A method for installing a marine cargo tank

An installation method and a marine technology, which are applied in the direction of preventing the multi-way movement of goods, for bulk goods, etc., can solve the problem of poor fit between the tank bottom and the bilge plane, the difficulty of the installation of marine cargo tanks, and the impact on the strength of the ship. Safety and other issues, to achieve the effect of high fit, easy precise positioning, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

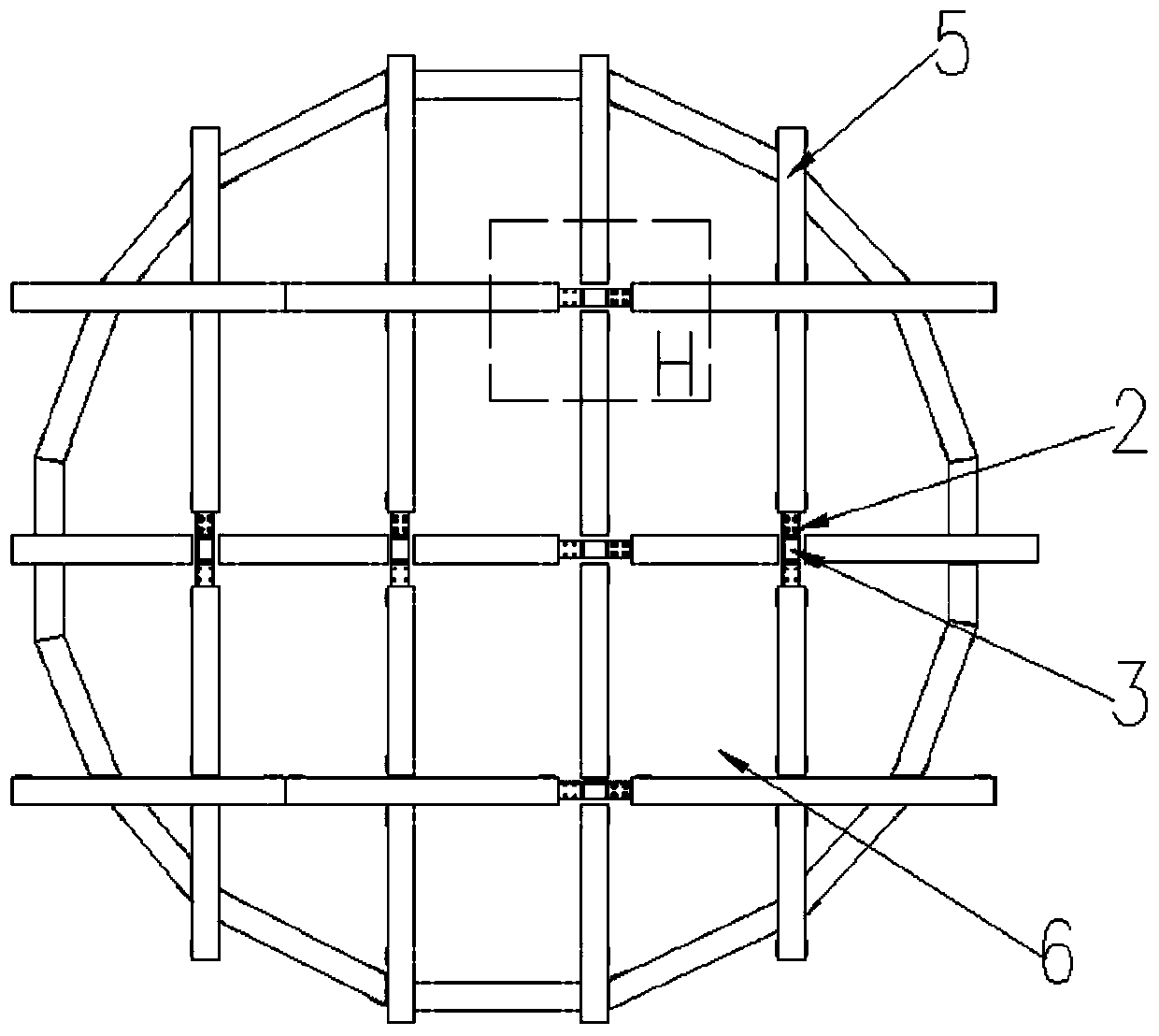

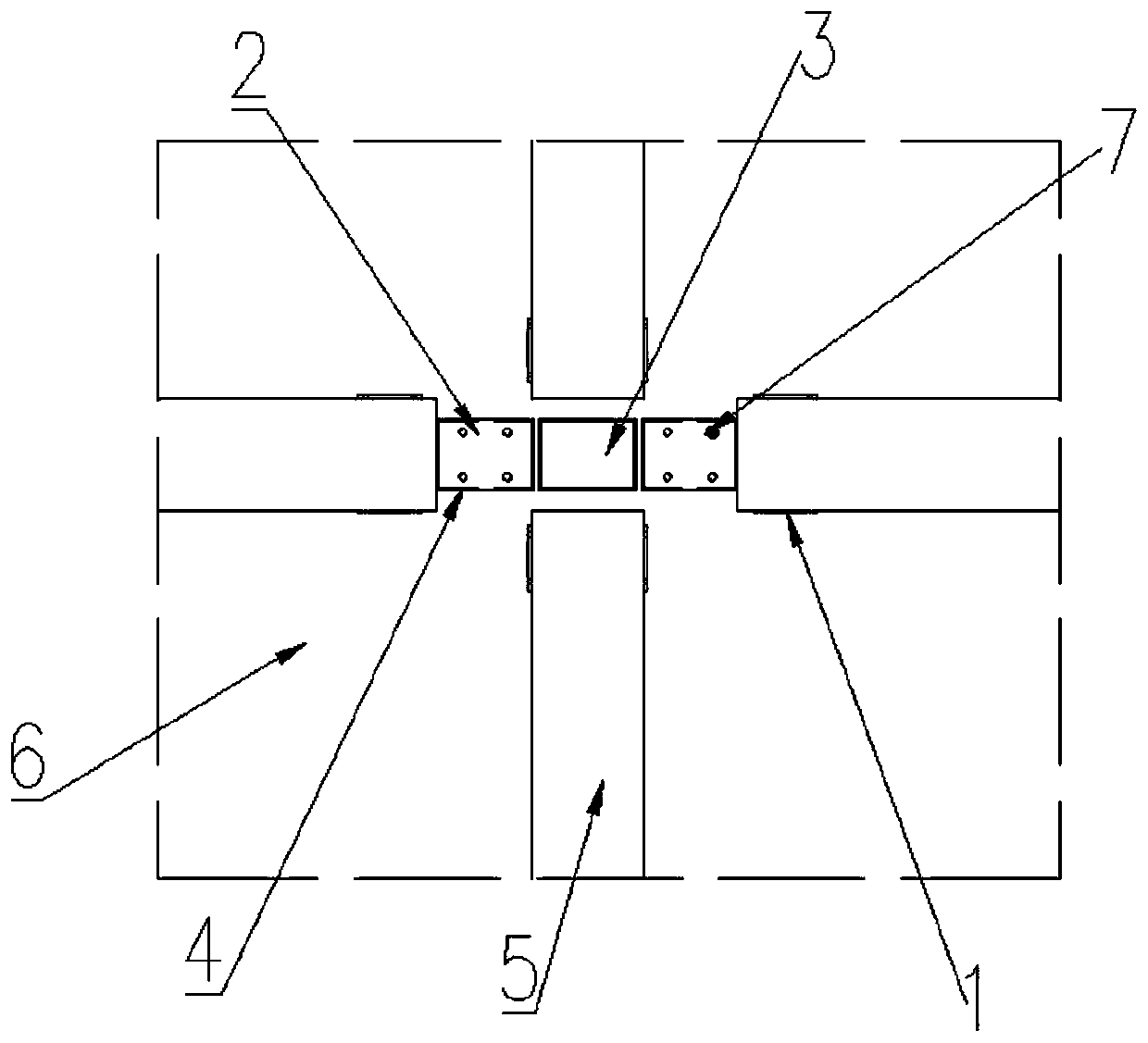

[0031] Such as Figure 1~3 Shown, the present invention is a kind of installation method of marine cargo tank, comprises the following steps:

