a current transformer

A current transformer, part of the technology, applied in the direction of transformer/inductor core, inductor/transformer/magnet manufacturing, voltage/current isolation, etc. Achieve the effects of improving metering accuracy, reducing power leakage rate, and fair billing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

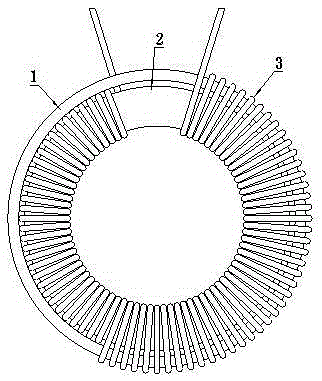

[0015] The present invention is a through-core current transformer without a primary winding, and its iron core is composed of two parts, the ultramicrocrystalline iron core 2 is the main iron core, and the silicon steel sheet compensation iron core 1 is set outside the ultramicrocrystalline iron core 2 . Part of the secondary winding 3 is wound on the ultramicrocrystalline iron core 2 , and the rest is wound on the ultramicrocrystalline iron core 2 and the silicon steel sheet compensation iron core 1 .

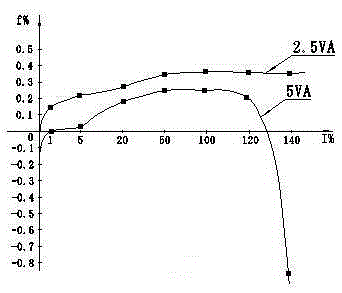

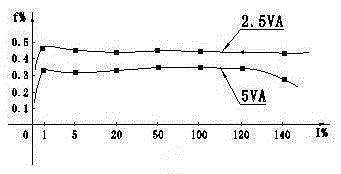

[0016] Compared with the traditional one: the traditional 150 / 5 ultra-amorphous current mutual inductance, the iron core weighs 270 grams, and 29.8 turns are wound with 2 square enameled wires. The data obtained from the test are drawn as follows: figure 2 Shown; After improvement, use 240 grams of ultra-amorphous iron core as the main iron core, and 20 grams of ZH-130 silicon steel sheet as the compensation iron core, and the compensation iron core is 8.5% of the main iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com