Traction balance mechanism for traveling car on track

A technology of balance mechanism and mobile trolley, which is applied in the field of traction balance mechanism and balance device of material transport mechanism, which can solve problems such as safety accidents, deviation of material transport vehicle, breakage of traction rope, etc., and achieve convenient operation, safe operation and reasonable structure , the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

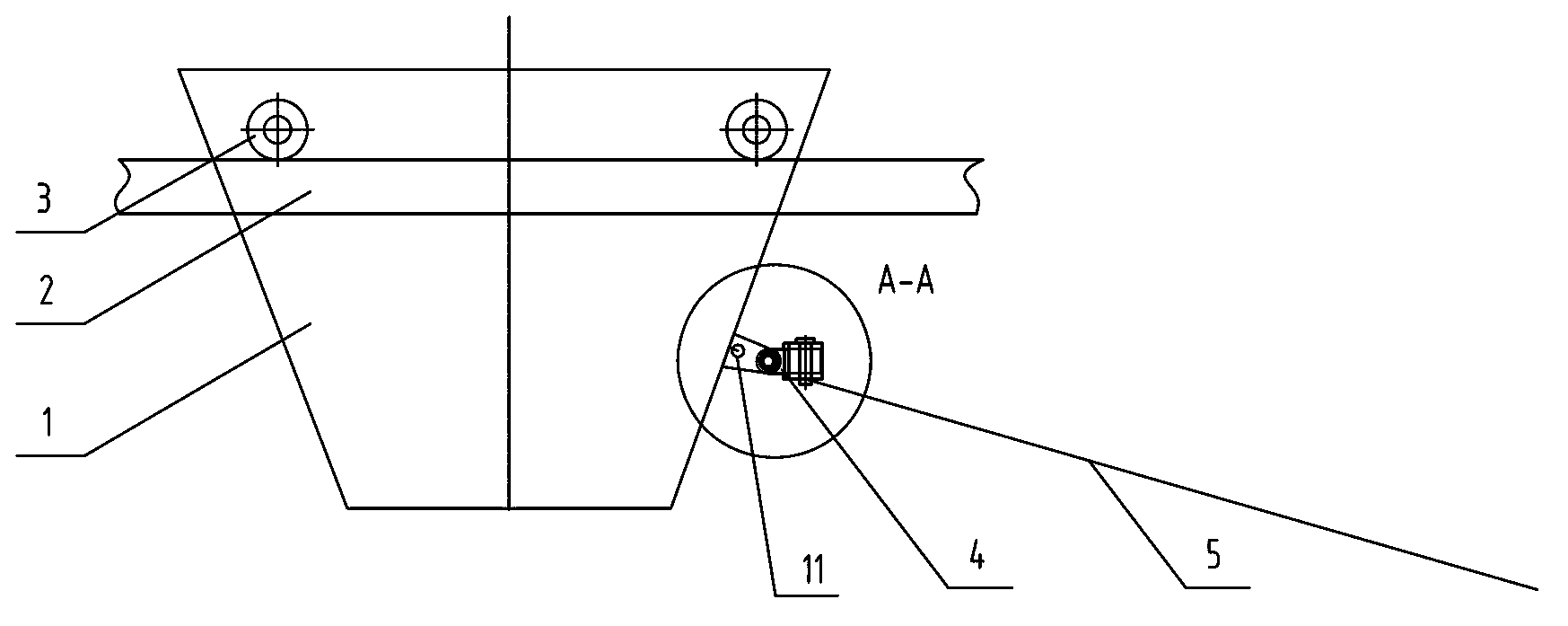

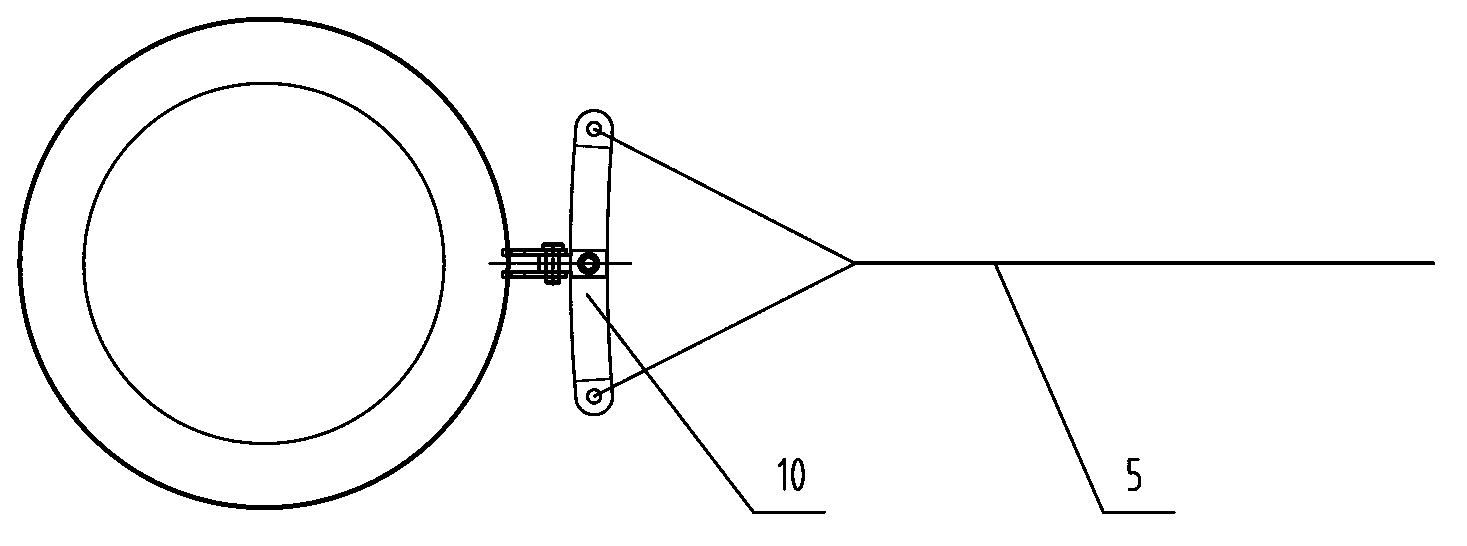

[0012] Such as Figure 1~3 As shown, a traction balance mechanism for moving a trolley on a track, which includes a trolley 1, on which a number of running wheels 3 are arranged as required, the running wheels 3 are arranged on both sides of the trolley 1, and