Preparation method of epoxy resin emulsion

A technology of epoxy resin emulsion and epoxy resin, which is applied in the direction of epoxy resin coatings and coatings, can solve the problems of low strength, poor toughness and poor water resistance of water-based epoxy coatings, and achieve improved water resistance and good centrifugal stability Concentration effect of property and particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

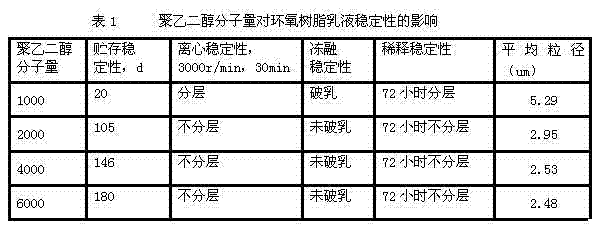

Embodiment 1

[0019] First, heat 20g of polyethylene glycol with a molecular weight of 1000, 9.2g of HDI and 0.03g of dibutyltin dilaurate to 70°C under a nitrogen atmosphere, and after stirring for 3 hours, lower the temperature to 60°C and add 1.48g Glycidyl alcohol, continue to react at 60°C for 6 hours to obtain an emulsifier. Take 60g of epoxy resin E51, 3g of propylene glycol methyl ether and 8g of the prepared emulsifier and mix them for emulsification, add 50g of water dropwise within 8min, and increase the emulsification speed from 0 r / min to 2500r / min at the same time, and maintain the speed of 2500r / min Stir at a rotating speed for 10 min to obtain an epoxy resin emulsion.

Embodiment 2

[0021] On the basis of Example 1, 20 g of polyethylene glycol with a molecular weight of 1000 was changed to 80 g of polyethylene glycol with a molecular weight of 4000, and the others remained unchanged.

Embodiment 3

[0023] On the basis of Example 1, 20 g of polyethylene glycol with a molecular weight of 1000 was changed into 120 g of polyethylene glycol with a molecular weight of 6000, and the others remained unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com