Automatic spraying protection process for stone slab

A technology of automatic spraying and stone plate, applied in the direction of coating, device for coating liquid on the surface, surface pretreatment, etc., which can solve the problems of uneven coating, low efficiency and poor economic benefit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Prepare the protective agent according to the material of the specific stone plate, add the prepared protective agent to the liquid storage tank, and then atomize the protective agent to the nozzle for spray protection through compressed air.

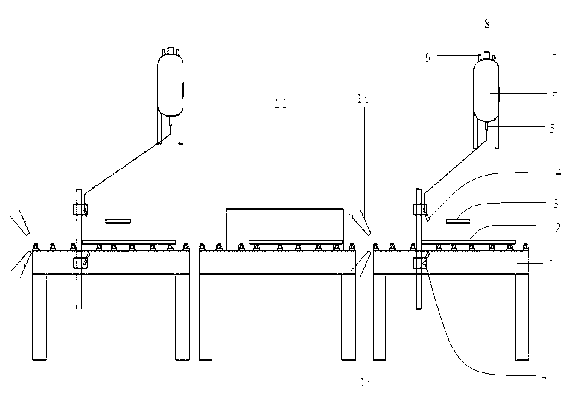

[0027] Such as figure 1 As shown, the stone slab automatic spraying protection process of the present invention, while the stone slab 2 is transported on the transport frame 1, the stone slab 2 is sprayed, air-dried, and dried, and it is characterized in that it includes the following steps:

[0028] i) Atomize the protective agent by compressed air;

[0029] ii) Spray the atomized protective agent on six faces of the stone plate 2;

[0030] iii) air-dry the slate 2 materials protected for the first time with blower fan 10;

[0031] iv) drying the protected stone slabs with drying box 11;

[0032] v) Spray the dried stone plate on six sides again;

[0033] vi) Air-dry the stone slab with fan 10 again.

[0034] As a preferre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com