the track 2 is below the running wheels 3. The trolley 1 moves forward on the track 2 through the running wheels 3 . A connecting plate 11 is welded at the front end of the trolley 1, and a through hole is provided at the front end of the connecting plate 11. The bolts are fixed to the material balance mechanism 10 through the through hole. The front end of the material balance mechanism 10 is fixed with a steel wire rope 5, which is directly pulled Car 1 moves forward on track 2.

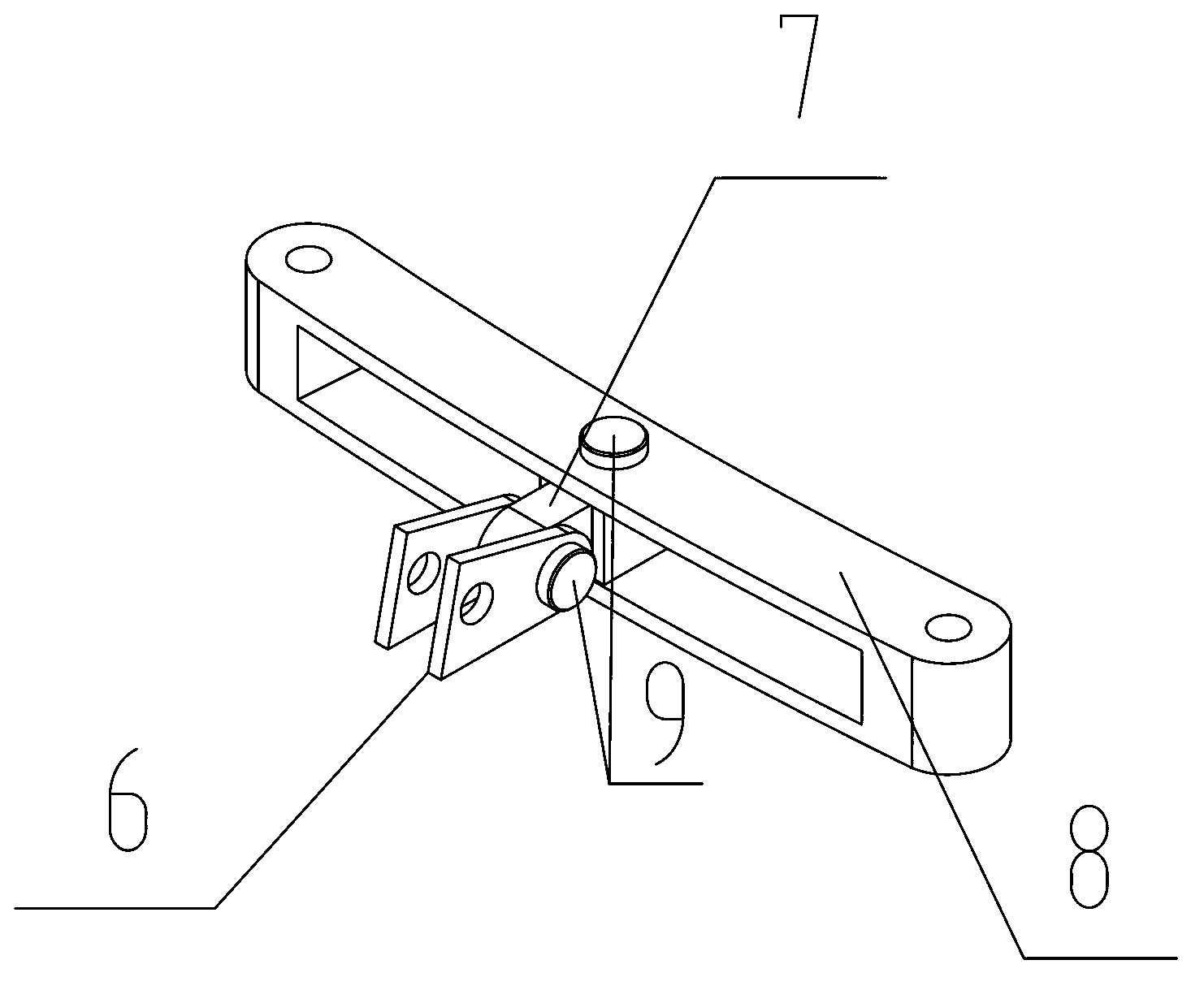

[0013] The material delivery balance mechanism 10 is made up of two fixed plates 6 , a movable block 7 and a swing block 8 . The size and shape of the fixing plate 6 are similar to that of the connecting plate 11. The front end of the fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com