An empty box vertical wall combined honeycomb storage silo

A honeycomb-shaped, combined technology, applied in the field of silo structure, can solve the problems of increasing land area, wasting space, uneconomical, etc., and achieve the effect of reducing the occupied area, avoiding excessive bending moment, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

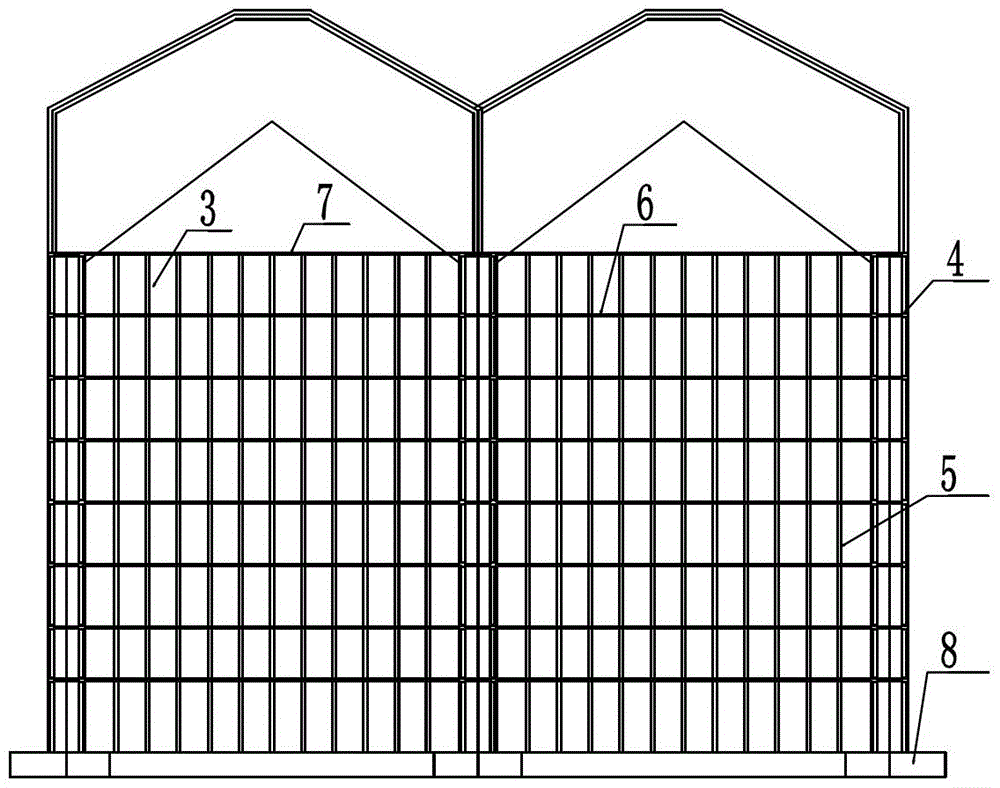

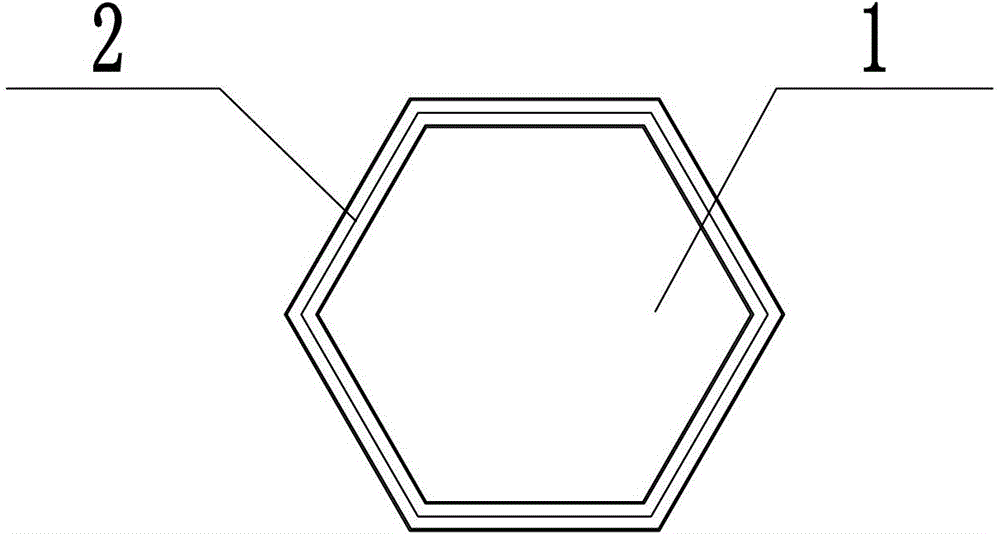

[0024] Embodiment 1 of the present invention: as figure 1 with figure 2 As shown, a fasting box vertical wall combined honeycomb storage warehouse is composed of two honeycomb units 1, and the honeycomb unit 1 includes six equilateral fasting box-type vertical walls 2, and the two sides of the fasting box-type vertical wall 2 are provided with There is a wallboard 3, the top of the wallboard 3 is provided with a cover plate 7 and the bottom of the wallboard 3 is connected with the warehouse body foundation 8.

