Sector-shaped spraying generating device

A technology of generating device and fan shape, applied in the direction of spraying device, spraying device, etc., can solve the problems of small cleaning force, no water saving effect, and inability to form a suction effect, etc., to achieve strong spraying force, good water saving effect, particle delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

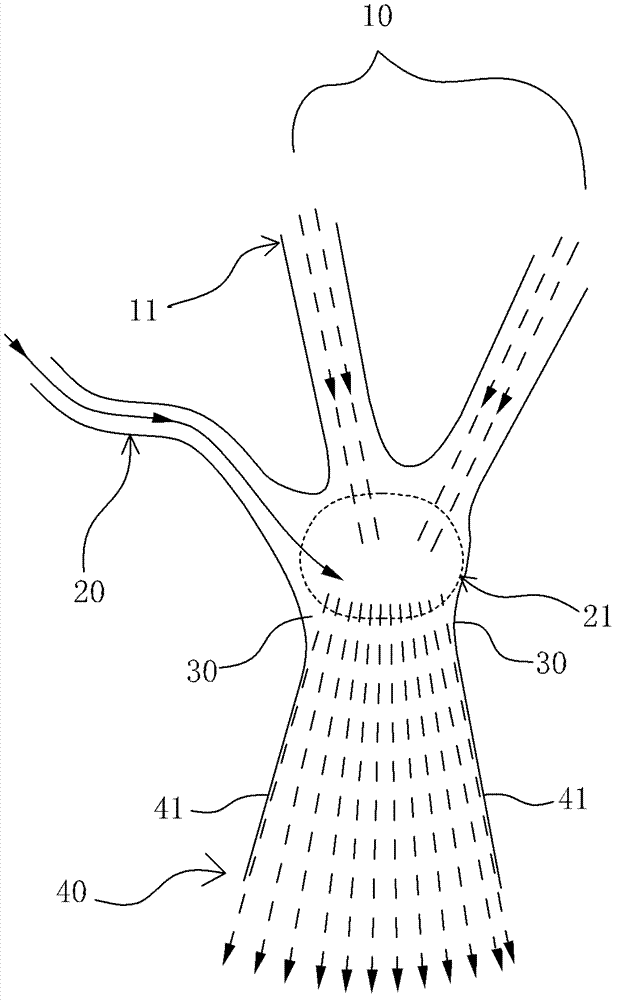

[0028] Such as figure 1 Shown is a schematic diagram of an embodiment of the invention with liquid and air flow. There are two water inlet passages 11, which have obvious angles between each other. The two water inlet passages 11 converge in the intersection area 21 shown by the closed dotted line; the intersection area 21 is also connected to an air suction channel 20, and the air suction channel 20 The inlet is exposed to the air in free space and has a pressure of one atmosphere.

[0029] The dotted arrows indicate the direction of water flow, and the solid arrows indicate the direction of air flow.

[0030] Downstream of the converging area 21 is a flat spout 40 , the flat spout 40 has a substantially uniform thickness in the direction perpendicular to the paper, and is much smaller than the distance between the shaping walls 41 , and is flat. The flat nozzle 40 has a throat 30 near the confluence region 21 . The cross-sectional area where the throat 30 is located is sl...

