Lens cutting apparatus

A cutting device and lens technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of difficult control of special lotion concentration, decreased product yield, and residual glue, etc., to avoid the problem of colloid residue. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

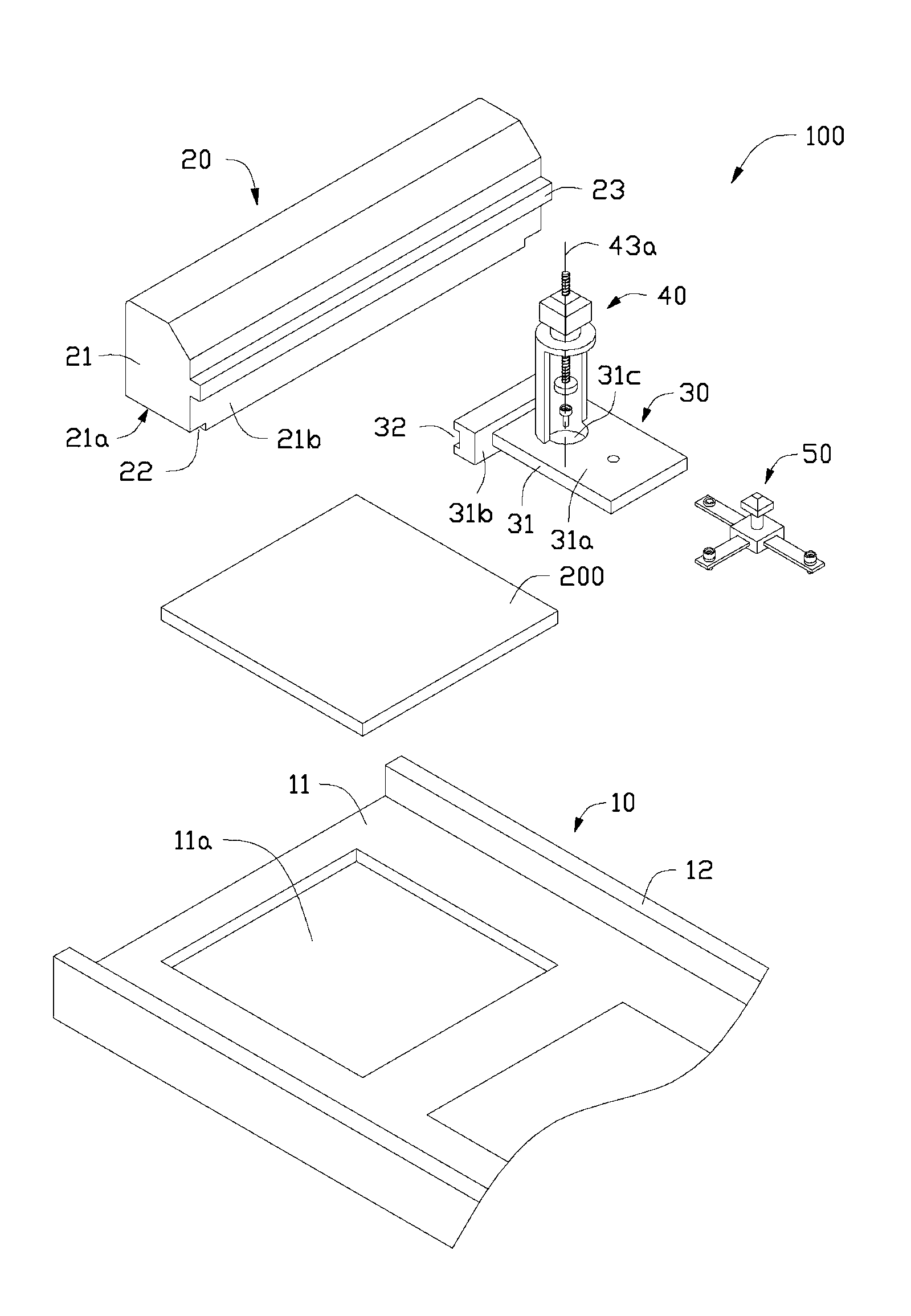

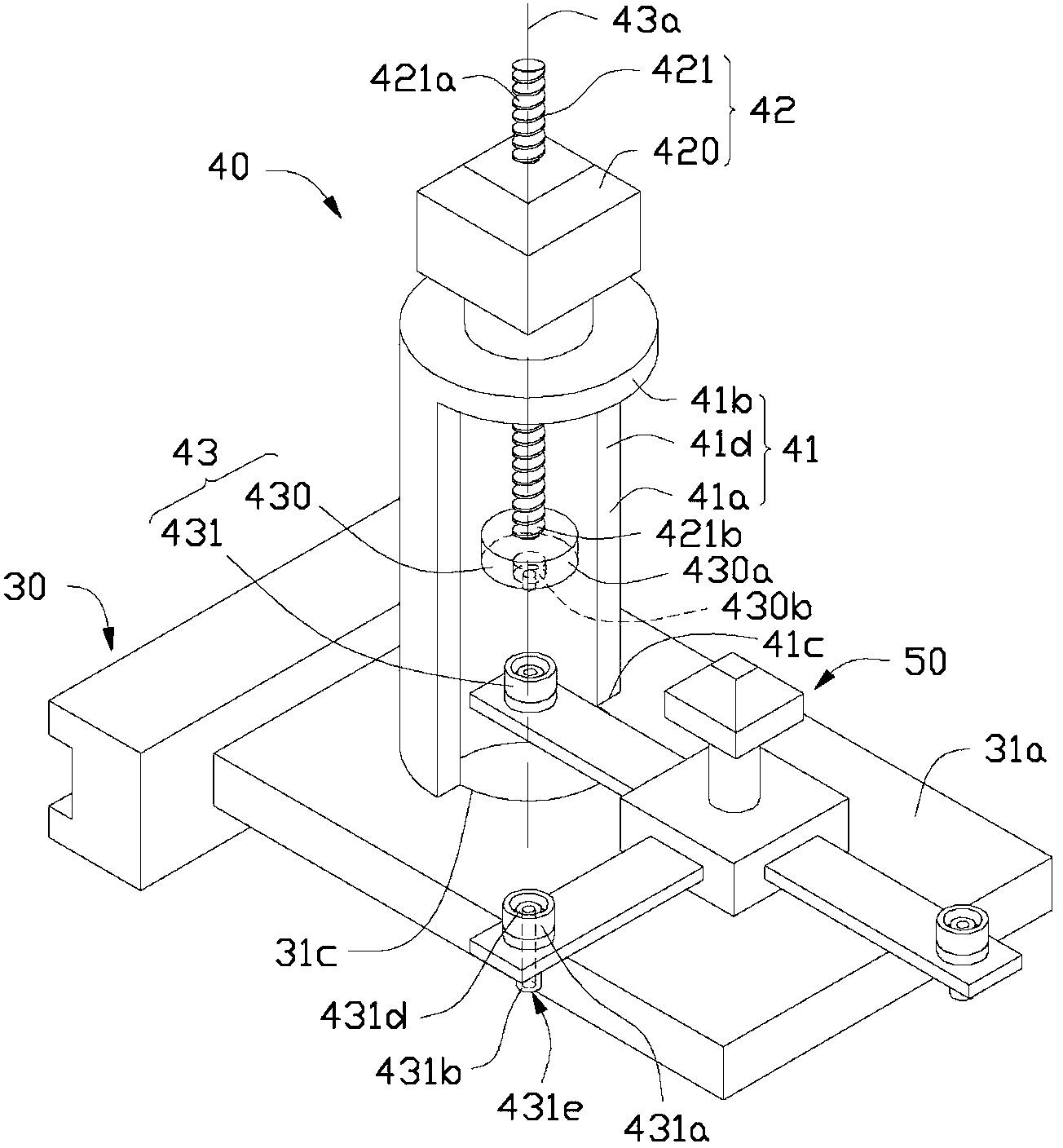

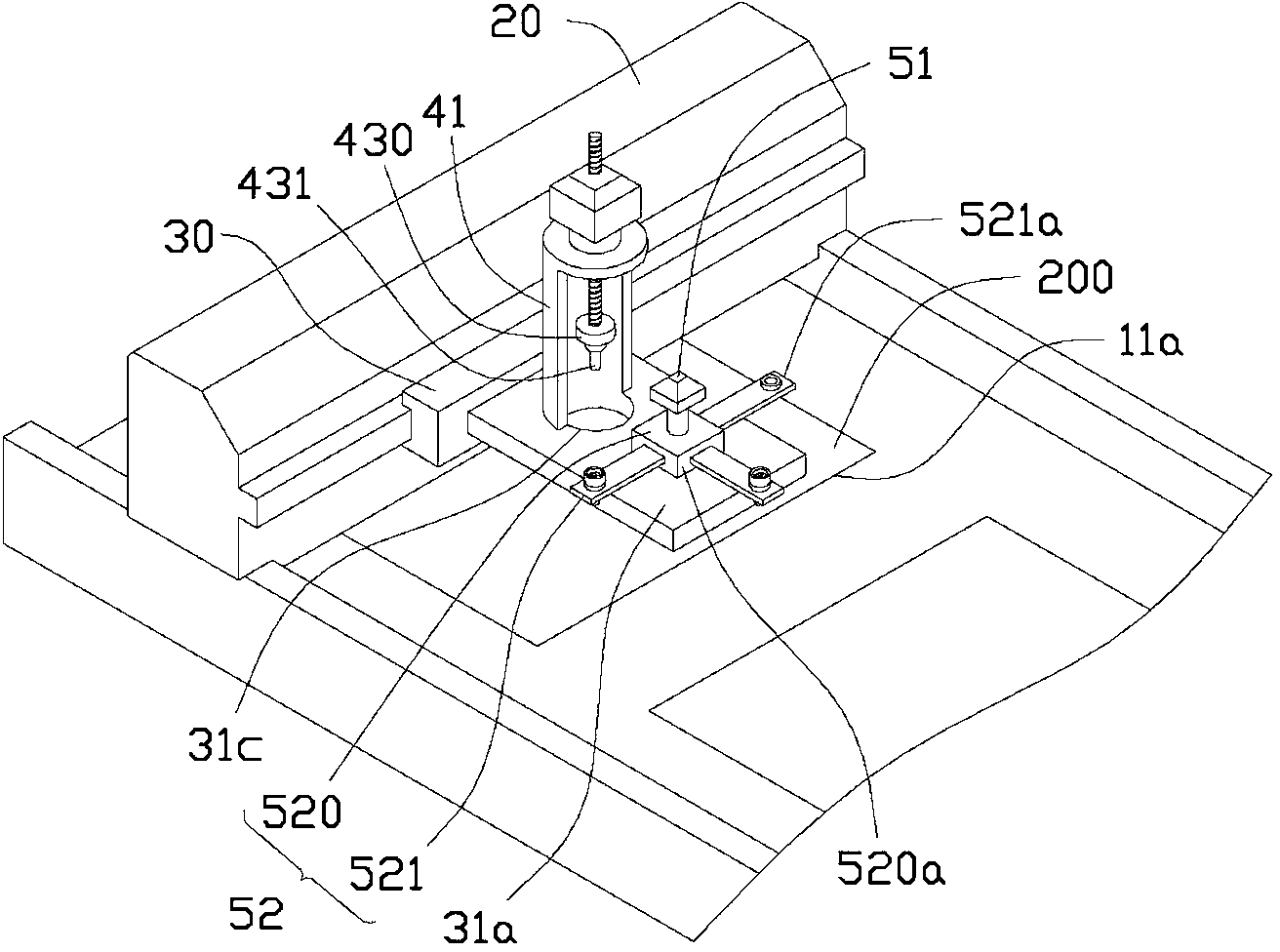

[0013] see figure 1 , the lens cutting device 100 provided by the present invention. The lens cutting device 100 includes a carrying platform 10 , a first sliding assembly 20 , a second sliding assembly 30 , a cutting assembly 40 and a knife replacement assembly 50 .

[0014] The carrying platform 10 includes a carrying surface 11 and a first sliding portion 12 fixed on the carrying surface 11 . The carrying platform 10 is a rectangular structure. The carrying surface 11 is processed with a plurality of rectangular substrate receiving grooves 11 a along its length direction. The substrate receiving groove 11 a is used to accommodate the glass substrate 200 . The first sliding portion 12 is two sliding rails extending parallel along the length direction of the carrier platform 10 and located on both sides of the plurality of substrate receiving grooves 11a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com