Backlight module

A technology of backlight module and LED backlight, which is applied in the field of backlight module, can solve the problems of light leakage, limited adhesive area, and easy floating of LED light strips, so as to enhance the positioning function and avoid uneven light projection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

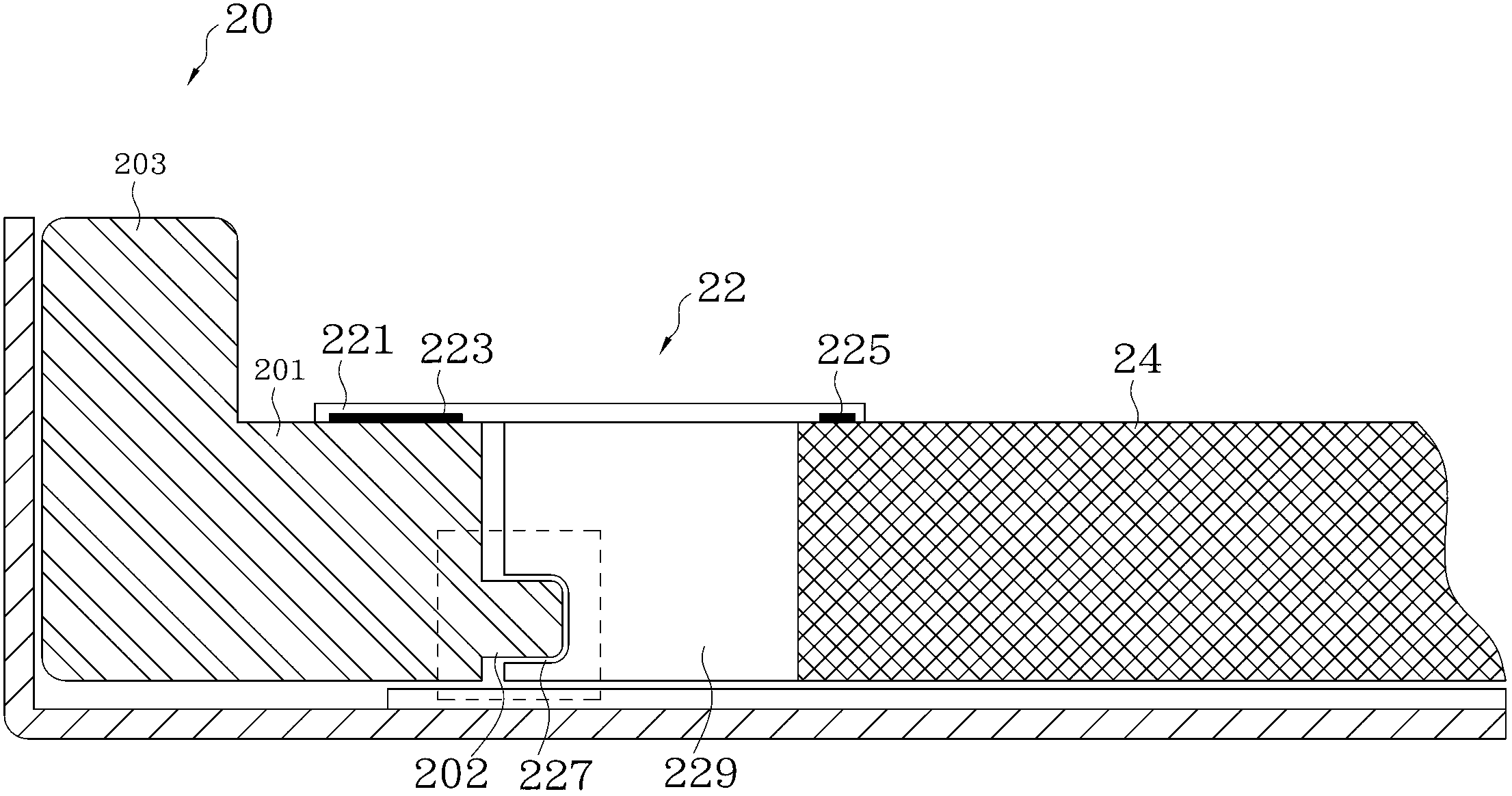

[0028] In order to make the technical content disclosed in this application more detailed and complete, reference may be made to the drawings and the following various specific embodiments of the present invention, and the same symbols in the drawings represent the same or similar components. However, those skilled in the art should understand that the examples provided below are not intended to limit the scope of the present invention. In addition, the drawings are only for schematic illustration and are not drawn according to their original scale.

