Base plate used in handling packing case

A packaging box and backing technology, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of bumping and scratching of handles, lowering product grades, etc., to prevent bumping of handles, low production cost, and large number of packages Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

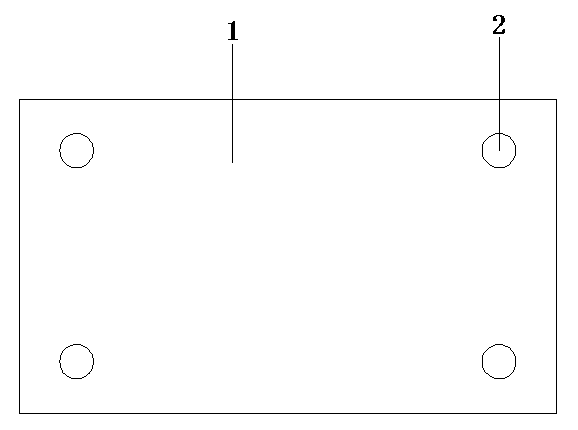

[0014] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a plate body 1, the size of which is the same as the inner diameter of the packaging box, and two symmetrical perforations 2 are provided at the four corners of the plate body 1; the diameter of the perforation holes 2 is 15 mm.

[0015] Product technical indicators: Burst resistance ≥ 686g / m2, edge compressive strength ≥ 4.5N / m, adhesive strength ≥ 588N / m.

[0016] After the board body 1 with the same size is put into the carton, the surroundings of the carton and the board body 1 are in an interference fit state, and there will be no bumping between the handles due to long-term bumpy handles leaking into the bottom layer, which is more suitable for long-distance transportation. Moreover, the packaging quantity is large and the cost is low.

[0017] The structure of the plate body 1 is designed with a 15mm perforation 2, which is convenient for movement during pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com