Electric operation mechanism of switch

A technology of electric operating mechanism and manual operation, applied to the power device inside the switch, etc., can solve the problems of low product safety and reliability, many parts, complicated mechanism, etc., and achieve the effect of safe and reliable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

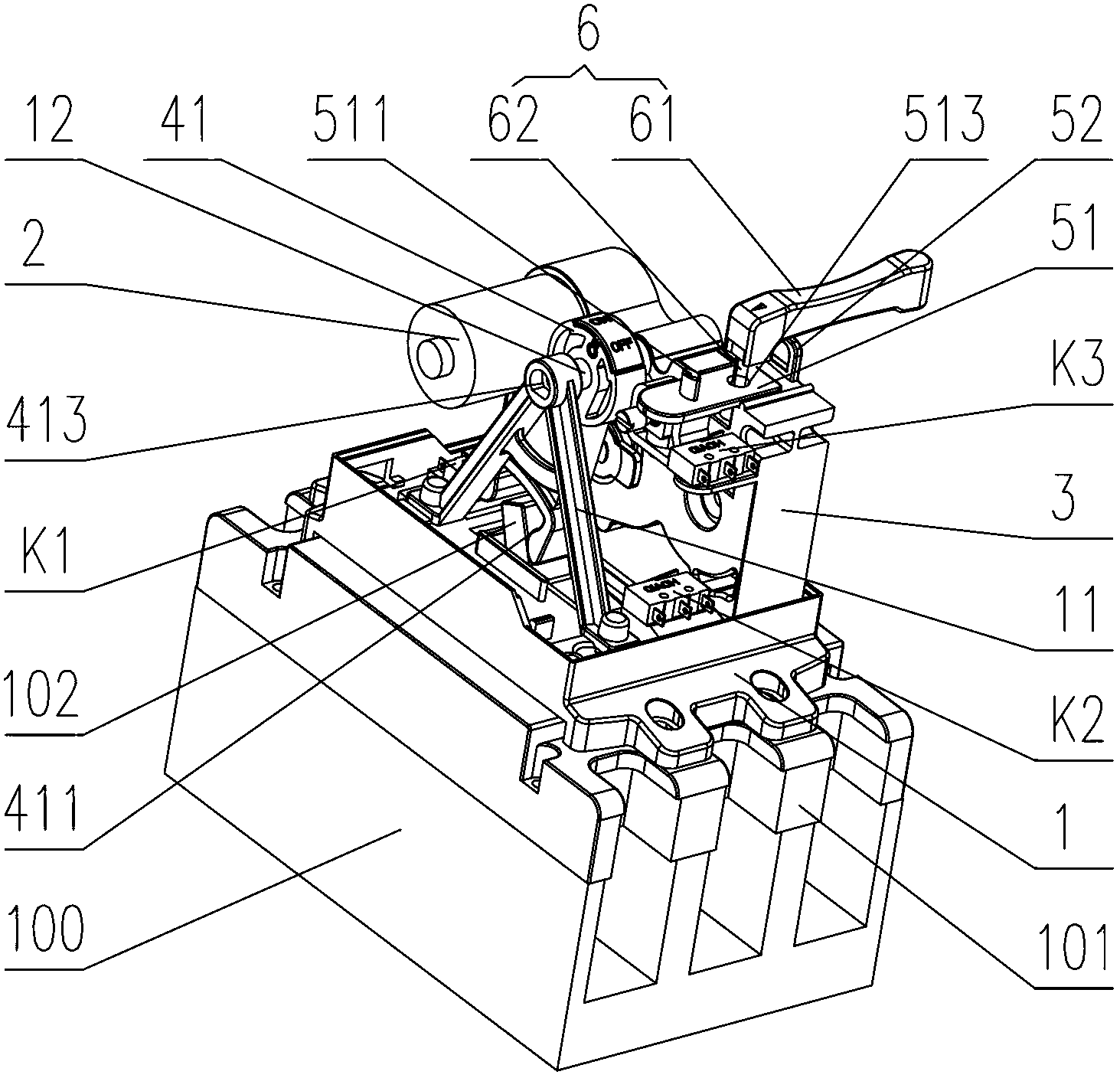

[0031] The implementation of the present invention will be described in detail below with reference to the accompanying drawings, and the electric operating mechanism of the switch of the present invention is not limited to the description of the following embodiments.

