Down feather filling machine

A technology of down filling machine and buffer device, which is applied in the field of down filling machines, can solve the problems of single function and inability to meet the processing operation of down jackets, and achieve the effect of wide adaptability and avoiding down splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

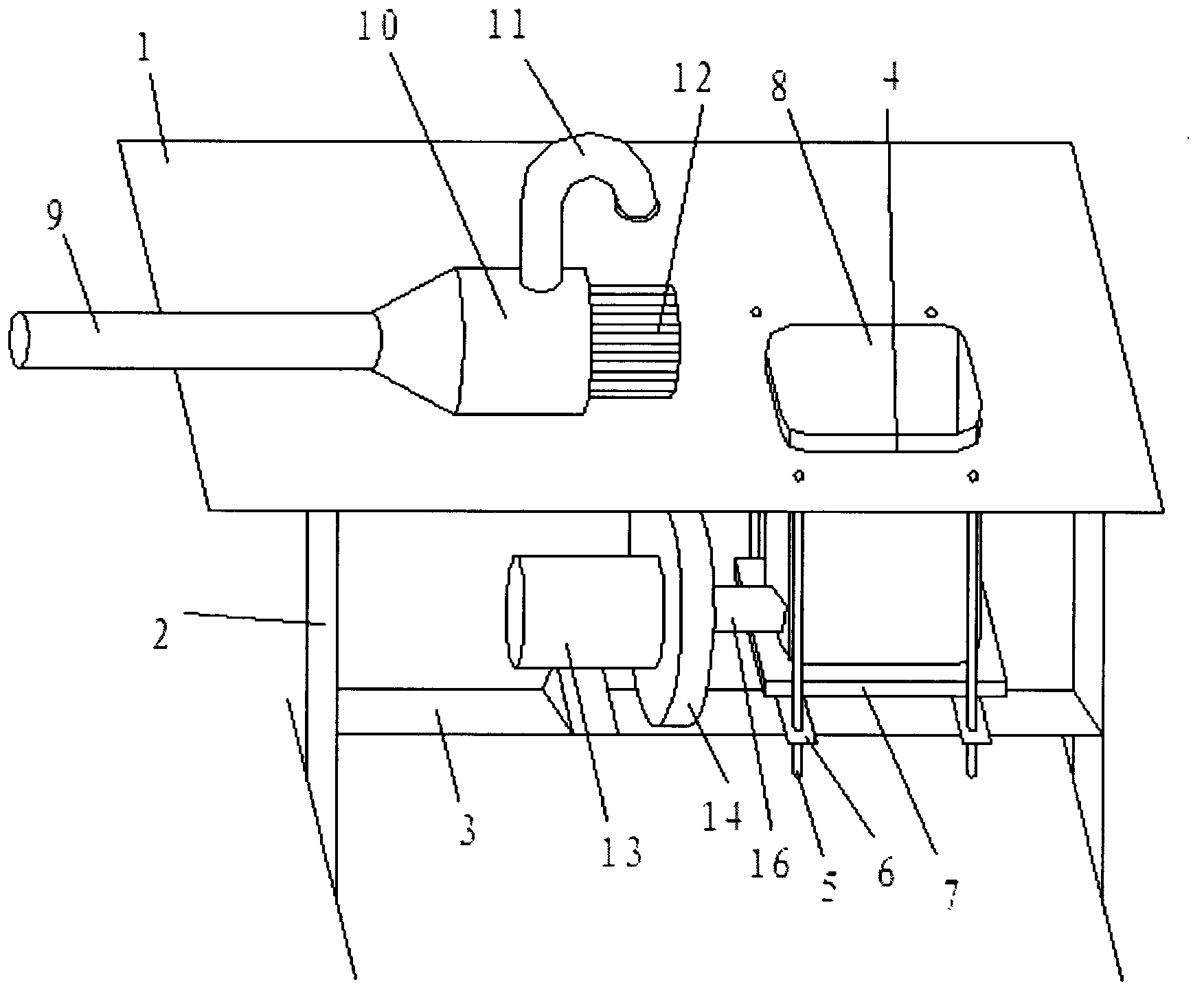

[0029] see figure 1 , the operating table 1, the two sides of the bottom are provided with uprights 2, and the uprights 2 are connected by cross bars 3.

[0030] The buffer device 10 is placed on the operating platform 1 and is connected with the blower type feeding device through the feeding pipe 11 , and the feeding pipe 11 passes through the operating platform 1 .