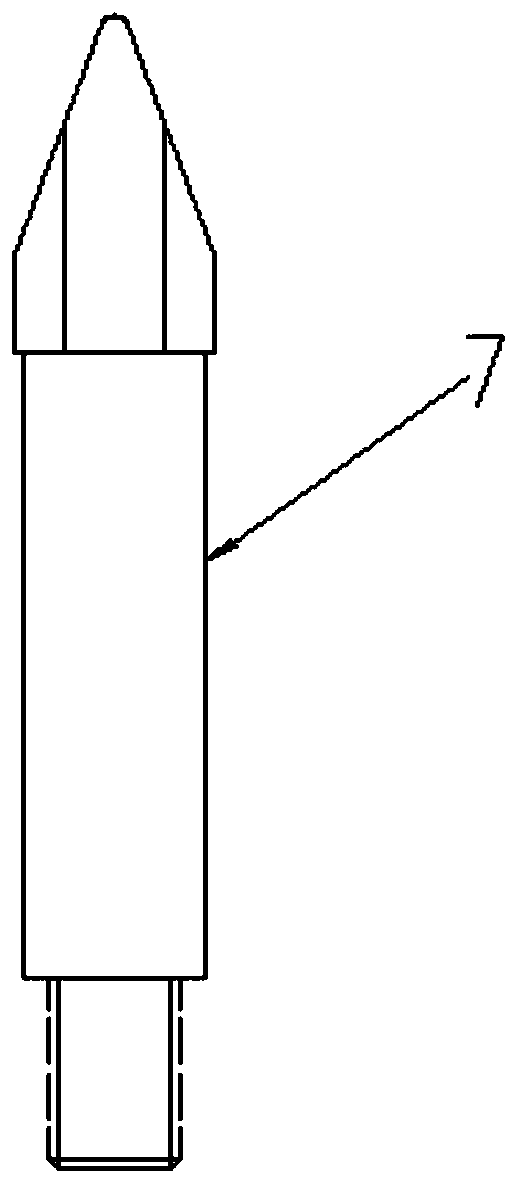

[0032]S1: Independent cargo tank design, install the base at the bottom of the independent cargo tank, install arrayed ribs on the lower end of the base, install horizontal flanges on both sides of the lower end of the ribs, and install horizontal flanges at the intersection of the ribs A downward projection is also installed, a number of installation holes are also arranged on the horizontal flange of the rib connected with the projection, a number of manholes are arranged on the peripheral surface of the base, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com