Embodiment 2

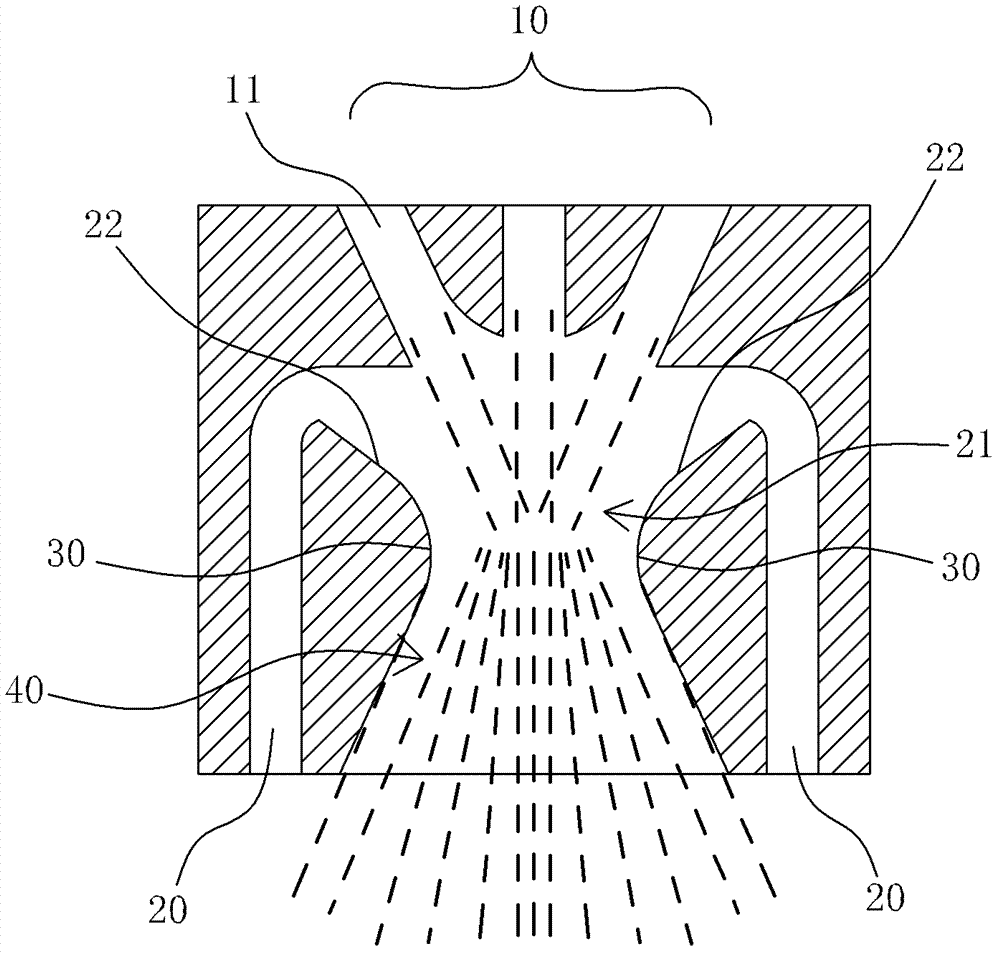

[0033] Such as figure 2 Shown is a schematic diagram of Embodiment 2 of the present invention. In this embodiment, the water inlet 10 , the suction channel 20 , the throat 30 , and the flat nozzle 40 are all left-right symmetrical, and have the same depth in the direction perpendicular to the paper. The water inlet 10 has three water inlet channels 11 . The air suction channel 20 has an inclined surface 22 near the confluence region 21 towards the flat nozzle 40 . This inclined surface makes it difficult for the air bubbles to block the air suction channel 20 , so that it can be sprayed out from the flat nozzle 40 smoothly.

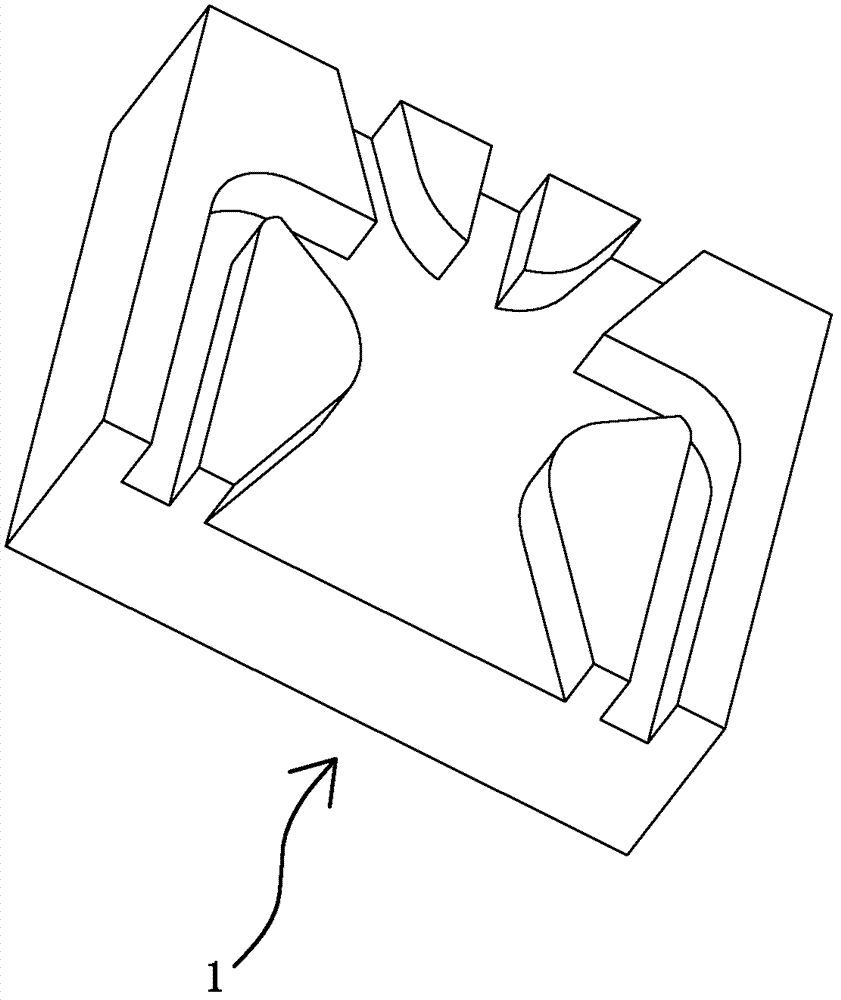

[0034] image 3 yes figure 2 Example product perspective view. All waterways are formed on a rectangular face of a mosaic 1 with the same depth. The inlay 1 is inlaid and fixed on the required equipment, thus constituting a modular accessory; combining figure 2 It can be seen that the suction channel 20 and the outlet of the flat nozzle 40 are on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com