Semiconductor light source module, production method and substrate structure thereof

A technology of a light source module and a manufacturing method, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems that the uniformity of the substrate structure is difficult to control, occupies the space of the substrate structure, and the volume of components cannot be reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following examples are provided for detailed description, and the examples are only used as examples for illustration and will not limit the scope of protection of the present invention. In addition, some components are omitted from the drawings in the embodiments to clearly show the technical characteristics of the present invention.

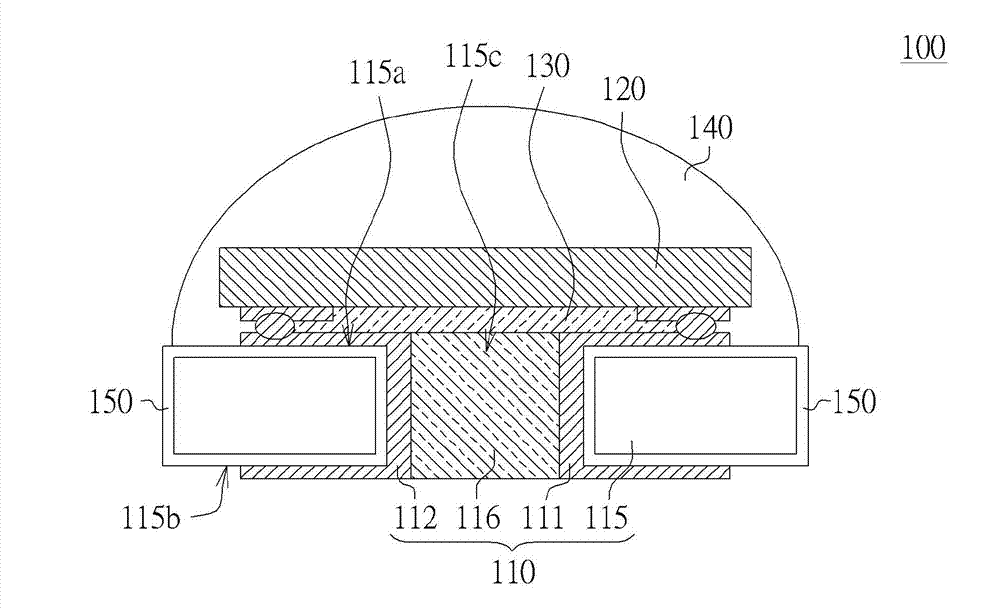

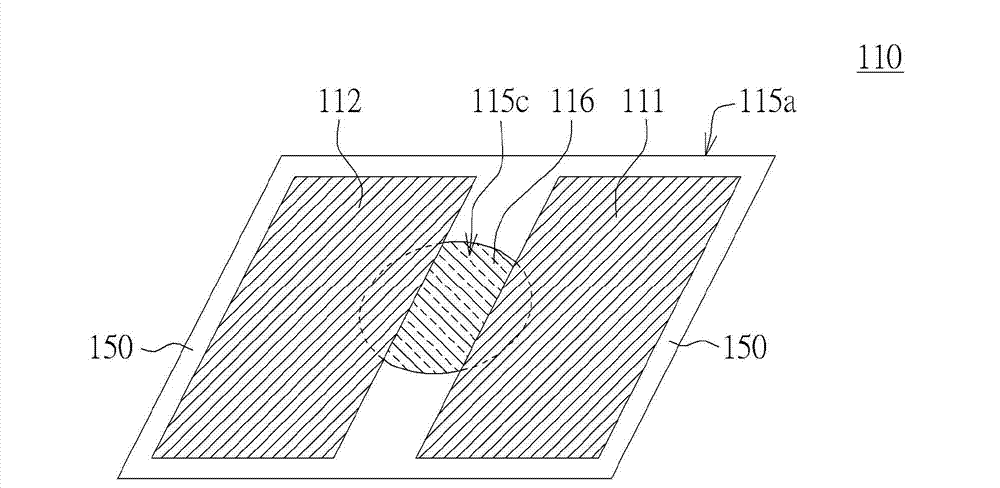

[0037] Please refer to figure 1 , which shows a schematic cross-sectional view of the semiconductor light source module 100 . The semiconductor light source module 100 mainly includes a substrate structure 110 and a light emitting diode (LED) 120 . The LED 120 is disposed on the substrate structure 110 . The light-emitting diode 120 is used to emit light, and its material is, for example, aluminum gallium arsenide (AlGaAs), aluminum gallium phosphide (AlGaP), aluminum indium gallium phosphide (AlGaInP), gallium arsenide phosphide (GaAsP), gallium phosphide (GaP ), gallium nitride (GaN), indium gallium nitride (InGaN), or aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com