[0025] The honeycomb cells 1 are combined vertically.

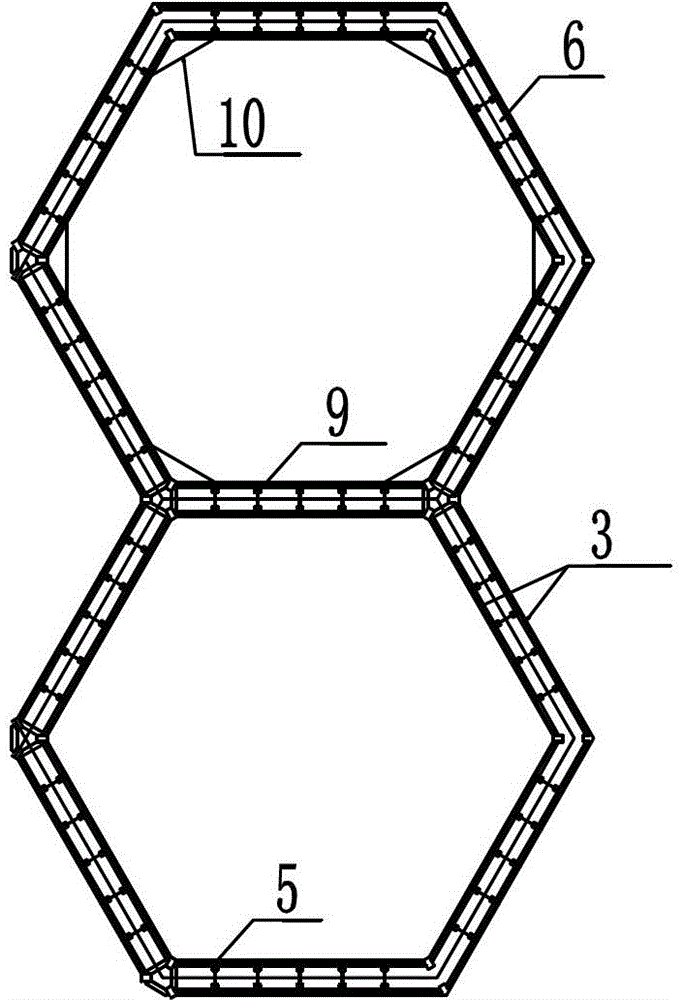

[0026] Such as image 3 As shown, a common side wall 9 is provided between two adjacent honeycomb units 1 .

[0027] For the fasting box-type vertical wall 2, hollow walls of equal thickness can be used in the vertical direction; the horizontal section corners of the fasting box-type vertical wall 2 are provided with ribs and haunch plates 10; the outside of the fasting box-type vertical wall 2 is provided with...

Embodiment 2

[0030] Embodiment 2 of the present invention: as figure 1 with figure 2 As shown, a fasting box vertical wall combined honeycomb storage warehouse is composed of four honeycomb units 1, and the honeycomb unit 1 includes six equilateral fasting box-type vertical walls 2, and the two sides of the fasting box-type vertical wall 2 are provided with There is a wallboard 3, the top of the wallboard 3 is provided with a cover plate 7 and the bottom of the wallboard 3 is connected with the warehouse body foundation 8.

[0031] The honeycomb units 1 are combined in the lateral direction.

[0032] Such as Figure 4 As shown, there are 51 side walls 9 shared between 4 adjacent honeycomb units 1 .

[0033] The fasting box-type vertical wall 2 can adopt a hollow wall with variable thickness in the vertical direction; the horizontal section corner of the fasting box-type vertical wall 2 is provided with ribs and axillary plates 10; the inner side of the fasting box-type vertical wall 2 ...

Embodiment 3

[0036] Embodiment 3 of the present invention: as figure 1 with figure 2 As shown, a fasting box vertical wall combined honeycomb storage warehouse is composed of four honeycomb units 1, and the honeycomb unit 1 includes six equilateral fasting box-type vertical walls 2, and the two sides of the fasting box-type vertical wall 2 are provided with There is a wallboard 3, the top of the wallboard 3 is provided with a cover plate 7 and the bottom of the wallboard 3 is connected with the warehouse body foundation 8.

[0037] The honeycomb units 1 are combined in the lateral direction.

[0038] Such as Figure 4 As shown, there are 51 side walls 9 shared between 4 adjacent honeycomb units 1 .

[0039] The fasting box-type vertical wall 2 can adopt a hollow wall with variable thickness in the vertical direction; the horizontal section corner of the fasting box-type vertical wall 2 is provided with ribs and axillary plates 10; the outer side of the fasting box-type vertical wall 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com