Diatomite foot pad and preparation method thereof

A technology of diatomite and foot pads, applied to carpets, etc., can solve the problems of affecting the interior decoration effect, weakening the effect of continuous use, and the diatomite is easy to melt and fall off, so as to facilitate mutual absorption, easy access, and improve decorative appearance degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

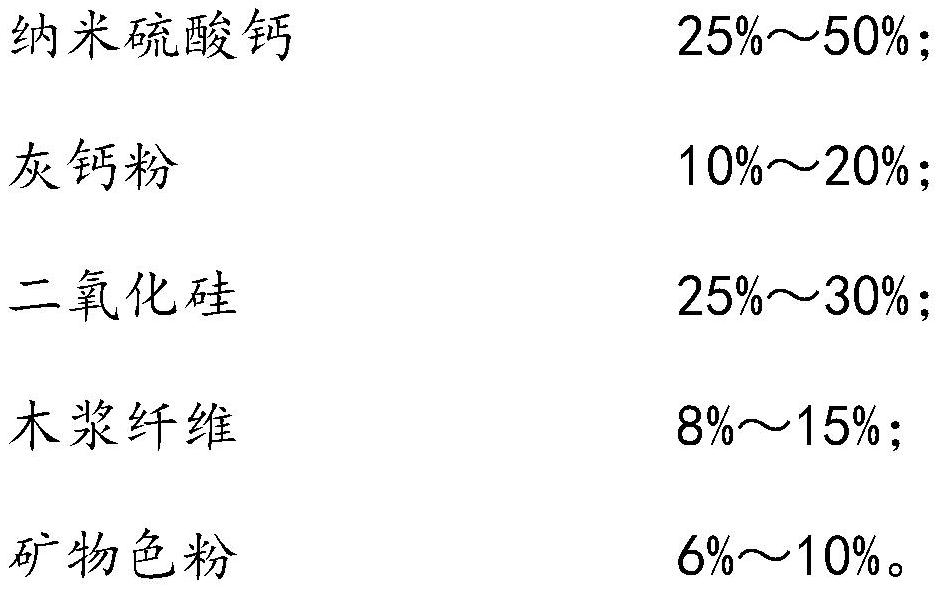

[0022] A kind of diatomite foot pad, comprises the raw material composition of following percentage by weight:

[0023]

[0024] Wherein, nano calcium sulfate is 25% (40% or 50%); Ash calcium powder is 20% (15% or 10%); Silica 30% (29% or 25%); Wood pulp fiber 15% (9 % or 8%); mineral toner 10% (7% or 6%). Its content can make the diatomite foot pad more absorbent, more suitable for use as a foot pad in the bathroom.

[0025] A preparation method of a diatomite foot pad, comprising the following steps:

[0026] a: take by weighing nanometer calcium sulfate, gray calcium powder, silicon dioxide, wood pulp fiber and mineral color powder by above-mentioned raw material percentage, fully stir 1 hour by high-speed mixer, then prepare semi-finished product by flow-flow molding;

[0027] b: The obtained semi-finished product is pre-pressed by a press, the pressure is controlled at 10MPa, and then pre-oxygenated for 1-1.5 hours, and then put into the reactor, and the pressure is ...

Embodiment 2

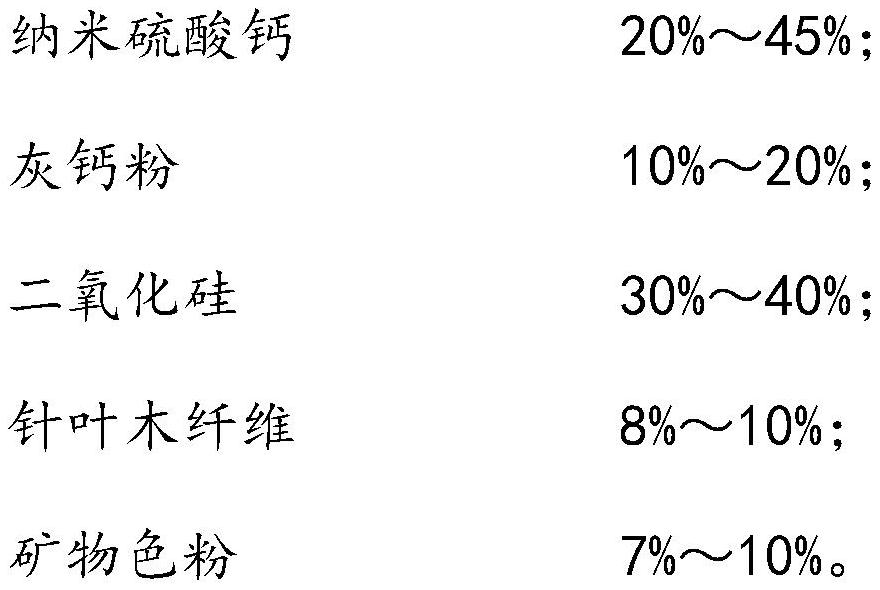

[0031] A kind of diatomite foot pad, comprises the raw material composition of following percentage by weight:

[0032]

[0033] Wherein, nano calcium sulfate is 20% (32% or 45%); Ash calcium powder is 20% (15% or 10%); Silica 40% (35% or 30%); Coniferous wood fiber 10% (9 % or 8%); mineral toner 10% (9% or 7%). Its content can make the diatomite foot pads more absorbent, and more suitable for use as foot pads in bathrooms.

[0034] A preparation method of a diatomite foot pad, comprising the following steps:

[0035] a: take by weighing nanometer calcium sulfate, gray calcium powder, silicon dioxide, wood pulp fiber and mineral color powder by above-mentioned raw material percentage, fully stir 1 hour by high-speed mixer, then prepare semi-finished product by flow-flow molding;

[0036] b: The obtained semi-finished product is pre-pressed by a press, the pressure is controlled at 10MPa, and then pre-oxygenated for 1-1.5 hours, and then put into the reactor, and the press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com