Watercraft with stepped hull and outboard fins

A watercraft and wing technology, which is applied in the field of watercraft with graded hulls and outboard wings, can solve the problems of complicated combination of internal piping systems and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

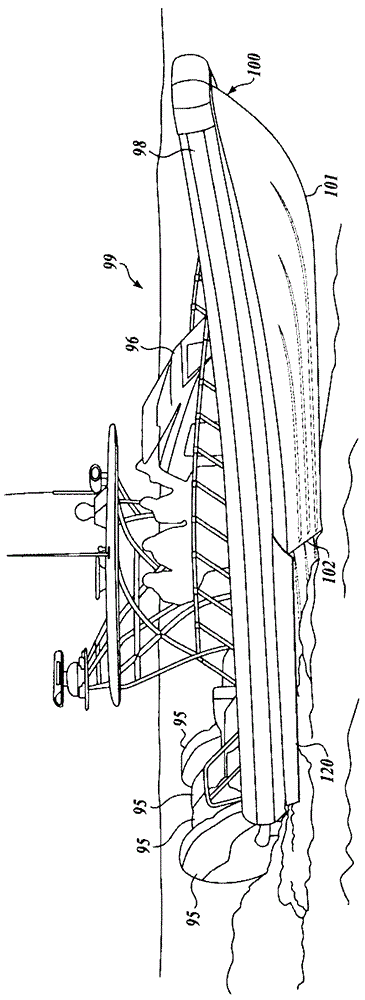

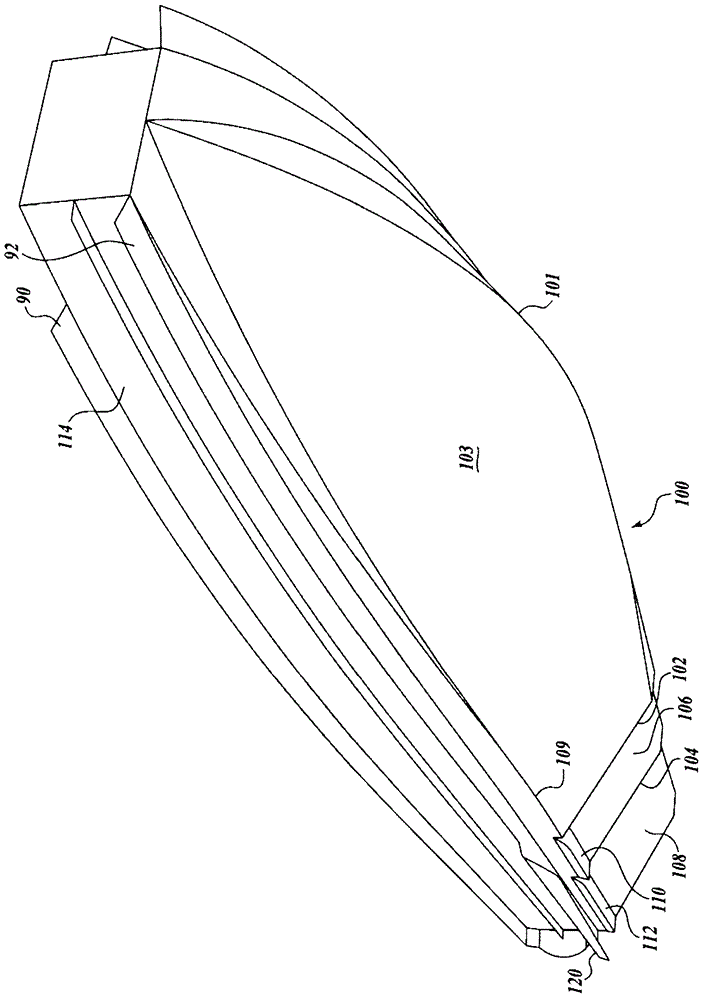

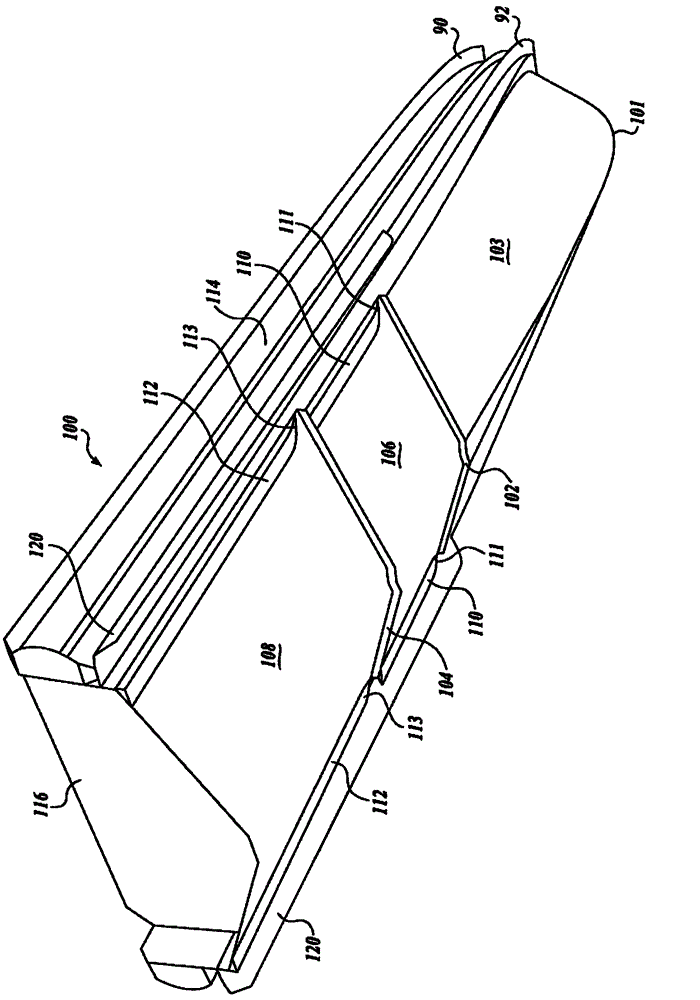

[0019] exist figure 1 A high performance watercraft 99 according to the invention is shown operating at planing speed. The watercraft 99 includes a step planing hull 100 having oppositely disposed ports and an outboard performance wing, referred to herein as a ram air wing 120 , at the aft end of the hull 100 partly on. The ram air wings 120 extend longitudinally along the stepped portion of the hull 100 . This exemplary embodiment generally corresponds to the Apostle™ series of high performance watercraft manufactured by SAFEBoats International L.L.C. (www.safeboats.com), but those skilled in the art can apply the invention to a variety of watercraft.

[0020] In the current embodiment, the hull 100 is formed primarily of aluminum and may be, for example, from 29 feet to 42 feet in length. Other hull sizes are also conceivable. Optional foam gangways 98 are shown disposed about the upper perimeter of the hull 100 . A console 96 with operator controls is located approxima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com