Mechanical arc-shaped workpiece polishing machine

A grinding machine and arc-shaped technology, which is applied in the field of mechanical parts processing, can solve the problems of no fixing mechanism, workpiece position movement, and poor fixing effect, so as to avoid workpiece position movement, improve grinding efficiency, and facilitate loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

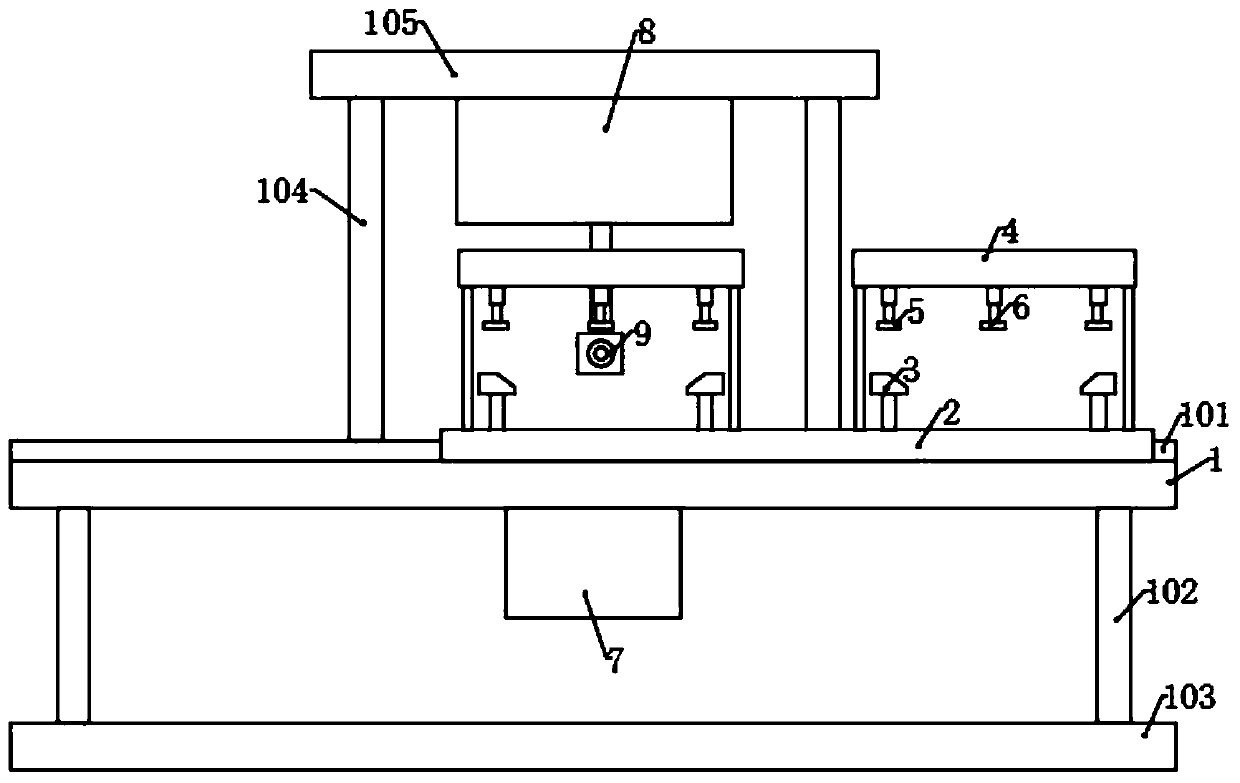

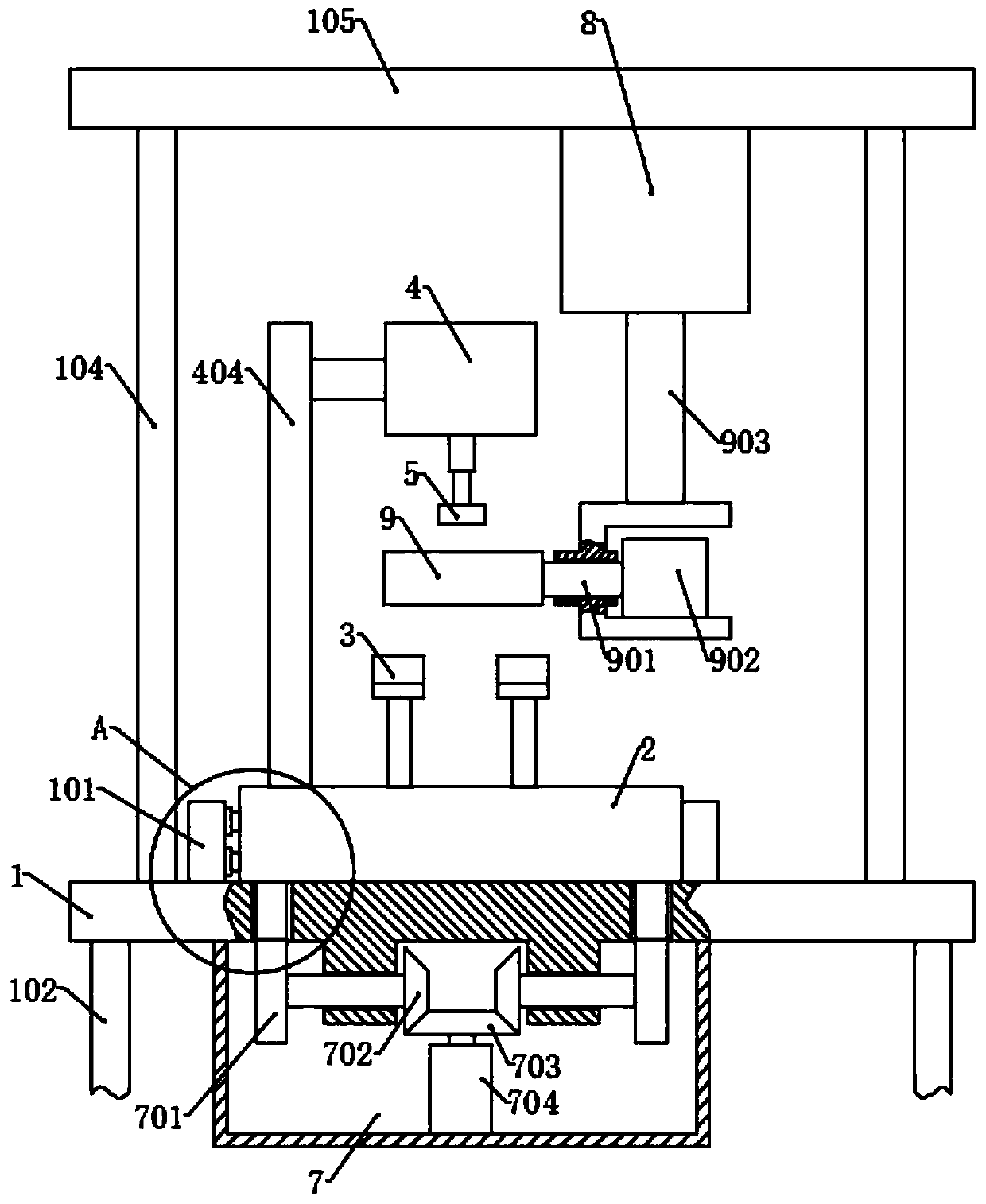

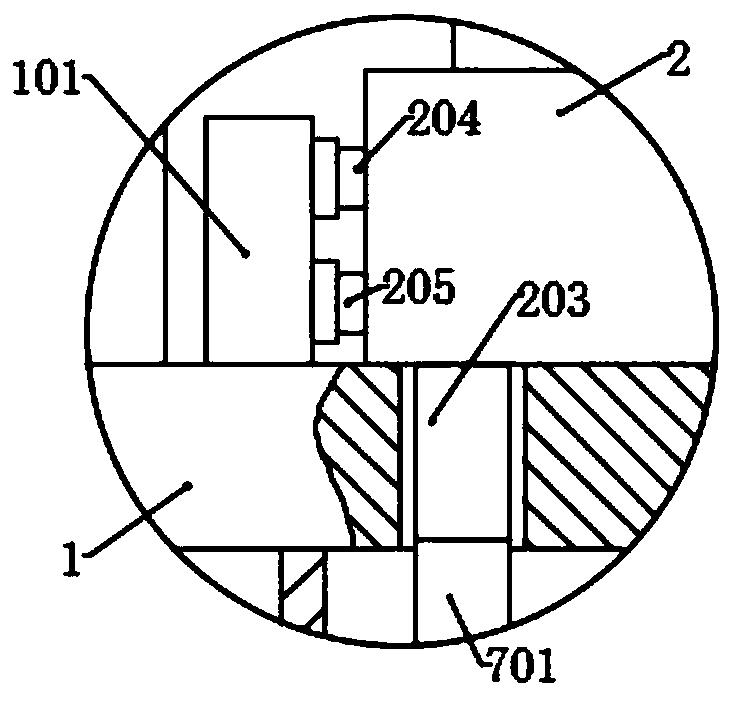

[0034] Please refer to the accompanying drawings, the present invention provides a technical solution: a mechanical arc-shaped workpiece grinding machine, including a workbench 1, a positioning mechanism, a drive box 7, an adjustment box 8 and a grinding assembly, and the four corners of the bottom surface of the workbench 1 are fixed There is a lower support rod 102, and a base 103 is fixed through the lower support rod 102. The drive box 7 is fixed in the middle of the bottom surface of the workbench 1, and the drive box 7 is provided with a driving mechanism, and the four corners of the top surface of the workbench 1 are fixed with upper Support rod 104, and is fixed with top plate 105 by upper support rod 104, and adjusting box 8 is fixedly connected with top plate 105, is provided with adjusting mechanism in adjusting box 8, and polishing assembly is connected with adjusting mechanism correspondingly, and the top surface of workbench 1 is also parallel Two limiting plates ...

Embodiment 2