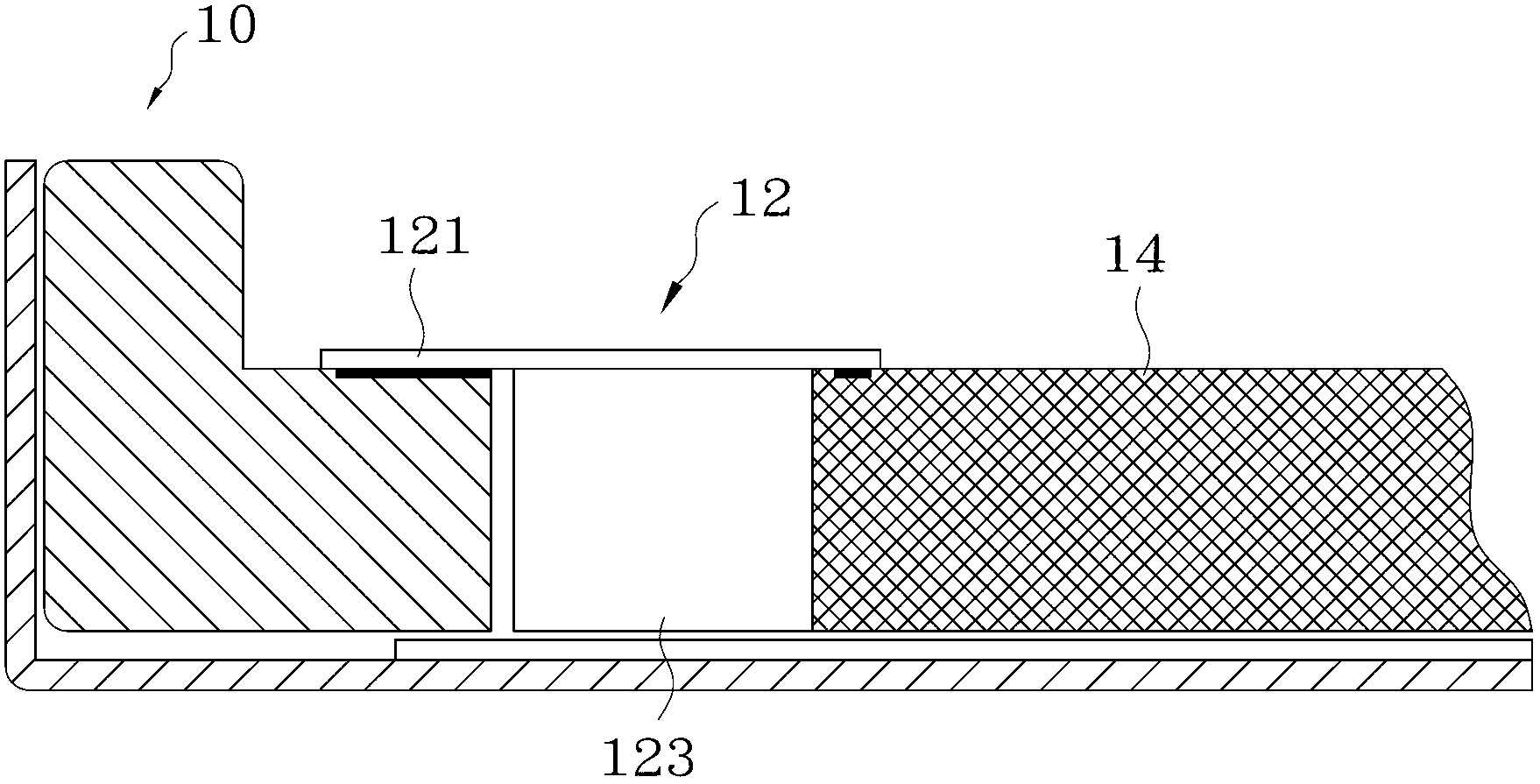

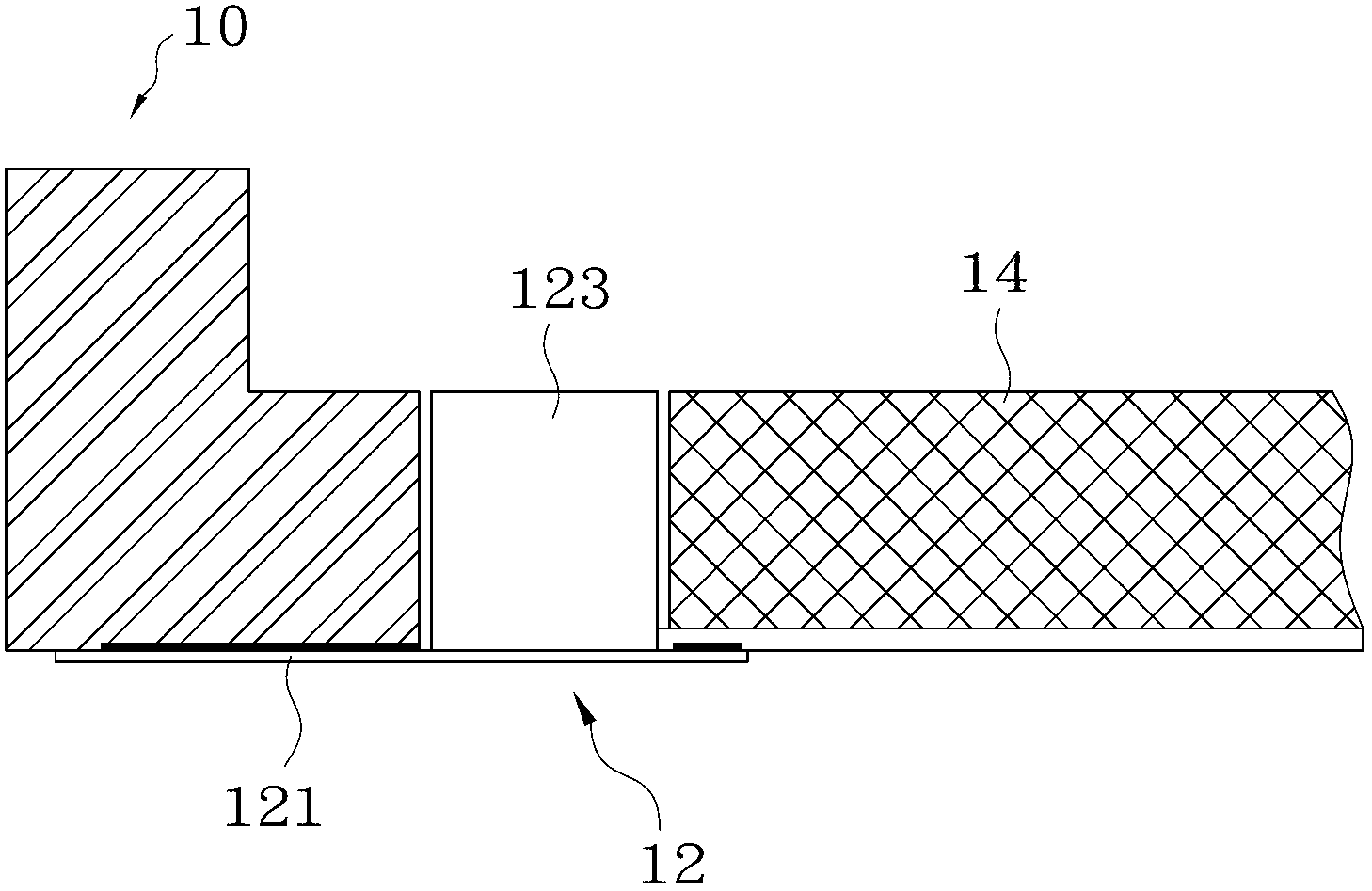

[0029] Figure 1A It is a schematic diagram showing the status of the LED in the traditional backlight module being limited by the way of snapping in from the front. refer to Figure 1A , the backlight module mainly includes a plastic frame 10 , an LED light bar 12 and a light guide plate 14 . Wherein, the LED light bar 12 includes a base plate 121 and an LED light 123 , the base plate 121 extends in the horizontal direction, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com