Dirt band-containing coal seam working surface mining process

A technology of working face and coal seam, which is applied in ground mining, mining equipment, earthwork drilling and mining, etc., and can solve problems such as threats to safe mining at the working face, damage to shearer cutters, and affecting production at the working face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

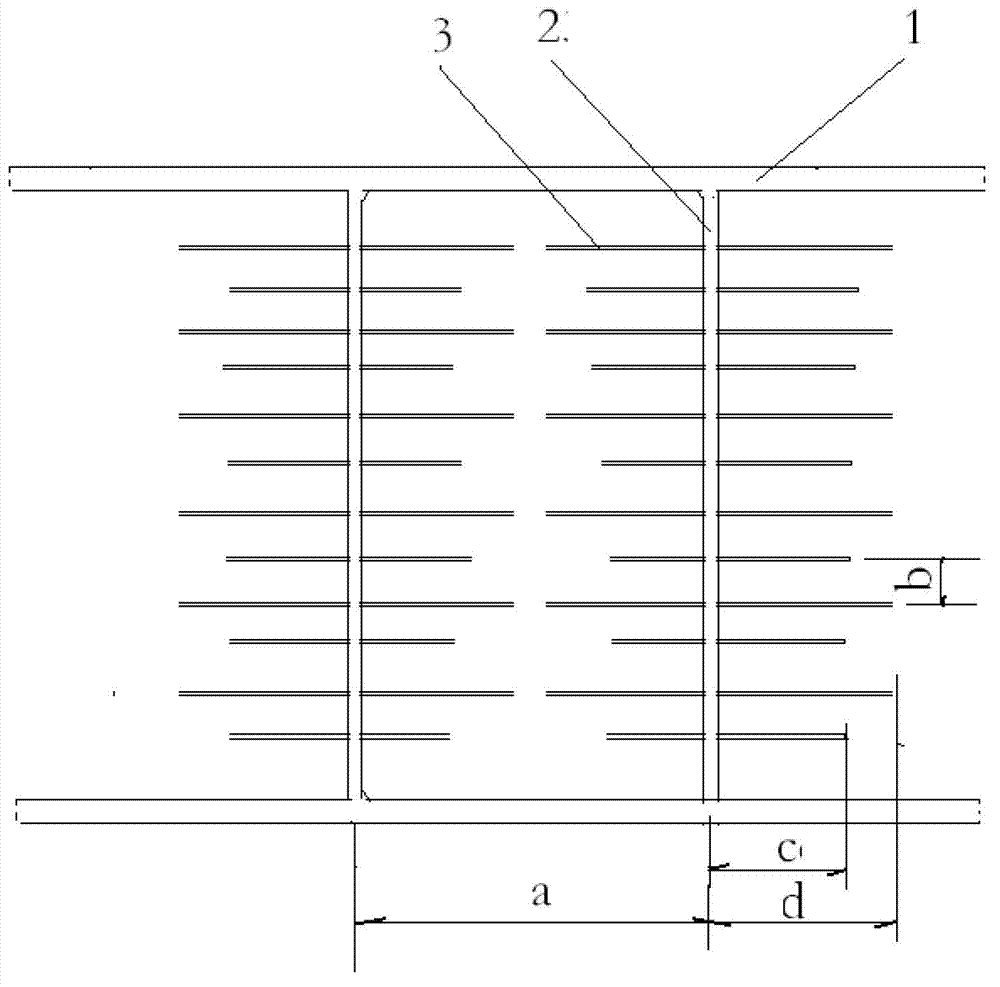

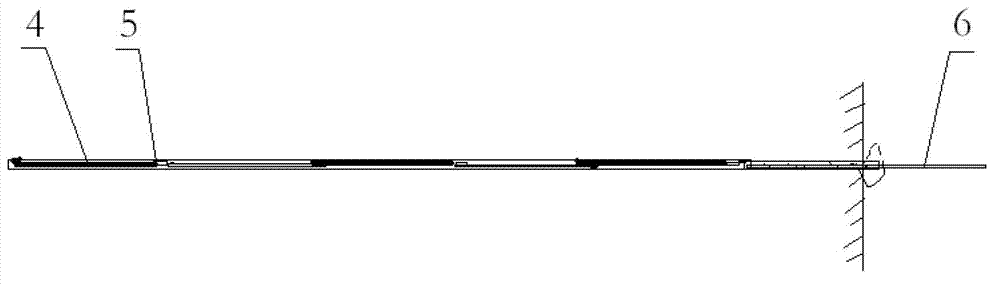

[0009] The invention discloses a coal mining process method in a gangue coal seam working face. Before mining by a shearer, firstly, a cut hole 2 is drilled into the coal seam every a=50-80 meters in the roadway 1 of the mining area, and then every cut hole 2 is made in the cut hole 2 Blast hole 3 is drilled horizontally to both sides of cut hole 2 at intervals of b=8 meters. The diameter of blast hole 3 is 42 mm. The depth of blast hole 3 is c=30 meters and d=40 meters. The two kinds of blast holes are arranged at intervals. All the blasting holes 3 are loaded with water-gel explosives 4 permitted by coal mines, the diameter of the charge roll is Φ32mm, and 1500g of charge is continuously charged at intervals of 10 meters from the bottom of the hole, and the gun head 5 of each charge section uses a section number of milliseconds to delay detonation Tube 6, all the blast holes 3 in each cutout 2 adopt millisecond delay detonator tubes 5 with different segment numbers, and the d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap