Feeding mechanism

A technology of feeding mechanism and material roller, which is applied in the direction of thin material processing, coiling, transportation and packaging, etc., which can solve the problems of large scrap volume of semi-finished products, unsatisfactory material connection method, and increased manufacturing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

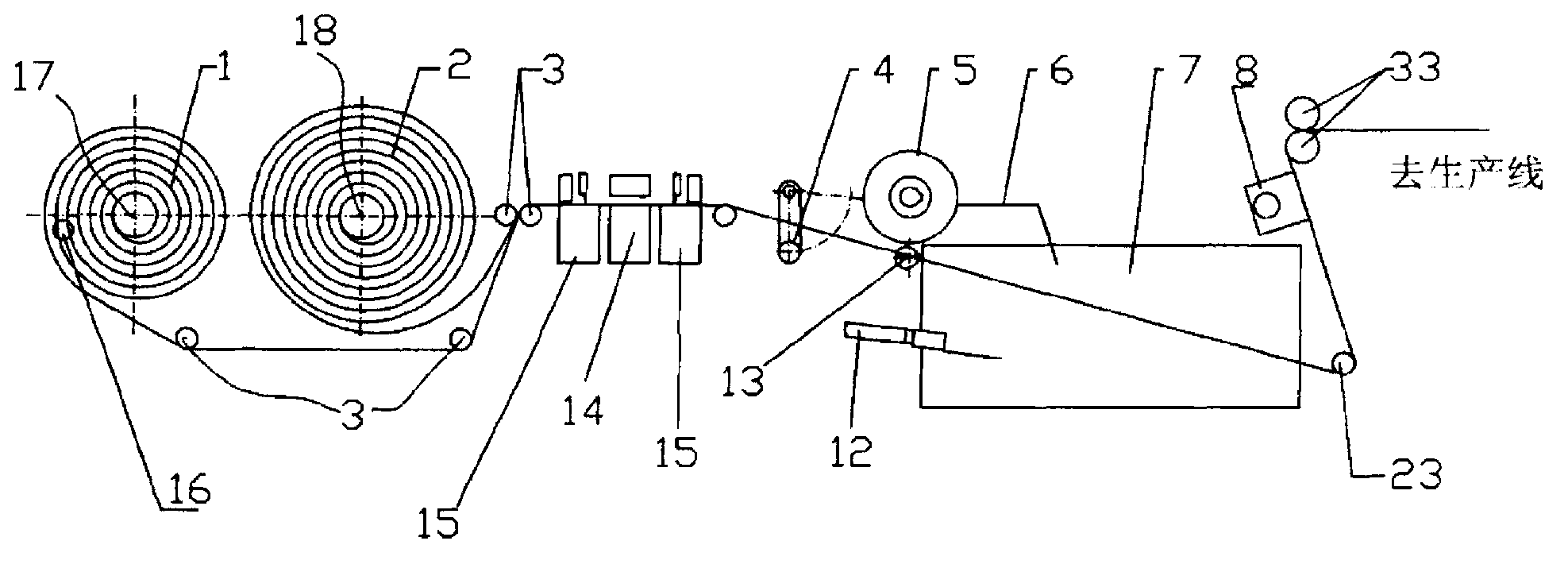

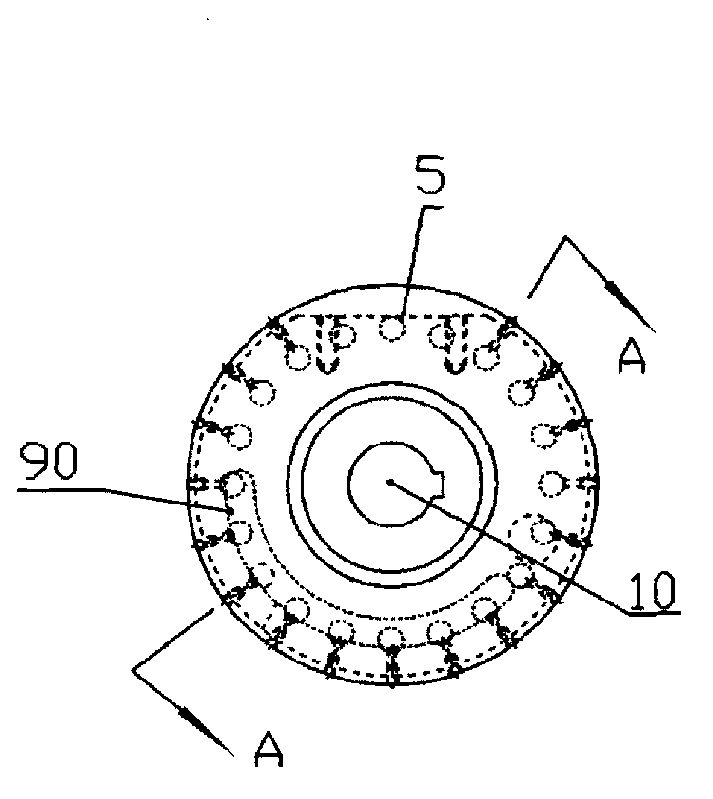

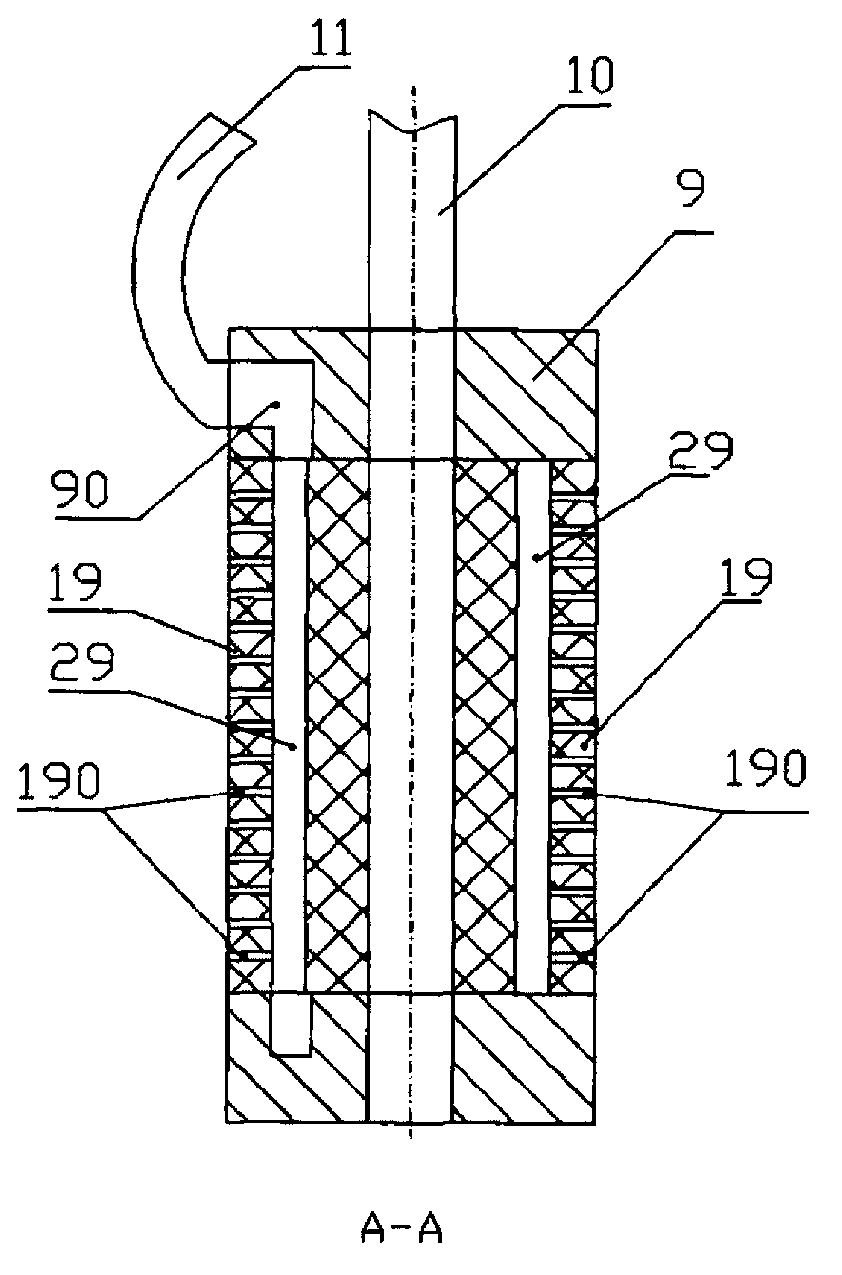

[0034] See Figure 1-4 , the feeding mechanism of the disposable sanitary product production line of the present embodiment, comprising: static material receiving mechanism 14, fast discharge mechanism, the first material roller 17 and the first material roller 17 that is used to set coiled material to provide production material to disposable sanitary product production line The second material roller 18; the quick discharge mechanism is used to quickly discharge the first coil material 1 that is about to be used up on the first material roller 17; the static material receiving mechanism 14 is used for the described first coil that has been discharged quickly The end of a coil 1 is connected with the head end of the second coil 2 on the second material roller 18, so as to continuously supply production materials to the production line of disposable hygiene products.

[0035] As another embodiment, in order to reduce the space occupied by the feeding mechanism, only one materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com