Installation method for testing tube used for testing internal force of pre-stress tubular pile with slide micrometer

A technology of prestressed pipe pile and installation method, which is applied in the test of foundation structure, construction, foundation structure engineering and other directions, can solve the problem of inability to bury the measuring pipe, etc., and achieves reasonable method design, simple installation method and reliable installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

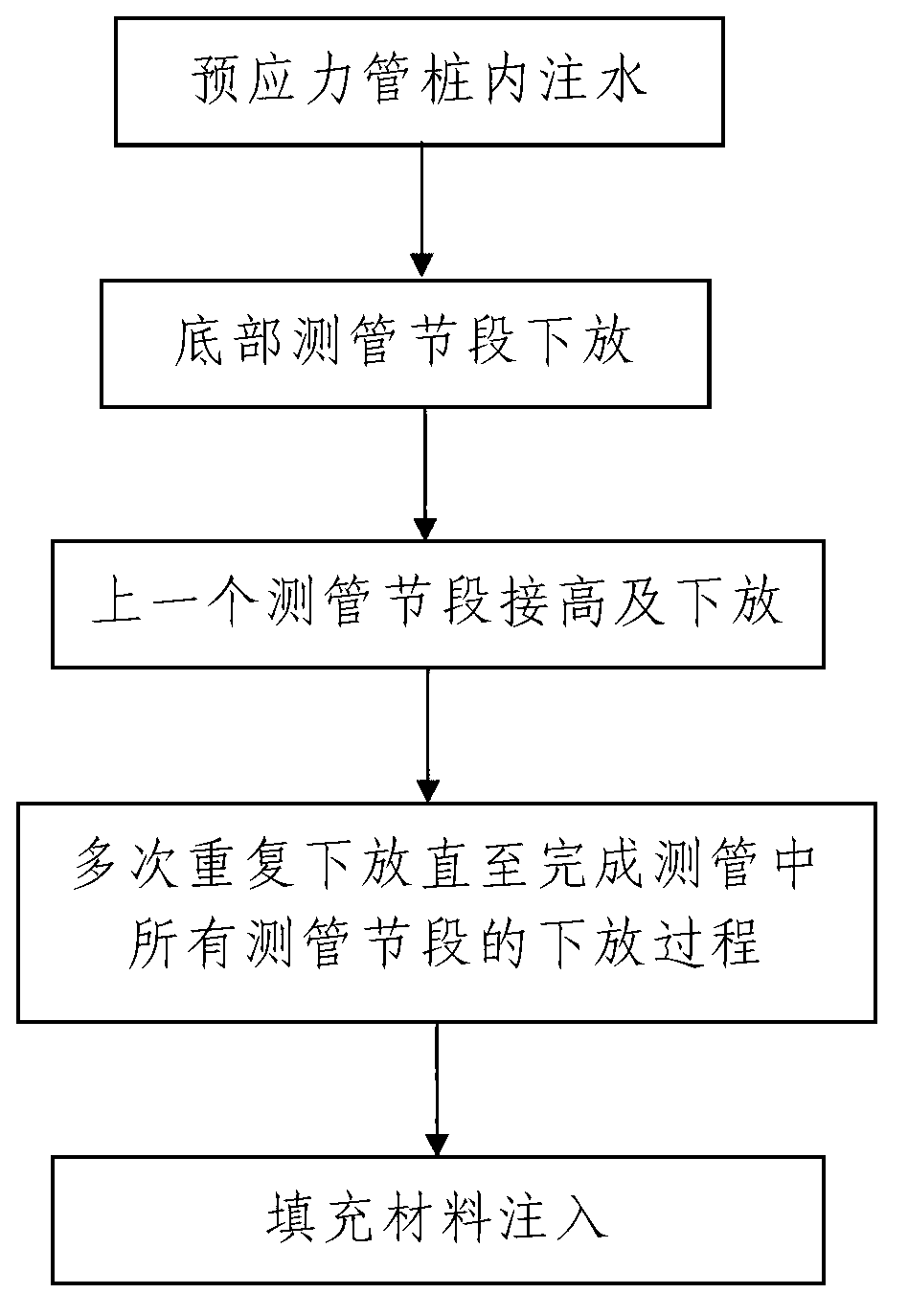

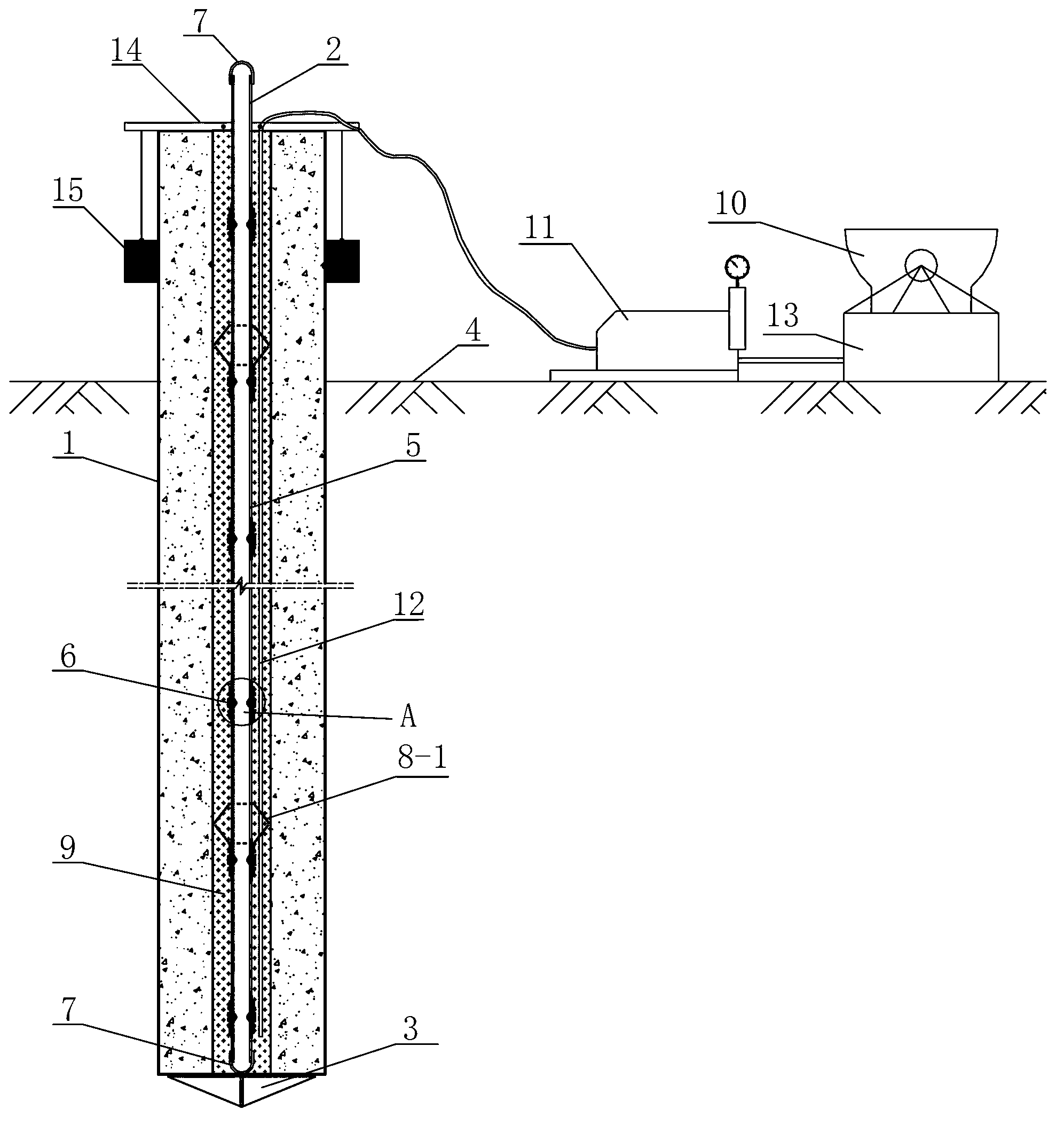

[0051] like figure 1 A method for installing a measuring tube for testing the internal force of a prestressed pipe pile with a sliding micrometer includes the following steps:

[0052] Step 1. Water injection into the prestressed pipe pile: After the construction of the prestressed pipe pile 1 is completed, the pipe pile core of the prestressed pipe pile 1 is filled with water.

[0053] The bottom of the prestressed pipe pile 1 is sealed and welded with a steel pile point 3, and the bottom of the pipe pile core is sealed by the steel pile point 3 to form a water storage chamber with an upper opening. The structure of the completed prestressed pipe pile 1 is See details figure 2 .

[0054] After the construction of the prestressed pipe pile 1 is completed, the height of the pile head reserved above the ground 4 of the prestressed pipe pile 1 is h=d3+d4+△, where d3 is the measurement mark on the top and the adjacent measurement point below it 6, d4 is the outer diameter of t...

