Semiconductor device and method of manufacturing the same

A semiconductor, conductive type technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve problems such as hFE being smaller than expected value, inability to obtain V-NPN transistor characteristics, etc., to achieve the effect of reasonable manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

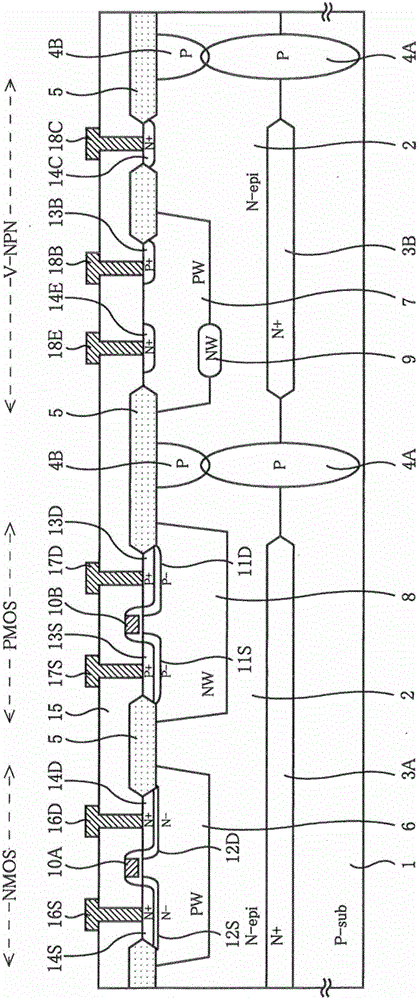

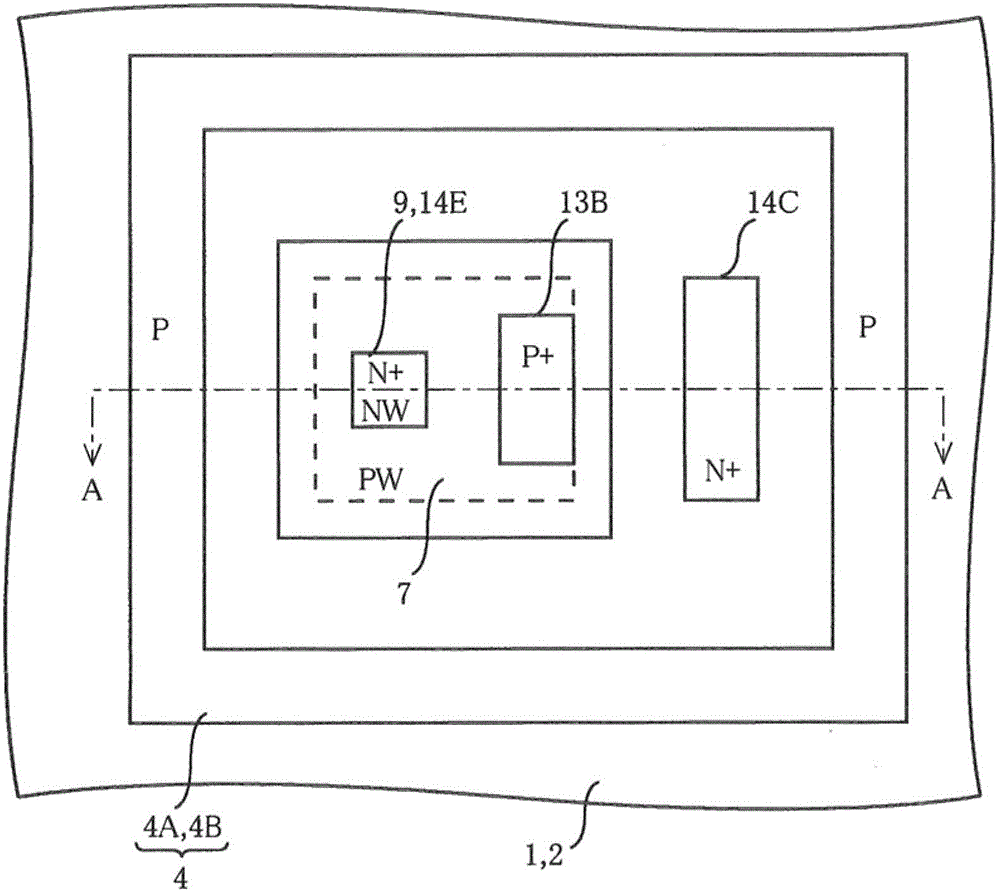

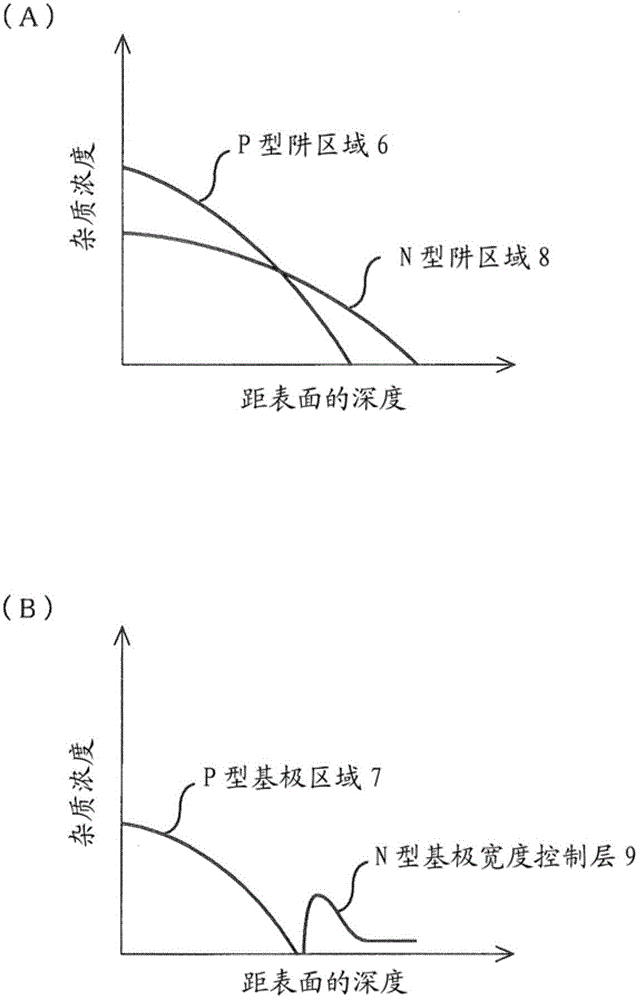

[0052] figure 1 It is a cross-sectional view of the semiconductor device according to the first embodiment of the present invention. figure 2 It is a top view of a V-NPN transistor of a semiconductor device. figure 2 The sectional view of the A-A line of figure 1 Corresponding to the cross-sectional view of the V-NPN transistor.

[0053] An N − -type epitaxial semiconductor layer 2 is formed on a semiconductor substrate 1 made of a P-type single crystal. The semiconductor substrate 1 and the N-type epitaxial semiconductor layer 2 form a PN junction. In the formation region of the NMOS transistor and the PMOS transistor, an N+ type buried layer 3A is formed across the PN junction of the semiconductor substrate 1 and the N-type epitaxial semiconductor layer 2, so as to reduce the N-type epitaxial semiconductor layer 2 (PMOS transistor) substrate) resistance.

[0054] In addition, in the formation region of the V-NPN transistor, an N+-type buried layer 3B is formed across ...

no. 2 approach 〕

[0081] Figure 4 It is a cross-sectional view of a semiconductor device according to a second embodiment of the present invention. This embodiment and the first embodiment ( figure 1 ) in that the N − -type emitter region 12E having a lower concentration than the N + -type emitter