Umbrella-holding type pipeline tensioning mechanism

A tensioning mechanism and umbrella support technology, which is applied to metal processing machinery parts, clamping, support, etc., can solve the problems of high cost of tensioning tooling and waste of tensioning tooling, and achieve improved production efficiency, simple structure, and reduced vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following describes the technical solution of the present invention in detail through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

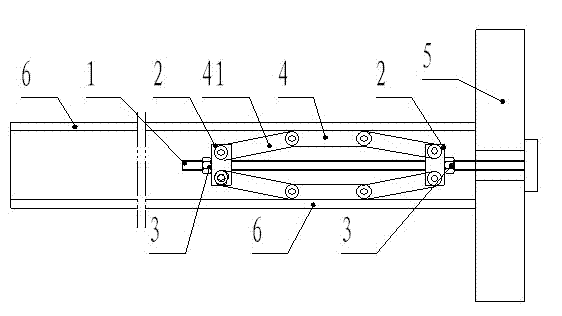

[0016] Such as figure 1 As shown, an umbrella-supported pipeline tensioning mechanism includes a central shaft 1 and two movable blocks 2 sleeved on the central shaft. The movable block 2 is provided with a locking device 3 fixed to the central shaft. At least three sets of tensioning links 4 for supporting the inner wall of the pipeline are arranged between the two movable blocks. The tensioning links 4 include three links 41 hinged to each other, and the links 41 at both ends are respectively connected to the two Two movable blocks are hinged, and the connecting rods 41 at both ends of each group of tensioning rods are equal in length, and the middle connecting rod is provided with a rubber layer for shock absorption, and the locki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com