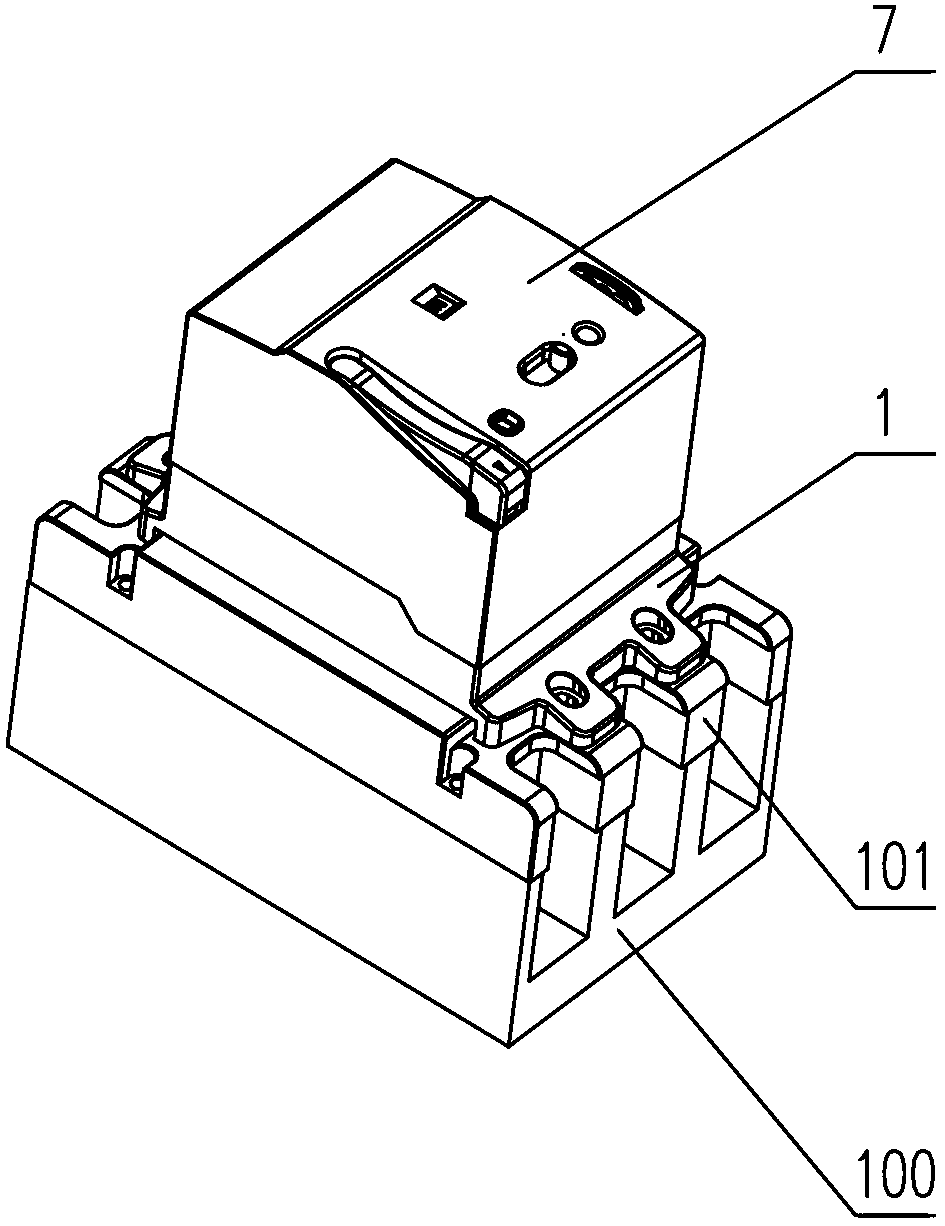

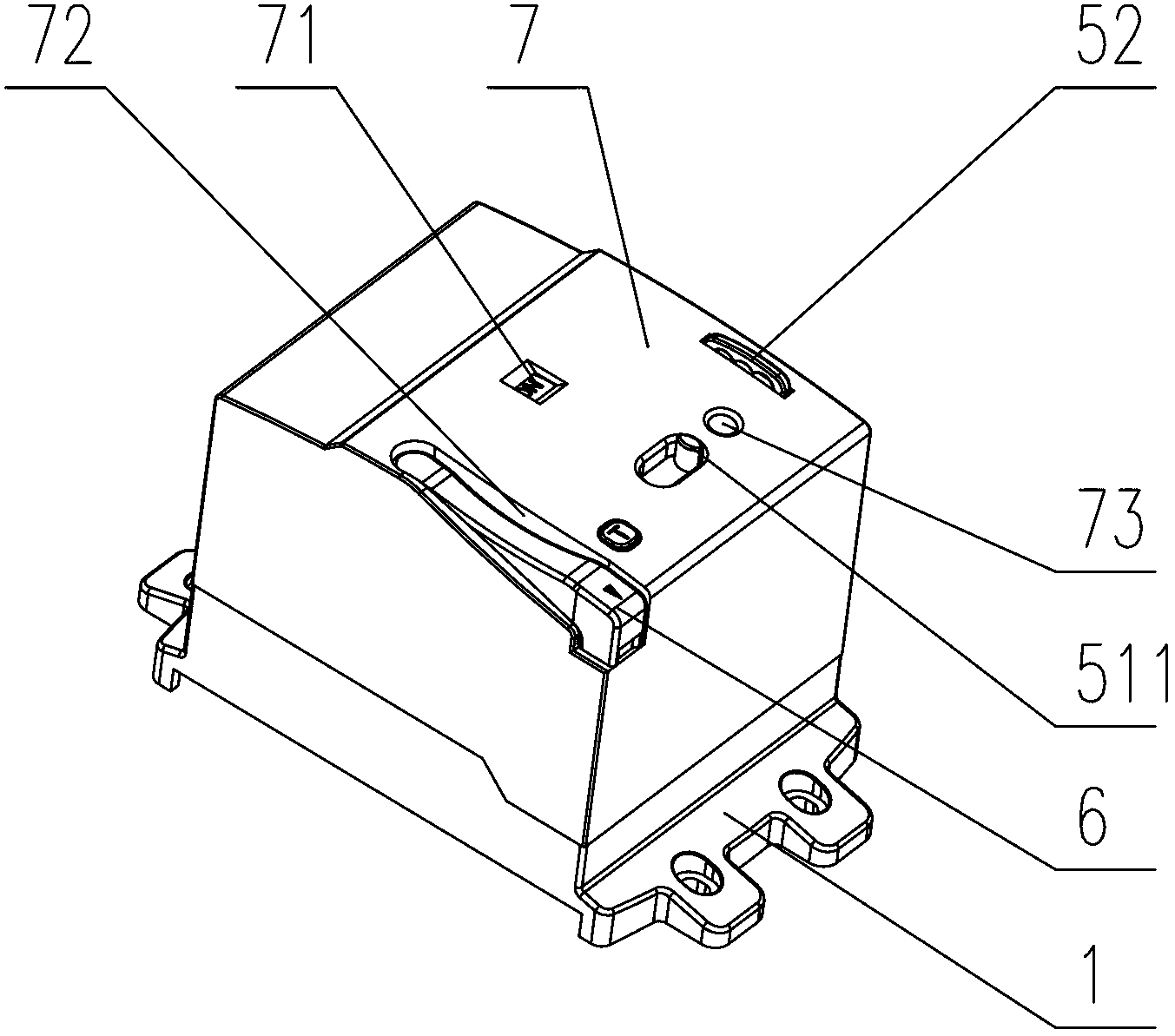

[0032] see Figure 1 to Figure 11 , the electric operating mechanism of the molded case circuit breaker and other isolating switches of the present invention includes a base 1 that can be fixedly installed on the panel 101 of the operated switch 100, and a motor 2, a reducer 3, a driving device 4, and a control device 5. Manual operation handle 6, control panel 7. It is well known that the installation method of the electric operating mechanism will affect the use, function and structural scheme of the electric operating mechanism product. The electric operating mechanism of the present invention adopts the installation method that the base 1 is fixedly connected with the panel 101 of the operated switch 100, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com