region 14E is formed in contact with the bottom of the N + -type emitter region 14E. In order to rationalize the process, the N + -type emitter region 14E is preferably formed using the process of forming the N + -type source layer 14S and the N + -type drain layer 14D of the NMOS transistor (ion implantation of N-type impurities). The N − -type emitter region 12E is preferably formed using the steps of forming the N − -type source layer 12S and the N − -type drain layer 12D of the NMOS transistor (ion implantation of N-type impurities).

[0082] The N-type source layer 12S and the N-type drain layer 12D of the NMOS transistor are formed deeper than the N+-type source layer 14S and the N+-type drai...

no. 3 approach 〕

[0087] Figure 5 is a cross-sectional view of a semiconductor device according to a third embodiment of the present invention. This embodiment and the second embodiment ( Figure 4 ) in that the P + -type base region 11B is formed in contact with the bottom of the N − -type emitter region 12E and has an increased concentration of the P-type base region 7 . In order to rationalize the process, the P+-type base region 11B is preferably formed using the process of forming the deep P-type source layer 11S and P-type drain layer 11D of the PMOS transistor (ion implantation of P-type impurities such as boron).

[0088] In order to form the P-type source layer 11S and the P-type drain layer 11D deeper than the P+-type source layer 13S and the P+-type drain layer 13D, for example, the P-type source layer 11S and the P-type drain layer 11D is formed by ion implantation of boron, and the P+ type source layer 13S and P+ type drain layer 13D are formed by ion implantation of boron diflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com