Photocatalyst air purification module and air purifier formed thereby

A technology of air purification and photocatalyst, which is applied in the field of photocatalyst air purification module and the air purification device composed of it, can solve the problems of low quantum efficiency of catalytic reaction, low utilization rate of light source, and guaranteed air flow, so as to enhance the effect of air purification and improve Lighting efficiency, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

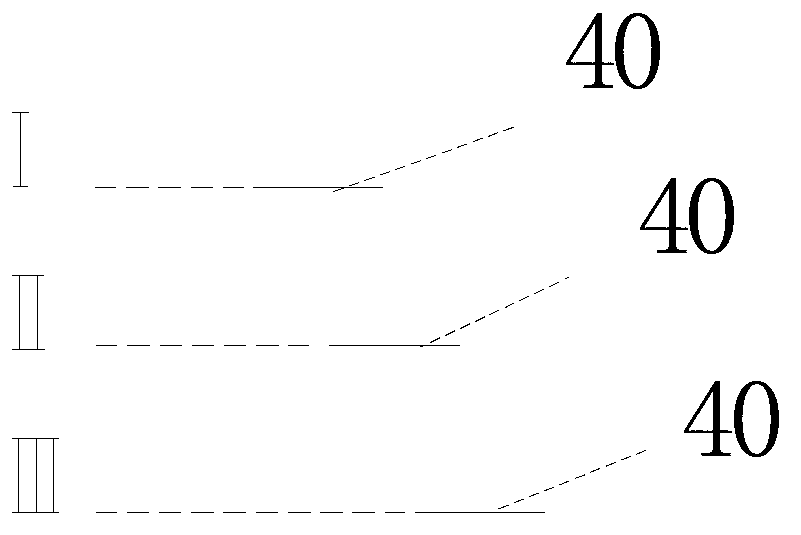

[0030] The photocatalyst air purification module of the present invention is composed of three photocatalyst carriers and a light source. The photocatalyst carrier is provided with a photocatalyst layer. The photocatalyst carrier is made of ceramics. The photocatalyst layer is a nano-titanium dioxide layer. on the photocatalyst carrier. Such as figure 1 As shown, the photocatalyst carrier is staggered in such a way: three photocatalyst carriers 40 are arranged in three layers, and the space between layers is parallel, and the photocatalyst carrier 40 between adjacent two layers has a vertical projection on the same plane. Overlapping (the plane where the vertical projection is located is parallel to the space of the photocatalyst supporting layer), but not completely overlapping.

[0031] The photocatalyst air purification modules arranged in this way are arranged in the casing, and an air inlet and an air outlet are arranged on the casing, and the light source is connected t...

Embodiment 2

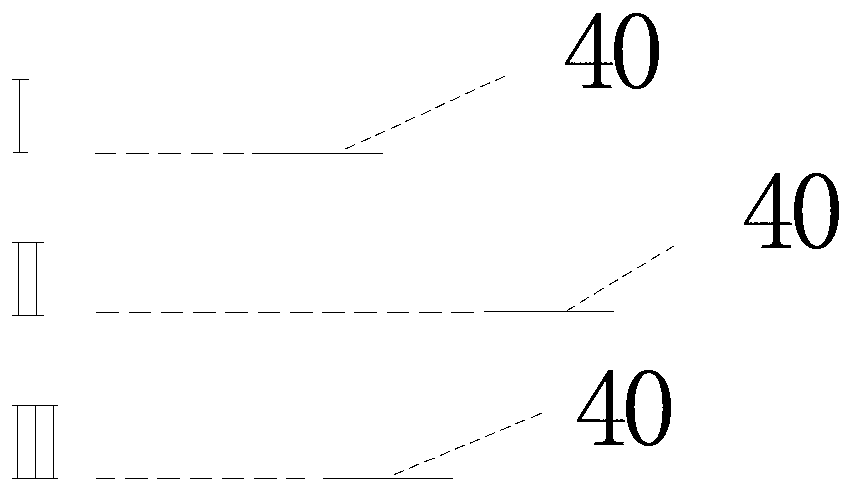

[0036] The photocatalyst air purification module of the present invention is composed of three photocatalyst carriers and a light source. The photocatalyst carrier is provided with a photocatalyst layer. The photocatalyst carrier is made of ceramics. The photocatalyst layer is a nano-titanium dioxide layer. on the photocatalyst carrier. Such as figure 2 As shown, the photocatalyst carrier is staggered in such a way: three photocatalyst carriers 40 are arranged in three layers, and the space between the layers is parallel, and the photocatalyst carrier 40 between adjacent two layers has no vertical projection on the same plane. Overlapping (the plane where the vertical projection is located is parallel to the space of the photocatalyst carrier layer), the vertical projections of the photocatalyst carrier 40 in the interlayer (such as the first layer and the third layer) on the same plane overlap, but do not overlap.

