Combined circular chamfer wood formwork and manufacture method thereof

A technology of round chamfering and wood formwork, which is applied to the field of combined round chamfering wood formwork and its production, can solve the problems of low universality and reuse rate of formwork, large number of processed overall steel forms, and increased construction cost, etc. Achieving the effect of various specifications, many use turnover times and low construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

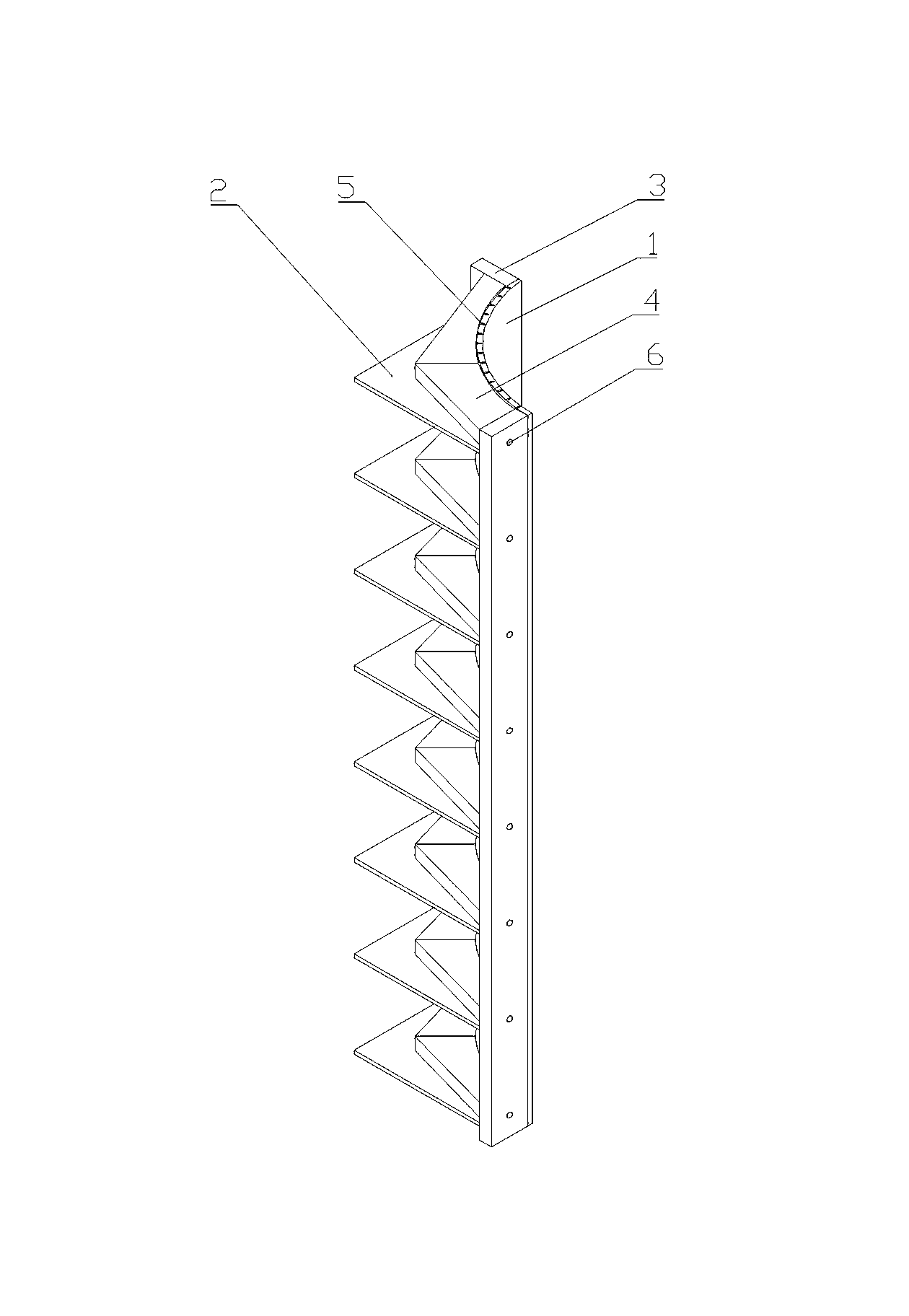

[0013] Such as figure 1 Shown, the present invention comprises the bamboo glue panel 1 that is circular arc shape outwards, is arranged on the connecting plate 2 of described bamboo glue panel 1 two ends, is arranged on the back side that described bamboo glue panel 1 protrudes and connects with described connecting plate 2 connected several wood glue positioning boards 3 and back ribs 4, the back ribs 4 are fixedly connected with the wood glue positioning boards 3, and the back ribs 4 are composed of two identical and symmetrically arranged square woods Compared with the existing technology, it is beneficial to save energy because it replaces the use of steel. The important thing is that this combined formwork is flexible in production, with various specifications and manufacturing. At the same time, the formwork is low in cost, not easy to corrode, and easy to use. Many times.

[0014] The combined round chamfering template is made according to the following steps:

[0015...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com