Bracket for holding lens and lens manufacturing method

A lens holding and lens technology, applied in the directions of glasses/protective glasses, glasses/goggles, installation, etc., can solve problems such as difficult operation, and achieve the effect of improving installation and excellent workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Next, an embodiment of the present invention will be described.

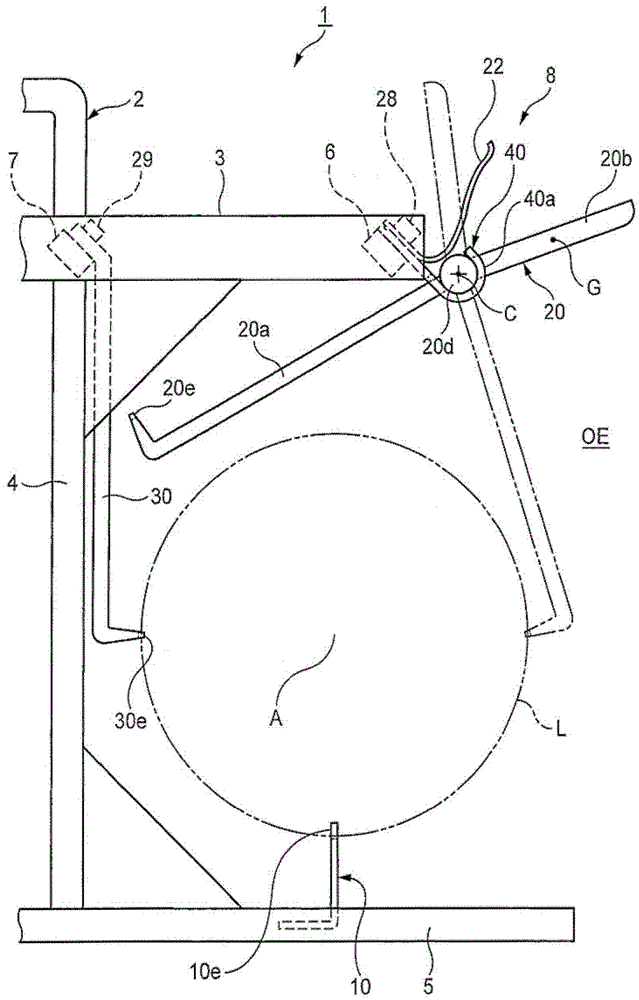

[0063] First, refer to Figure 1 to Figure 9 One embodiment of the lens holding bracket and the manufacturing method of the present invention will be described in detail.

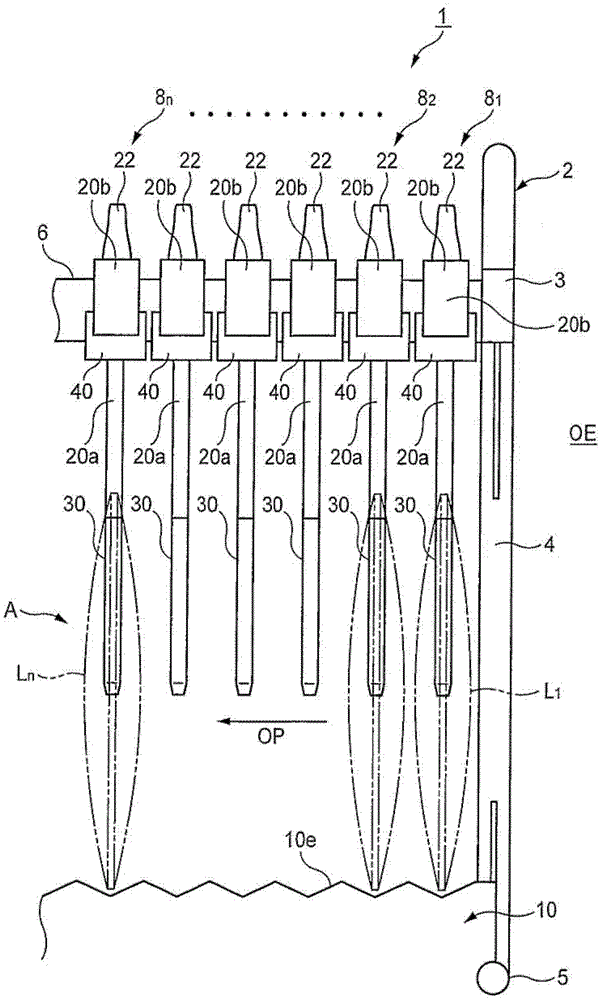

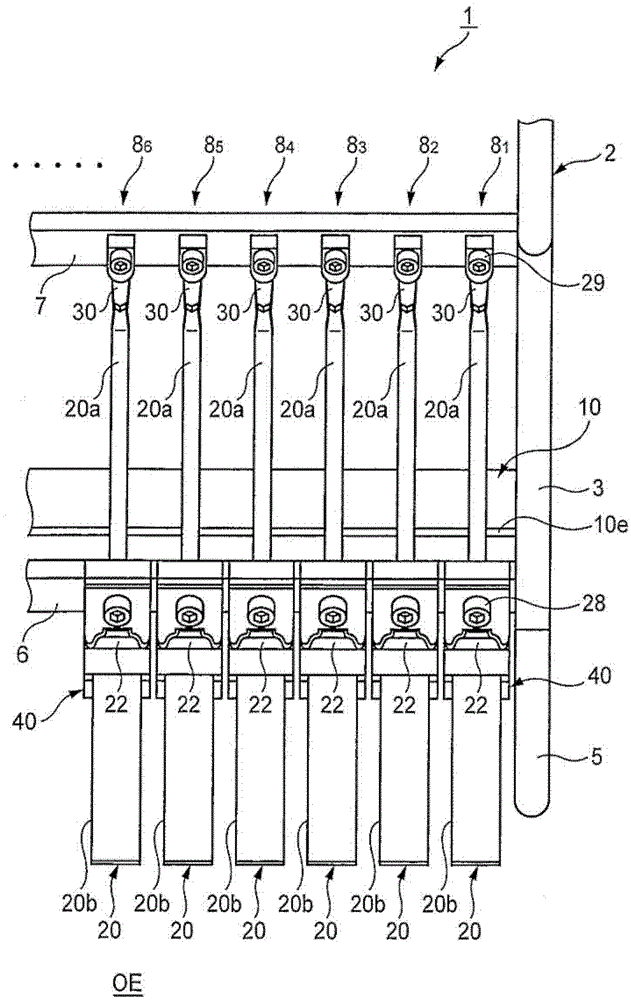

[0064] The lens holding bracket 1 of the present embodiment has, for example, an overall structure of Figure 9 As shown, a plurality of lens holding units 8 (8) are arranged on the bracket frame portion 2 1 ,8 2 ,8 3 ...8 n ) structure.

[0065] Regarding the detailed structure of the stent frame portion 2, for example figure 1 As shown, the left and right respectively have a pair of ( figure 1 in the vertical direction of the paper, figure 2 In the left and right directions) in the horizontal direction on the upper side of the bracket vertical frame portion 4 extending in the figure 1 The bracket side support frame 3 extending in the left-right direction) and the bracket bottom portion 5 extending horizontally on the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com