Pneumatic floating-supporting device

A floating support and pneumatic technology, applied in positioning device, support, clamping and other directions, can solve the problems of elastic deformation, spring knife, fixed support column support height cannot be adjusted, etc., to achieve the effect of preventing deformation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

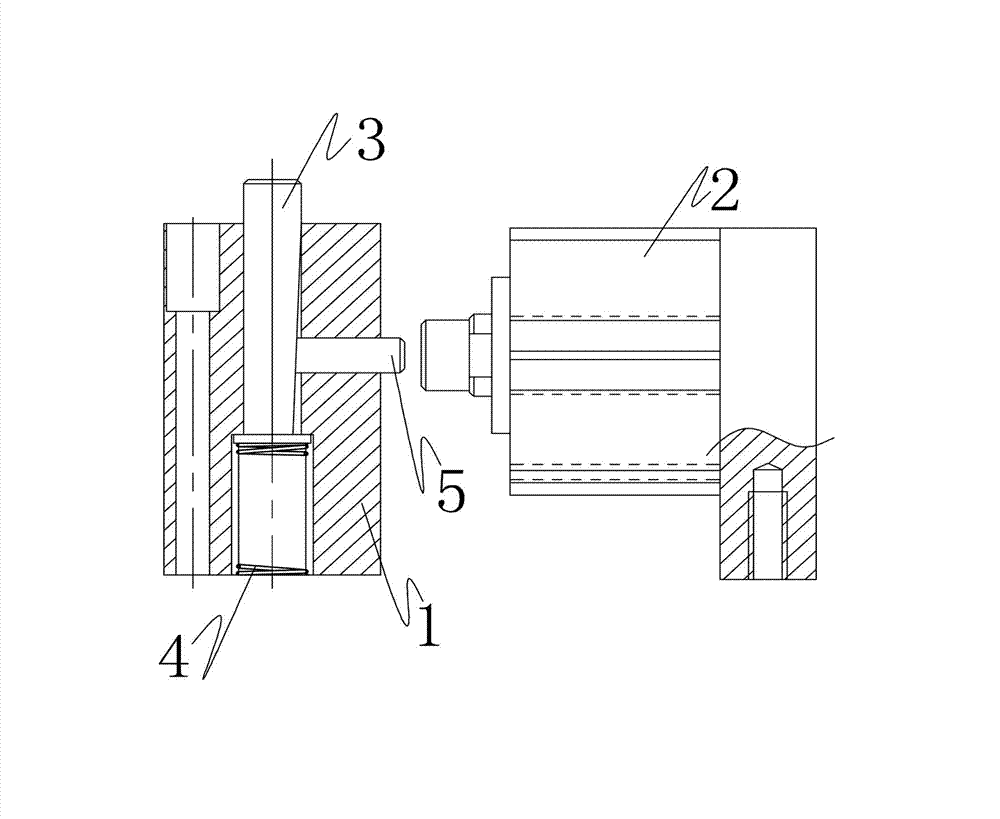

[0012] refer to figure 1 , a pneumatic floating support device, comprising a support sleeve 1 mounted on a workpiece tooling through bolts, and a locking cylinder 2 is arranged adjacent to the support sleeve 1 .

[0013] The support sleeve 1 is provided with a floating support column 3 aligned with the supporting part of the thin-walled part. The upper end of the floating support column 3 protrudes from the support sleeve 1, and the lower end of the floating support column 3 is provided with a spring 4. The floating support column 3 can be placed on the support sleeve. 1 reciprocates up and down; the side of the support sleeve 1 is provided with a pin hole, and a locking pin 5 that can be pressed against the floating support column 3 is interspersed in the pin hole, and the contact surface between the locking pin 5 and the floating support column 3 is an inclined plane ; The locking pin 5 is set opposite to the output shaft of the locking cylinder 2, and the output shaft of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com