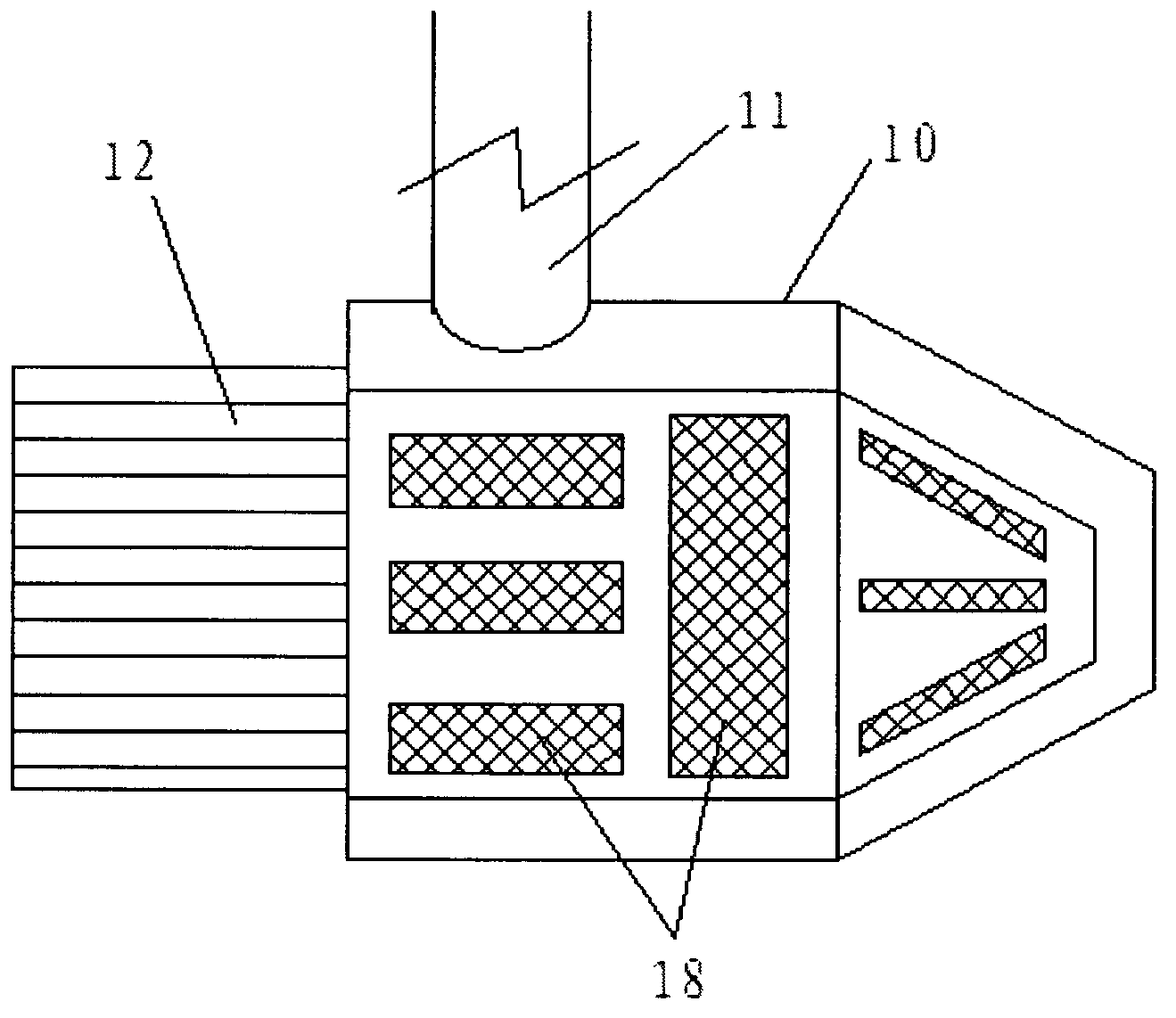

[0031] see figure 2 A side perpendicular to the discharge direction of the feed pipe 11 in the buffer device 10 is provided with several air outlets 18, and the air outlet 18 is equipped with a mesh fabric, and the mesh fabric is preferably a 30-100 mesh steel mesh.

[0032] Due to the design of the air outlet, after the airflow brings the down into the buffer device 10, the airflow is directly discharged from the air outlet 18, which avoids the down filling process in which the down is directly brought into the product by compressed air, resulting in splashing and damage. Phenomenon.

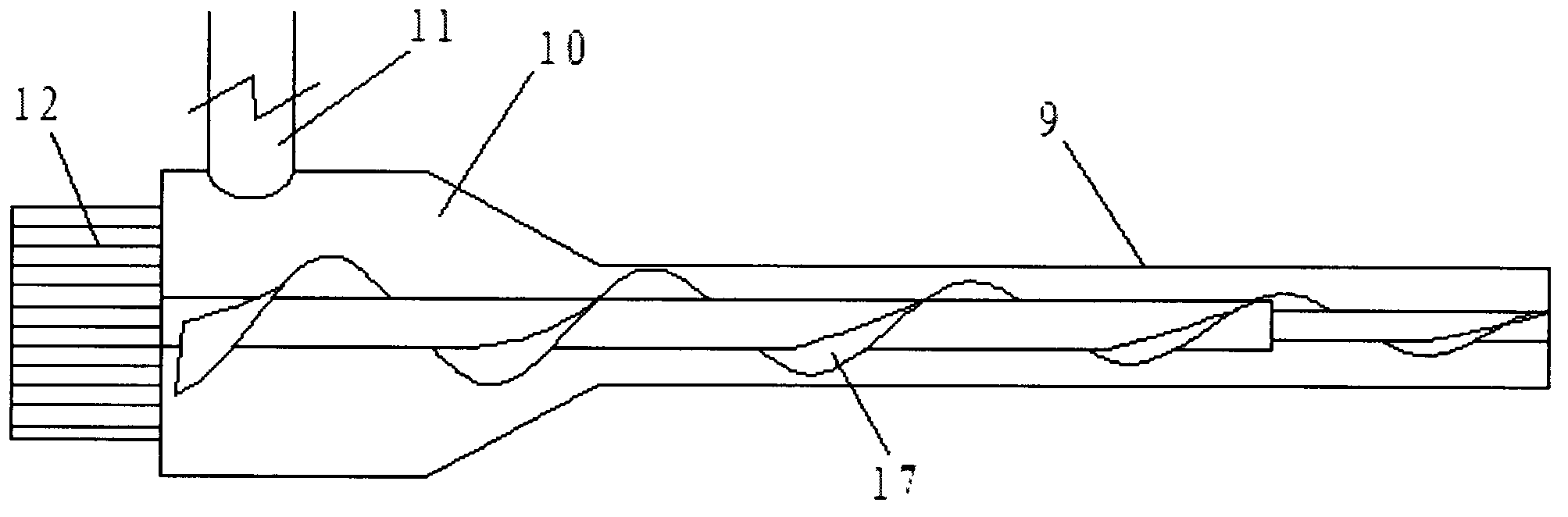

[0033] see image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com