Different-diameter screw cold feed vented extruder

A venting extruder and cold feeding technology, which is applied in the field of rubber cold feeding venting extruders, can solve the problems of unstable venting effect, low productivity and poor adaptability of venting extruders, and achieve Increase the free surface area, improve the extrusion stability, and the effect of stable production capacity balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

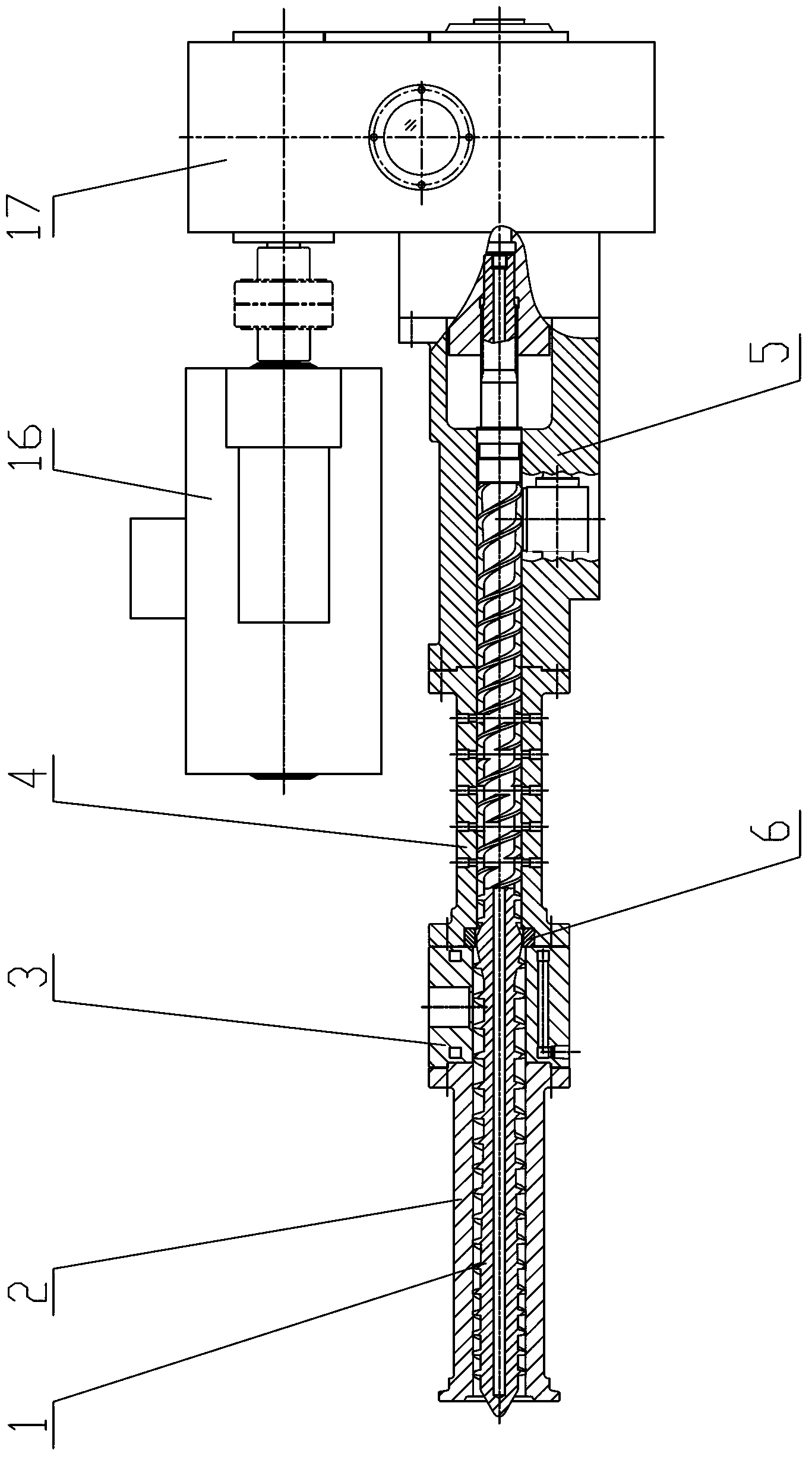

