Three-phase asynchronous motor energy-saving device

A motor energy-saving, three-phase asynchronous technology, applied in the direction of AC motor control, electrical components, control systems, etc., can solve the problems of power waste, motor efficiency reduction, low power factor, etc., and achieve low production cost, reasonable setting, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

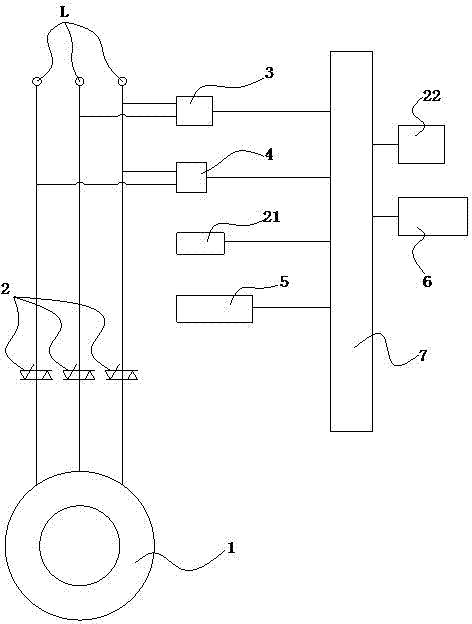

[0014] Such as figure 1 As shown, a three-phase asynchronous motor energy-saving device according to the present invention includes a motor 1, the wiring ports of the motor 1 are respectively connected to the three-phase power supply L, and the wiring ports of the three-phase power supply L and the motor 1 A thyristor 2 is arranged between them, and any two power lines of the three-phase power supply L between the thyristor 2 and the three-phase power supply L are respectively connected with a power supply circuit 3 and a phase sequence detection 4, and the power supply The terminal of the circuit 3 is connected to the power port of the single-chip microcomputer 7, the corresponding terminal of the phase sequence detection 4 is fixedly connected to the corresponding pin of the single-chip microcomputer 7, and the working signal interface 21 and the trigger interface 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com