Embodiment 2

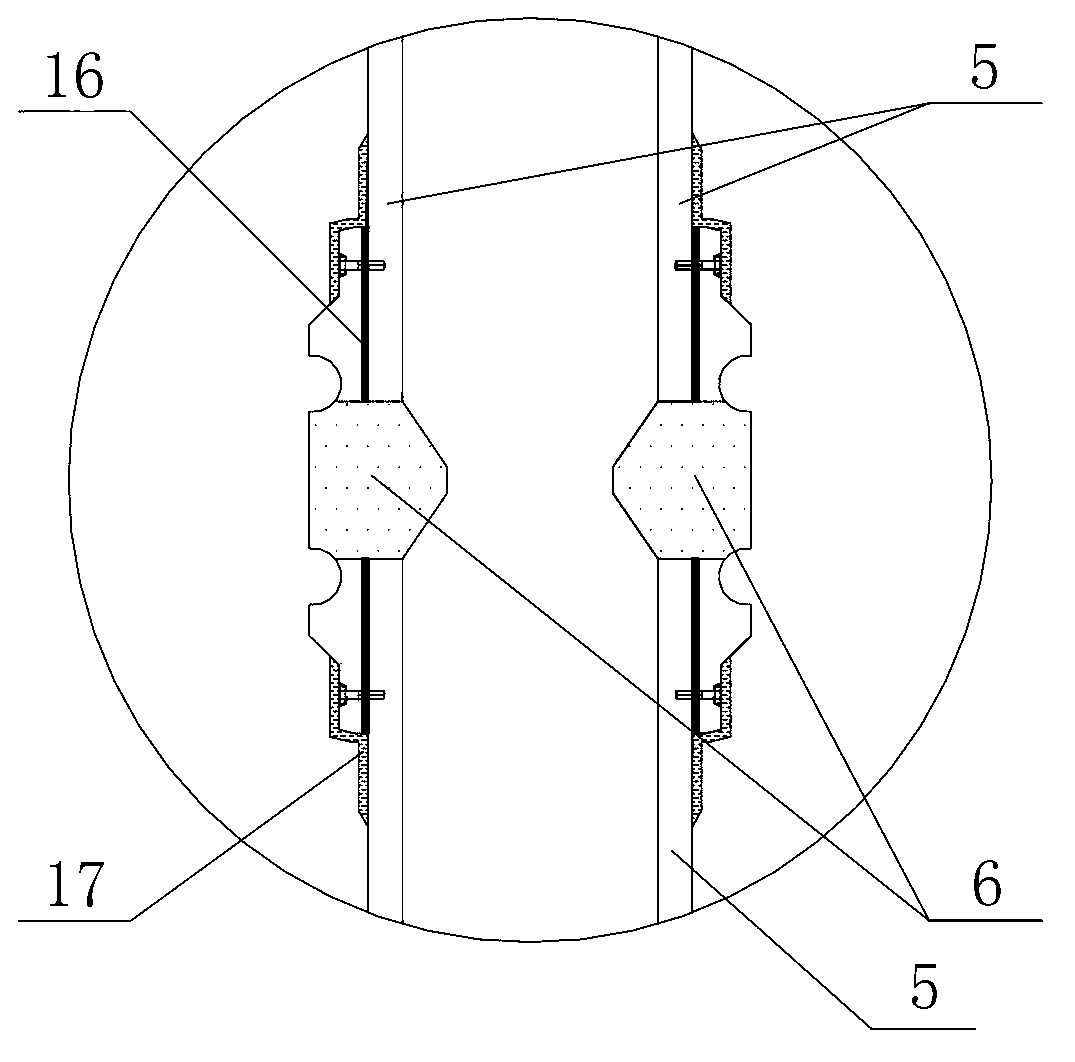

[0095] like Image 6 As shown, in this embodiment, the difference from Embodiment 1 is: the inner diameter of the prestressed pipe pile 1 described in step 1 is greater than Φ600m; the number of measuring tubes 2 described in step 2 is multiple, and the multiple The structure and size of the measuring tubes 2 are the same; when installing the measuring tubes in step 2, multiple measuring tubes 2 are installed synchronously, and the installation progress of the multiple measuring tubes 2 is the same; The installation methods of the pipes 2 are all the same, and are all installed according to the method described in step 201 to step 203.

[0096] At the same time, in step 2, a plurality of measuring tubes 2 are evenly arranged along the circumferential direction. combine Figure 7 , Figure 8 and Figure 9, in order to ensure the accuracy of the installation positions of the plurality of measuring tubes 2, the plurality of measuring tubes 2 are assembled as a whole through a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com