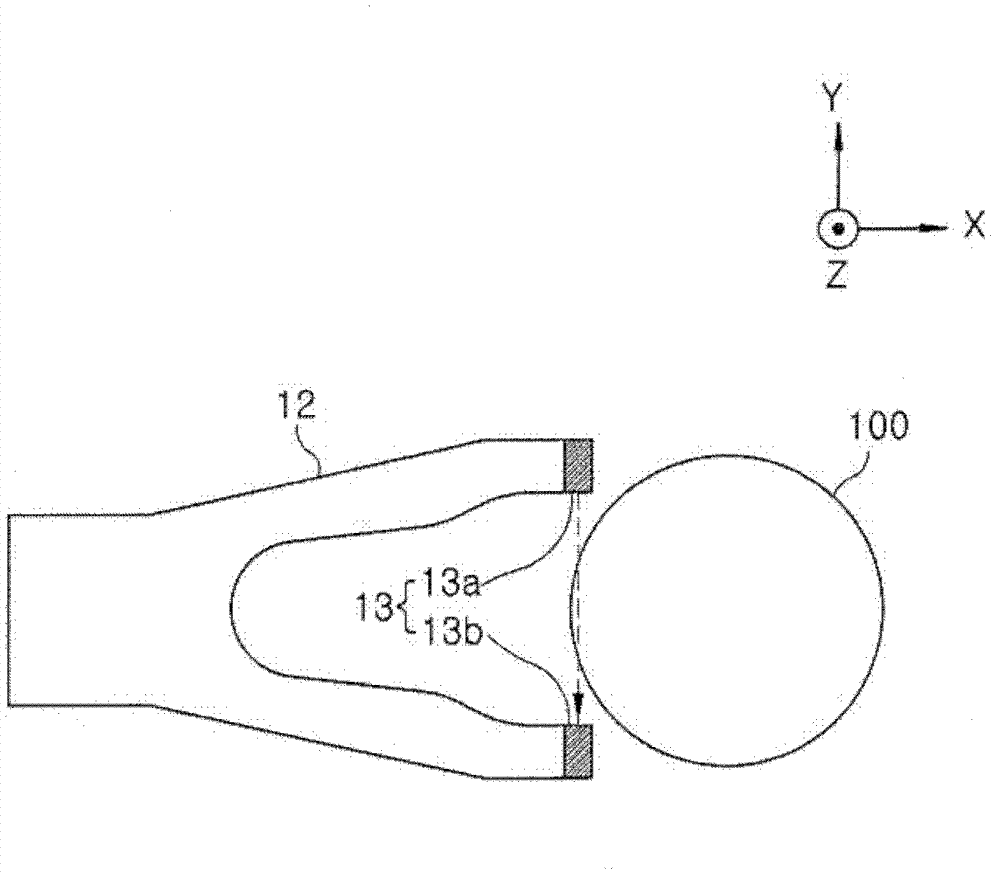

[0024] refer to figure 1 , the robot system 1 according to this embodiment includes a robot 10 and a controller 20 (see figure 2 ). The robot 10 includes an arm unit formed of a plurality of arms 11 . A hand 12 is provided at the tip portion of the arm 11 farthest from the robot 10 . A sensor 13 is provided at the tip portion of the hand 12 .

[0025] Each arm 11 is connected to the other arm 11 or hand 12 by joints 14a, 14b and 14c. Joints 14a, 14b and 14c, for example, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com