[0037] The photocatalyst air purification modules arranged...

Embodiment 3

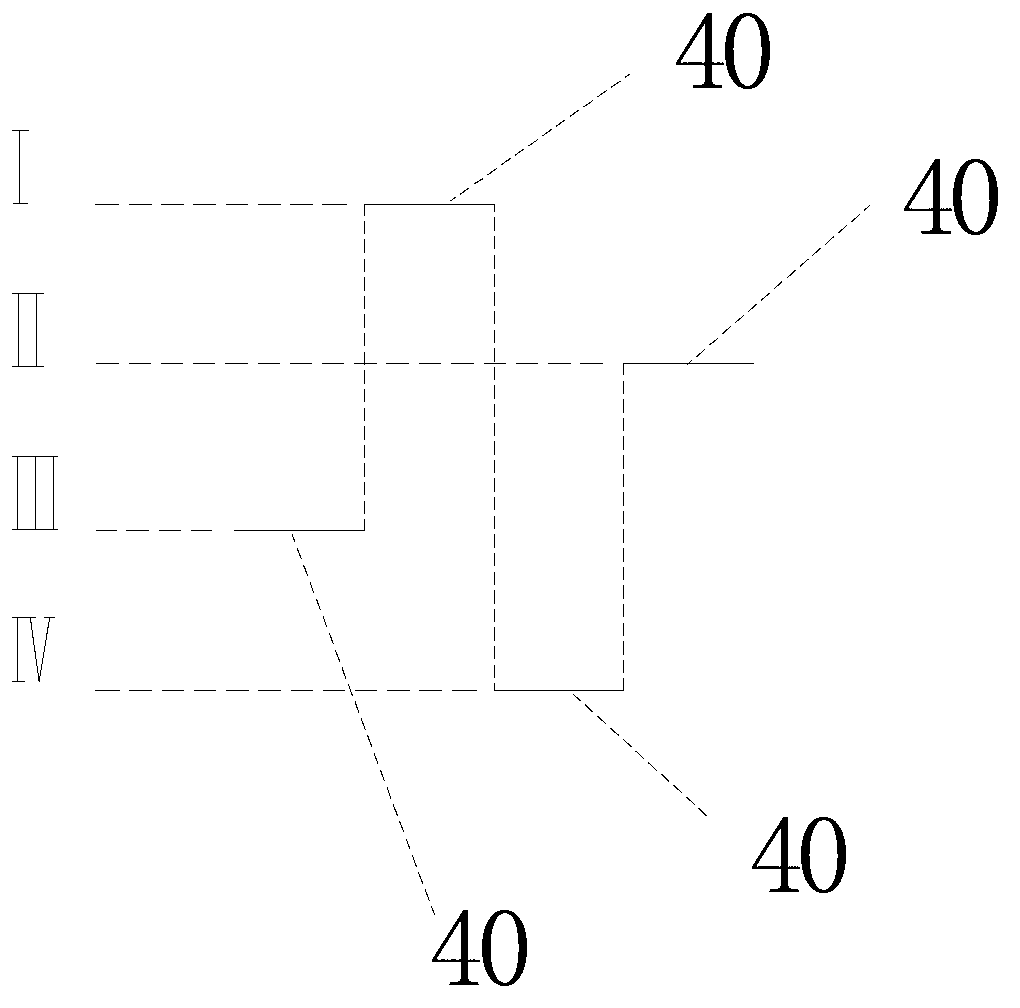

[0042] The photocatalyst air purification module of the present invention is composed of four photocatalyst carriers and a light source. The photocatalyst carrier is provided with a photocatalyst layer. The photocatalyst carrier is made of ceramics. The photocatalyst layer is a nano-titanium dioxide layer. irradiated on the photocatalyst carrier. Such as image 3 As shown, the photocatalyst carrier is staggered in such a way: four photocatalyst carriers 40 are arranged in four layers, and the space between layers is parallel, and the vertical projections of any two layers of photocatalyst carriers 1 on the same plane do not overlap, and The vertical projections of all the photocatalyst carriers on the same plane are seamlessly connected, and the plane where the vertical projections are located is parallel to the space of the photocatalyst carrier layers. The four photocatalyst carriers 40 are all square, and the vertical projection of the four photocatalyst carriers 40 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com