White-light LED (Light Emitting Diode) and packaging method thereof

A packaging method and white light technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of not enough soft color, poor color rendering, weak red spectrum of white LEDs, etc. The effect of color rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

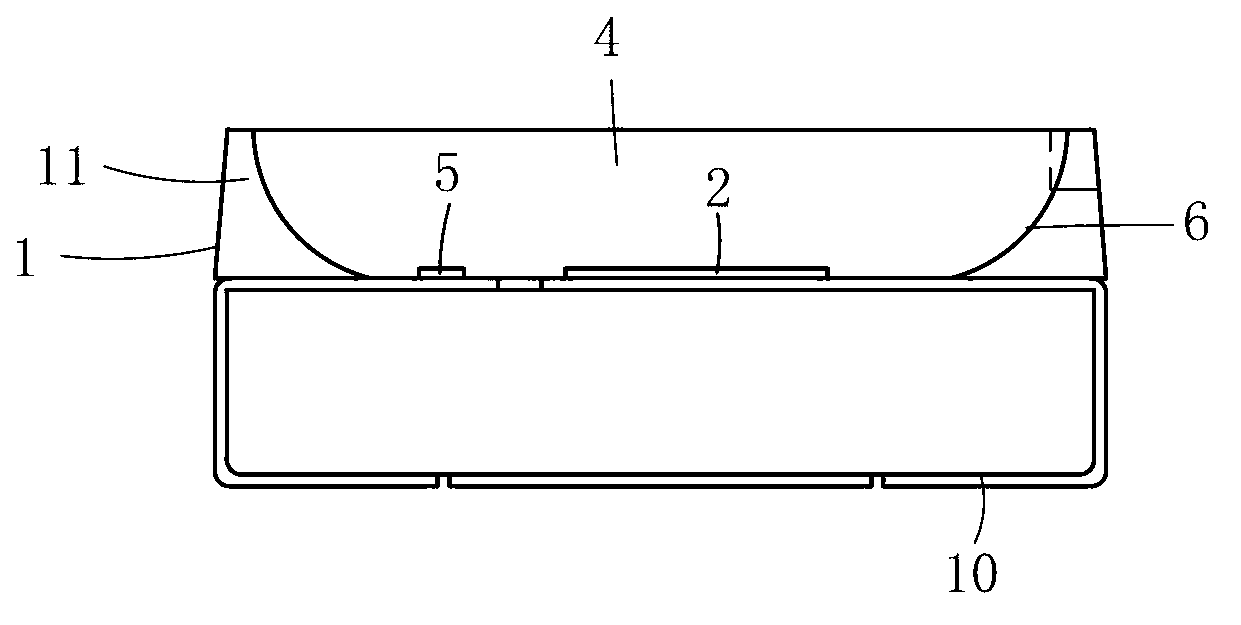

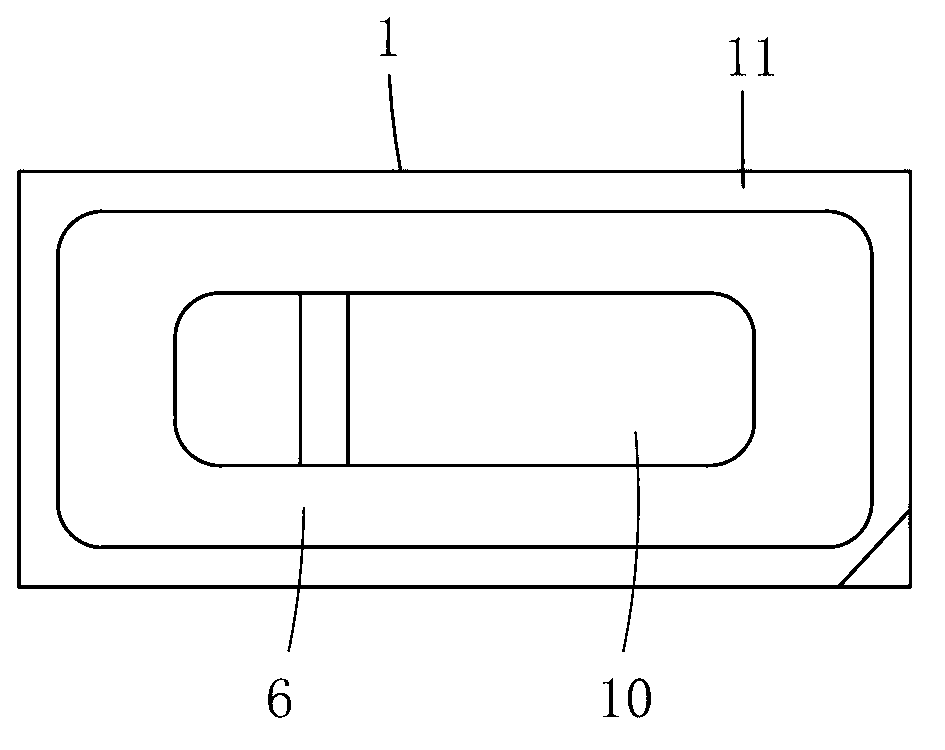

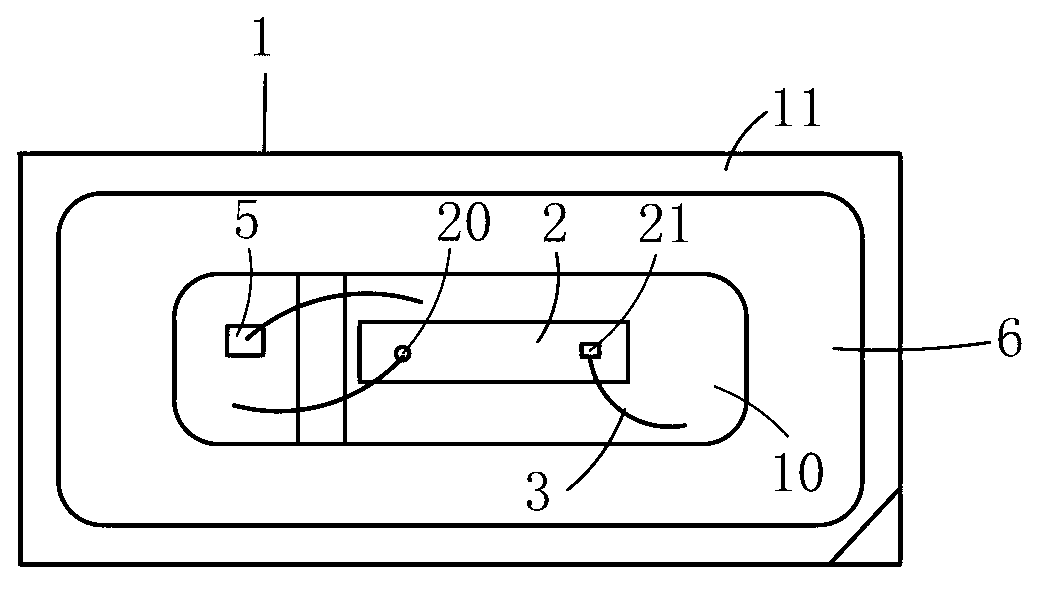

[0029] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Commonly shown, a white light LED, this white light LED is a SMD3014 lamp bead, including a bracket 1, a bracket electrode 10 is provided at the lower part of the bracket, a cooling cup 6 is fixed on the bracket electrode 10, and the bracket electrode 10 is the bottom of the cooling cup 6 A blue light chip 2 is provided on the bracket electrode 10 located at the bottom of the heat dissipation cup 6, and a wire 3 is connected between the blue light chip 2 and the bracket electrode 10, and the wire 3 is a gold wire; the inside of the heat dissipation cup 6 is coated with fluorescent glue 4, Fluorescent glue 4 is prepared from the following raw materials, nitride red phosphor R6733 (Intemet Optoelectronics (Shenzhen) Co., Ltd.): positive white phosphor Y4651 (Intemet Optoelectronics (Shenzhen) Co., Ltd.): green phosphor G3560 (Intemei Optoelectronics (Shenzhen) Co., Ltd.): Silicone 6551AB (Dow Corning 6551 ...

Embodiment 2

[0041] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5Commonly shown, a white light LED, its structure is basically the same as that of Example 1, the difference lies in the weight ratio of nitride red phosphor R6733, positive white phosphor Y4651, green phosphor G3560 and silica gel 6551AB in fluorescent glue 4 For: nitride red phosphor R6733: positive white phosphor Y4651: green phosphor G3560: silica gel 6551AB=X:Y:Z:1000, where X=4, Y=93, Z=3.

Embodiment 3

[0043] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Commonly shown, a white light LED, its structure is basically the same as that of Example 1, the difference lies in the weight ratio of nitride red phosphor R6733, positive white phosphor Y4651, green phosphor G3560 and silica gel 6551AB in fluorescent glue 4 For: nitride red phosphor R6733: positive white phosphor Y4651: green phosphor G 3560: silica gel 6551AB=X:Y:Z:1000, where X=7, Y=87, Z=6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com