Arrangement method for precracking roof for roof-cutting roadway

A layout method and technology for cutting roof lanes, which are applied in the directions of safety devices, earthwork drilling, temporary shields, etc., can solve the problems of safety hazards, disasters, gas explosions, etc. in deep hole blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

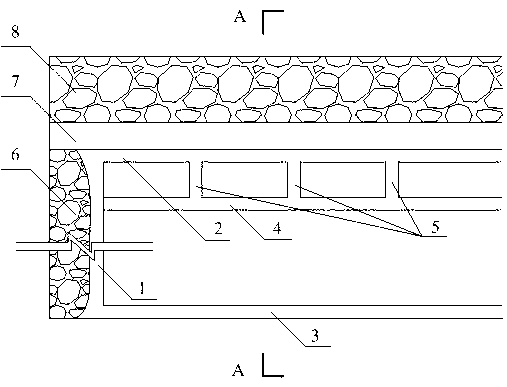

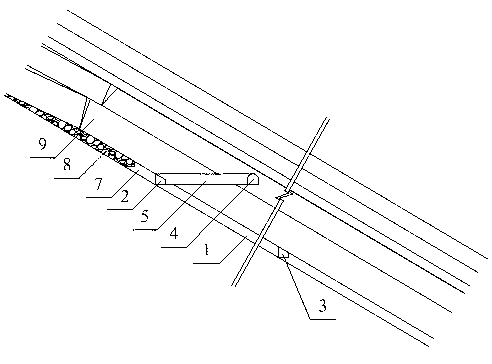

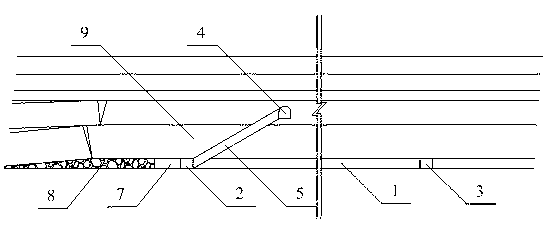

[0016] figure 1 figure 2 As shown, in the method for arranging the pre-split roof of the roof cutting roadway of the present invention, after the goaf 8 is formed by section mining on the coal mining face, the upper trough 2 and the lower trough 3 of the working face 1 are excavated. After 1 is formed, the high gas extraction roadway 4 located in or above the hard and thick roof 9 is constructed above the working face 1 on one side of the goaf 8 on the adjacent face. ~25m; In the area where pre-cracking and weakening of the roof is required, the roof cutting lane 5 connecting the upper channel 2 and the high gas pumping lane 4 is constructed. The length of the roof cutting lane 5 is 15~40m; the roof cutting lane 5 can be constructed as a semicircle Arched, can also be constructed as a square roadway. When the mining of working face 1 advances, the susp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com