Gravure printing and plate making method for decorative paper

A technology of gravure printing and decorative paper, applied in printing, printing device, printing plate preparation, etc., can solve the problems of high cost of decorative paper for building materials, increase of special equipment process, lack of plasticity, etc., and achieve the effect of increasing the aesthetics of decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

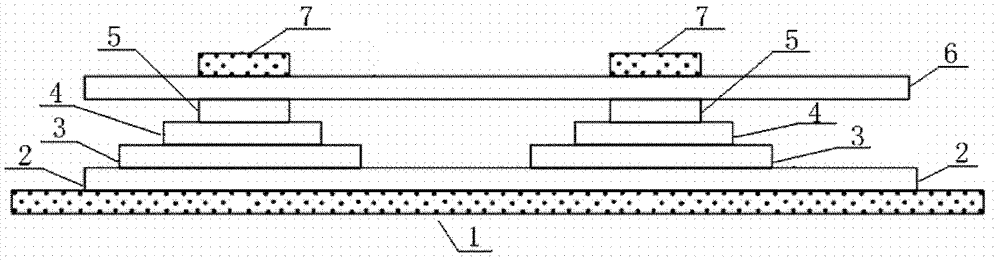

[0015] Such as figure 1 As shown, the printing layer from bottom to top is substrate 1, background color 2, common spot colors 3, 4, 5, full-page printing bright coating 6, and matte coating 7 (the printing pattern is a positive image, that is, Conduit version), forming a visual three-dimensional effect due to the change of brightness and dumbness.

Embodiment 2

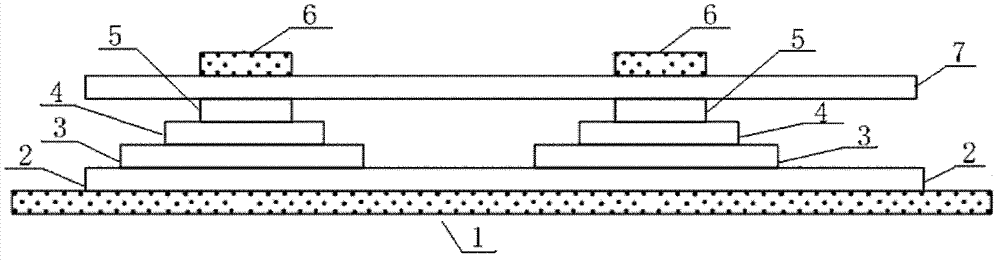

[0017] Such as figure 2 As shown, the printing layer from bottom to top is substrate 1, background color 2, ordinary spot color 3, 4, 5, full-page printing matte coating 7, and glossy coating 6 (the printing pattern is a negative image, that is, The part that does not contain the catheter), forming a visual three-dimensional effect due to the change of brightness and dumbness.

Embodiment 3

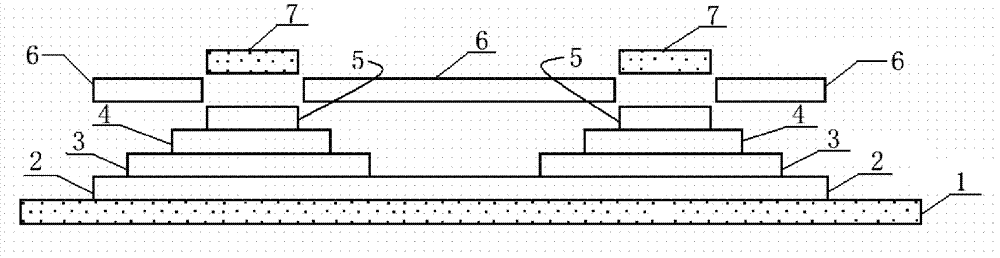

[0019] Such as image 3 As shown, the printing layer from bottom to top is substrate 1, base color 2, common spot colors 3, 4, 5, glossy coating 6 (negative version), matte coating 7 (positive version).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com