Production method of ultrahigh count pure cashmere spun yarns

A production method and ultra-high-count technology, applied in the field of pure cashmere worsted ultra-high-count yarn, can solve the problem of uneven quality of worsted pure cashmere spinning high-count yarn products, increase the quality of worsted high-count pure cashmere Yarn raw material cost, control is not very ideal and other problems, to achieve the effect of reducing cashmere fiber damage, improving lubricating performance, and increasing production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

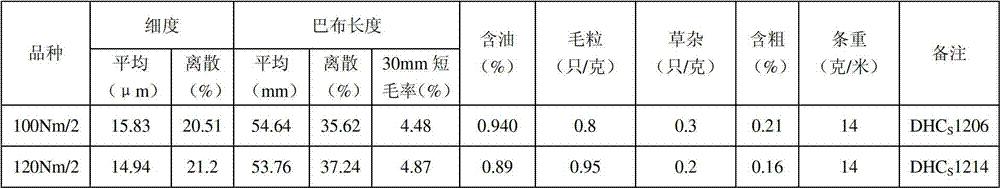

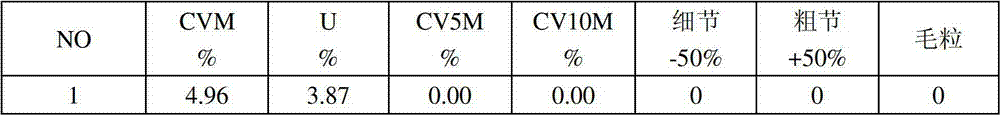

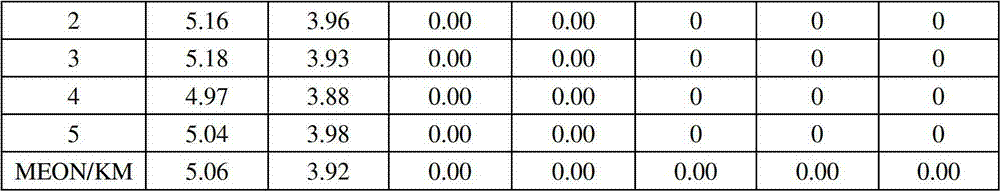

[0046] A method for producing ultra-high-count pure cashmere worsted yarn, characterized in that: the production method comprises the following steps:

[0047] 1) Raw material opening: domestic FB101 opening machine is used, the raw materials should be loosened before being put on the carding machine, and the cashmere fiber cluster should be further loosened, and after being put on the carding machine, it should be fully mixed, and the cashmere raw materials of different qualities should be fully and evenly distributed , as much as possible to remove the grass and defects in the cashmere, to further separate the fiber bundles into single fiber state, and to reduce the damage of the fibers as much as possible, so the distance and speed ratio of the carding machine should be reasonably selected, and the main fiber should be reduced. Cylinder speed, low-load feeding, quantitative delivery;

[0048] 2) Carding: Italian carding machine, namely N.COSMATEX;

[0049] 3) Comb 1: use G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com