[0042] On the basis of Embodiment 1, two sets of adjustment slots are provided on the positioning plate 2 corresponding to two sets of positioning blocks 3, each set of adjustment slots includes a drive slot 202, and two moving slots 201 are respectively provided on both sides of the drive slot 202, The bottom ends of the four positioning blocks 3 are located in the corresponding moving slots 201 and are fixed with the moving blocks. The first screw rods are threaded in the moving blocks, and the inner ends of the first screw rods are inserted into the driving slots 202 and fixed There is a first bevel gear, the first bevel gear meshes with a second bevel gear, and the second bevel gear is connected with a fourth motor.

[0043] The working principle of this embodiment is basically the same as that of Embodiment 1, the difference is that before placing the arc-shaped workpiece, according to the size of the arc-shaped workpiece, the first bevel gear and the second bevel gear are...

Embodiment 3

[0045] On the basis of Embodiment 2, a controller is also included, and the first motor 704, the second motor 902, the third motor and the fourth motor are all electrically connected to the controller, and the first motor 704 and the second motor 902 are controlled by the controller , the speed, direction of rotation, start time and shutdown time of the third motor and the fourth motor, reasonably arrange the working hours of each motor, etc., to avoid problems such as excessive working or stopping time of various components caused by manual control, and inaccurate control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com