Heating device for cooling end of screw type energy-saving lamp

A technology for heating devices and energy-saving lamps, applied in the manufacture of ships or leading wires, etc., can solve problems such as safety hazards and heat loss, and achieve the effects of increasing the safety range, using heat energy efficiently, and avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

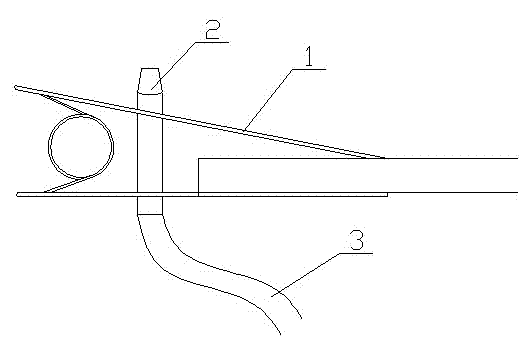

[0008] Such as figure 1 As shown, the heating device for the cold end of the spiral energy-saving lamp of the present invention includes a clamping seat (1). (2), the flame nozzle of the flame nozzle (2) is vertically upward, and the lower end of the flame nozzle (2) is connected to the gas pipeline (3). Wherein, the height of the flame ejected by the flame nozzle (2) is 8cm, and the diameter of the flame nozzle of the flame nozzle (2) is 0.5cm-1.5cm.

[0009] When the present invention is working, the operator sits on one side of the workbench, clamps the holder (1) on the edge of the workbench on the side close to the operator, checks the firmness, and ensures the fire nozzle of the fire nozzle (2) Upright, open the gas pipeline (3) and ignite, place the lamp tube to be processed on the flame ejected from the flame nozzle (2), and align the cold end of the lamp tube with the outer flame of the flame to achieve For the best heating effect, after the lamp tube is heated to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com