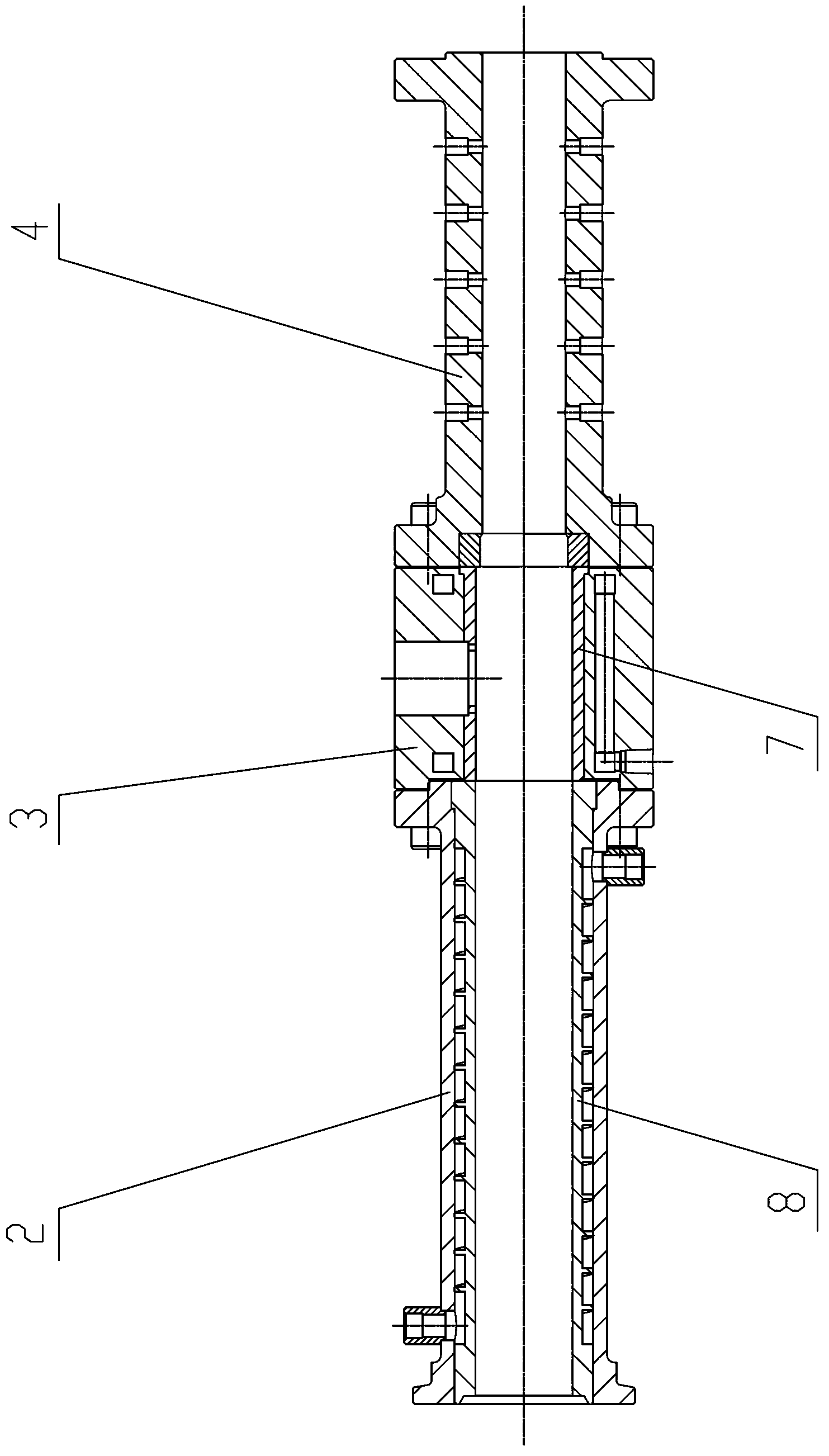

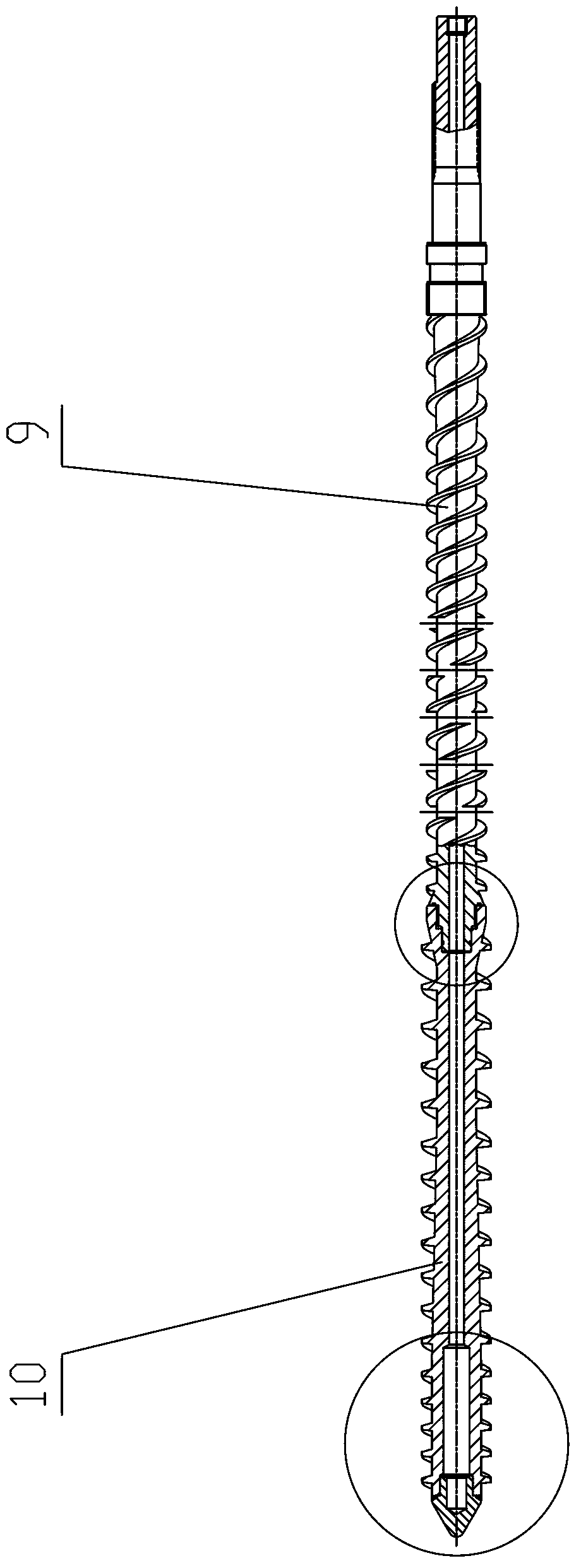

[0029] The different-diameter screw cold-feed exhaust extruder of the present invention includes a second-stage screw 1, a machine barrel, a feeding seat 5, a motor 16 and a reduction box 17. The feeding seat 5 is fixed on the output end of the reduction box 17, the input shaft of the input end of the reduction box 17 is connected to the output shaft of the motor 16, and the end of the barrel is connected to the feeding seat 5 (the side pressure is provided on the feeding seat 5). roller, with forced feeding function), the front end of the barrel is connected to the extruder head, the second-stage screw 1 is placed in the barrel and the feeding seat 5, and the shaft end of the second-stage screw 1 is connected to the output shaft of the output end of the reduction box 17 , the power of the motor 16 is transmitted to the second-stage screw 1 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com