Automatic cigarette supply device

A technology of automatic supply and cigarette packs, applied in the field of cigarette manufacturing, can solve the problem that the production capacity of the transparent paper packaging machine outside the box and the rigid strip packaging machine cannot be fully utilized, and the packaging speed of the transparent paper packaging machine outside the box and the rigid strip packaging machine are restricted. Reduce equipment production efficiency and other issues, achieve the effect of improving equipment utilization, saving manpower and material resources, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

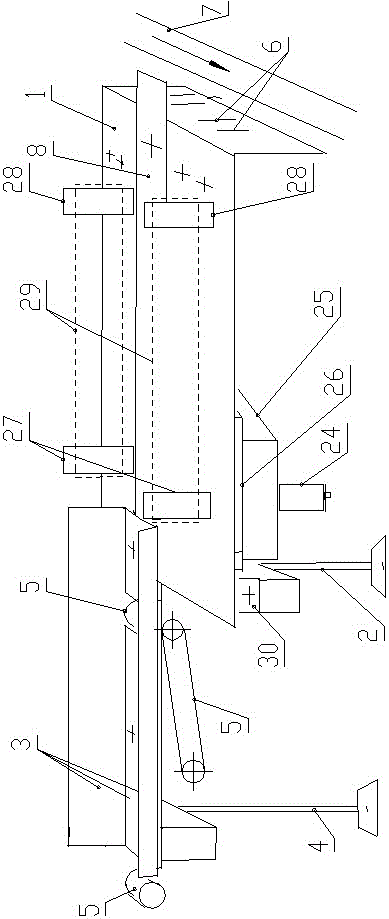

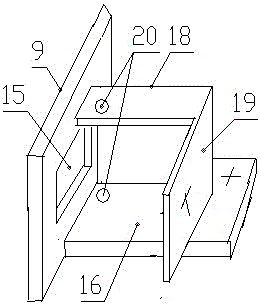

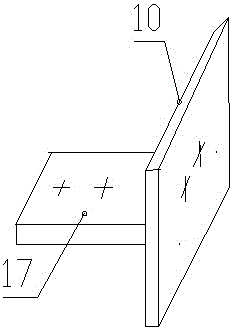

[0028] Such as figure 1 As shown, a kind of cigarette bale automatic supply device of the present invention comprises support plate 1; With the conveying direction of cigarette bale on support plate 1 as forward direction, the rear end of support plate 1 is connected with first leg 2 downwards, support plate 1. The rear end of the U-shaped groove 3 is connected to the rear with a horizontally arranged U-shaped groove 3, and the rear end of the U-shaped groove 3 is connected downward with the second leg 4; the bottom of the U-shaped groove 3 is provided with a conveyor belt device 5 for transporting cigarette packs. The distance between the left and right side walls of the slot 3 is equal to the length of the cigarette pack; the bottom of the U-shaped slot 3 extends forward integrally with a cigarette pack slide 8 whose width is equal to the length of the cigarette pack; the front end of the bracket plate 1 passes through the M8 bolt The bolt hole 6 is fixedly connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com