Roof-cutting pressure relief method in hard-roof deep-hole pre-splitting blasting

A technology of pre-splitting blasting and top-cutting pressure relief, which is applied in the field of blasting pressure relief, can solve the problems of coal pillar stress concentration and strong mine pressure along the goaf roadway, reduce the deformation and damage of the roadway, and improve the stability of the coal pillar , the effect of wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

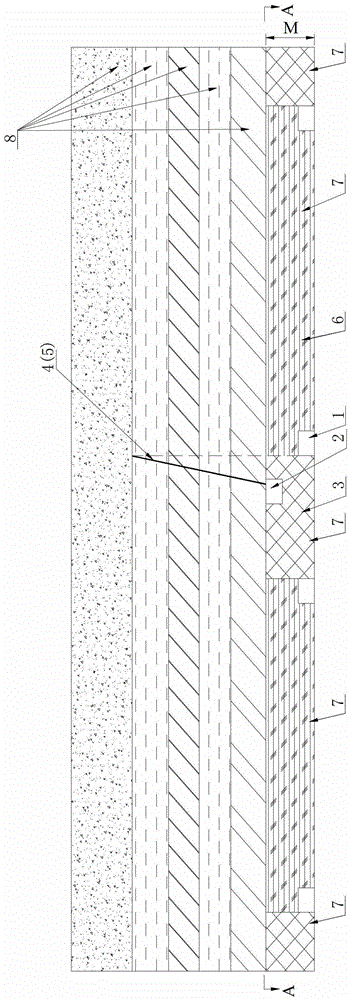

[0029] like Figure 1 to Figure 3 As shown, the thickness M of the coal seam in this embodiment is 10m, which specifically includes the following steps:

[0030] Step 1: Arrange the roof cutting roadway 2

[0031] The coal seam 7 is a very thick coal seam 7, so before the mining of the working face 6, the roof cutting roadway 2 is excavated along the roof of the coal seam 7 in the coal pillar 3, and the horizontal offset distance S between the roof cutting roadway and the mining roadway is 7m ;

[0032] Step 2: Arrange blast hole 4 and control hole 5

[0033] The inclined blasting hole 4 and the control hole 5 are longitudinally arranged in the roof rock layer 8 above the entire roof cutting roadway 2, and the control hole 5 is arranged in the middle position between the adjacent blasting holes 4; The distance of the roadway of the roof cutting roadway 2 close to the working face 6 is 1.5m, the bottom of the hole is set in the vertical plane of the roadway of the mining roa...

Embodiment 2

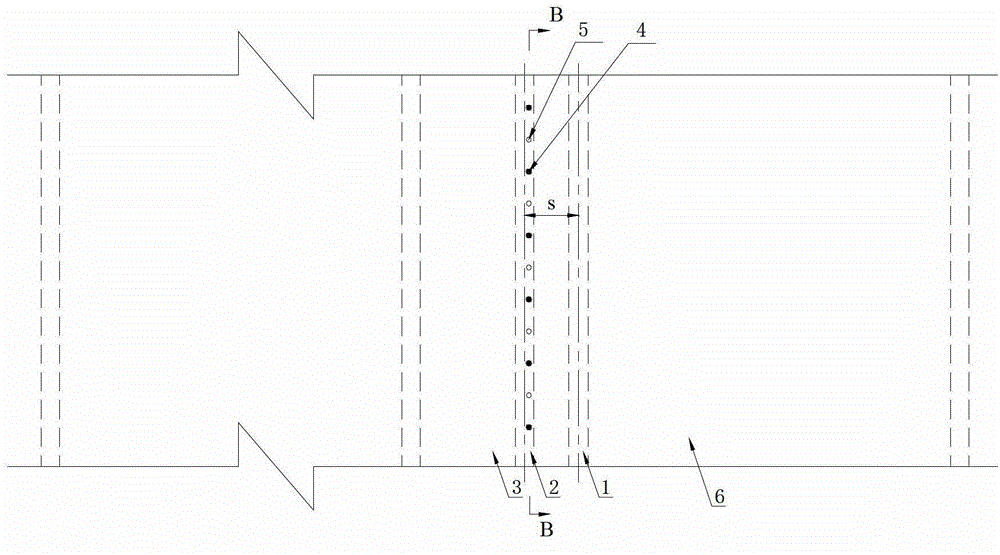

[0037] like Figure 4 to Figure 5 As shown, the thickness M of the coal seam in this embodiment is 5m, which specifically includes the following steps:

[0038] Step 1: Arrange the roof cutting roadway 2

[0039] The coal seam 7 is a thick coal seam 7, and the mining roadway 1 is used as the roof cutting roadway 2;

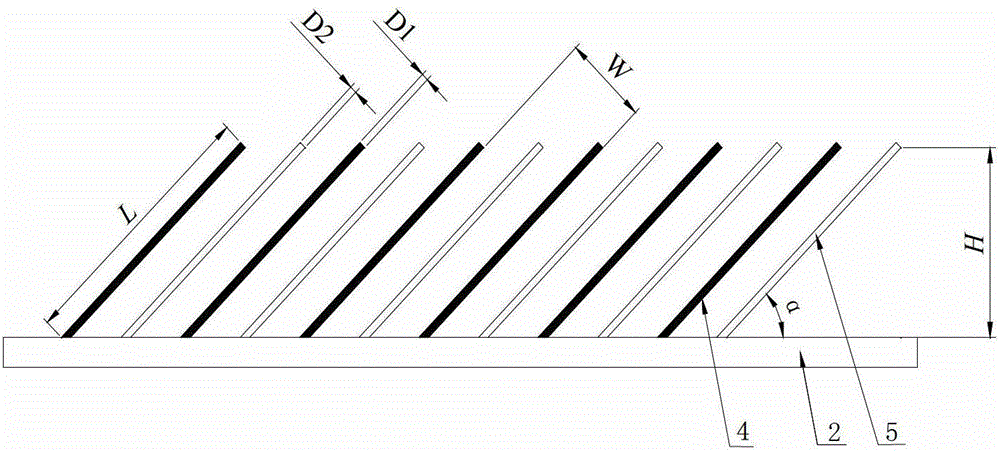

[0040] Step 2: Arrange blast hole 4 and control hole 5

[0041] The coal seam 7 and the roof rock layer 8 above the entire roof cutting roadway 2 are longitudinally provided with inclined blasting holes 4 and control holes 5, and the control holes 5 are arranged in the middle position between adjacent blasting holes 4; blasting holes 4 and control holes The distance between 5 and the roof cutting roadway 2 near the coal pillar 3 is 1.5m, the blasting hole 4 and the control hole 5 are arranged in parallel in the same vertical plane, and the included angle α between the blasting hole (control hole) and the coal seam roof is 45° , the distance W between adjacent b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com