Sliding block type drilling/tapping fixture frame

A slider-type, fixture frame technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of large dynamic friction coefficient, small carrying capacity, small adjustment range, etc., achieve small dynamic and static friction coefficient, large carrying capacity, meet The effect of high precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

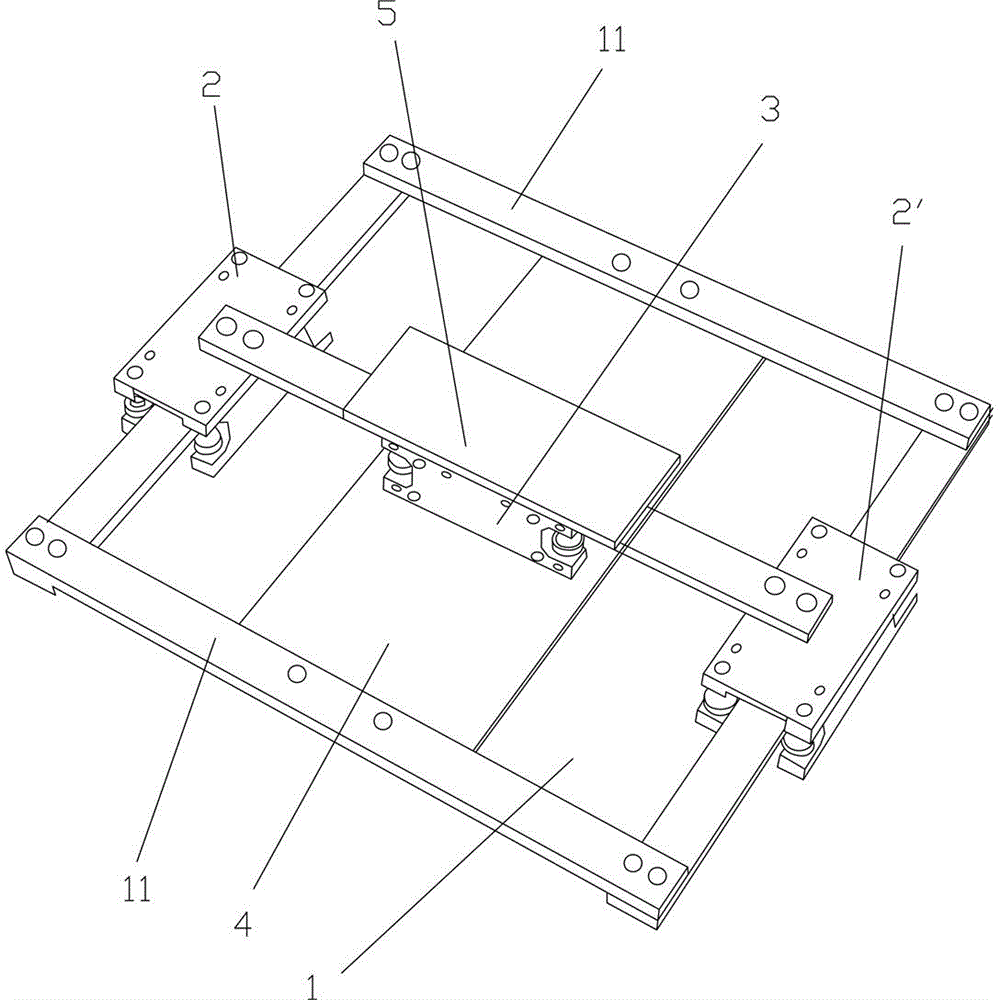

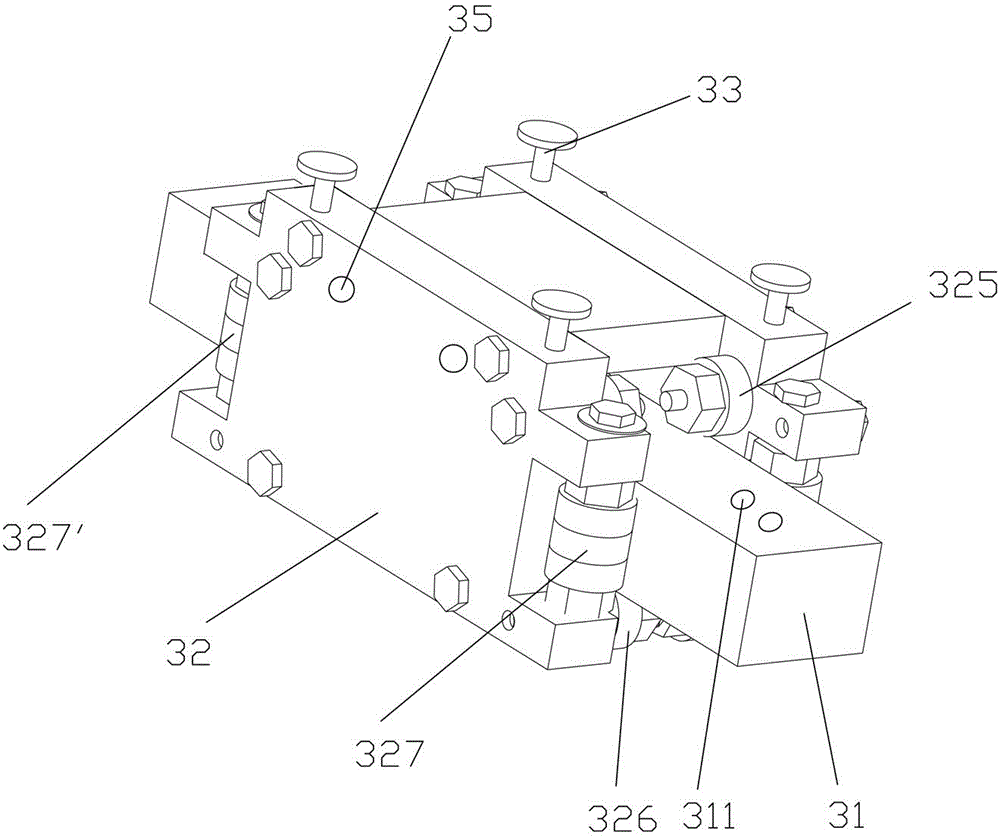

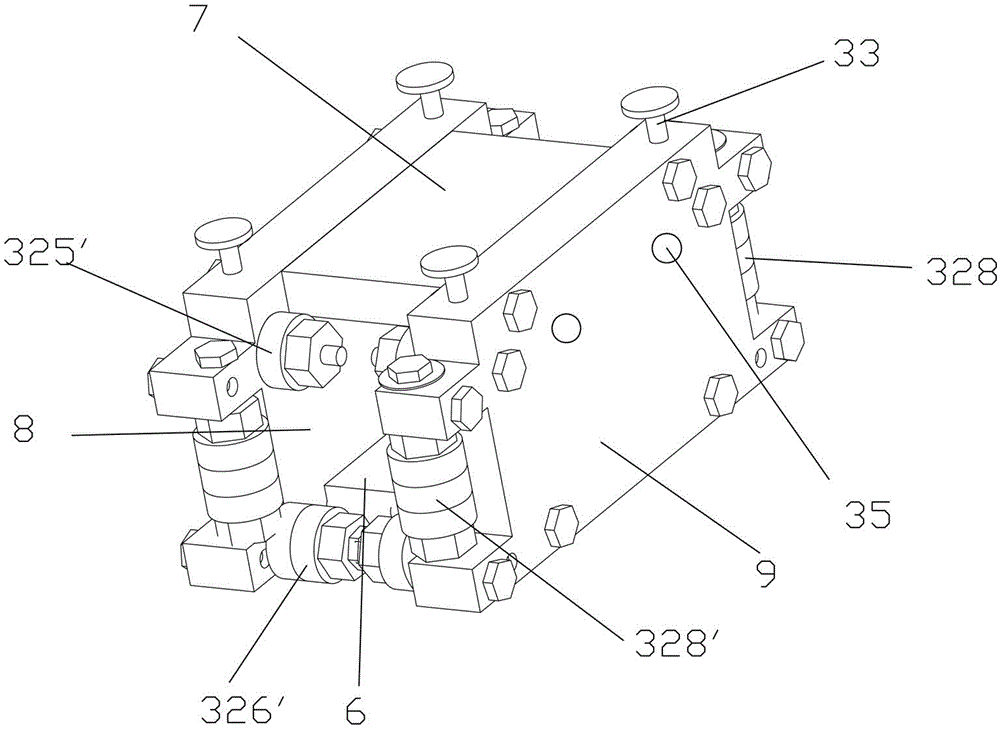

[0023] refer to Figure 1~Figure 7 , a slider-type drilling / tapping fixture frame, characterized in that it includes a base 1, and the base 1 is composed of fixed rectangular guide rails of left and right longitudinally adjustable rectangular guide rail auxiliary devices 2, 2' on both sides of the base 1 and the fixed truss 11, the left and right longitudinal rectangular guide rail auxiliary devices 2, 2' are fixedly installed with a horizontally adjustable rectangular guide rail auxiliary device 3, and the left and right longitudinal rectangular guide rail auxiliary devices 2, 2' are connected to the horizontal The structure of the adjustable rectangular guide rail auxiliary device 3 is the same, wherein the horizontally adjustable rectangular guide rail auxiliary device 3 includes a rectangular guide rail 31, and a slide block 32 is movably sleeved on the rectangular guide rail 31, and the inner side of the slide block 32 is provided with a contact with the guide rail 31. Ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com