Valve timing changing device

A timing change device and gas distribution technology, which is applied to valve devices, non-mechanically actuated valves, output power, etc., can solve the problem of unlocking the locking mechanism or locking cannot work normally, increased processing costs, complex structures, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

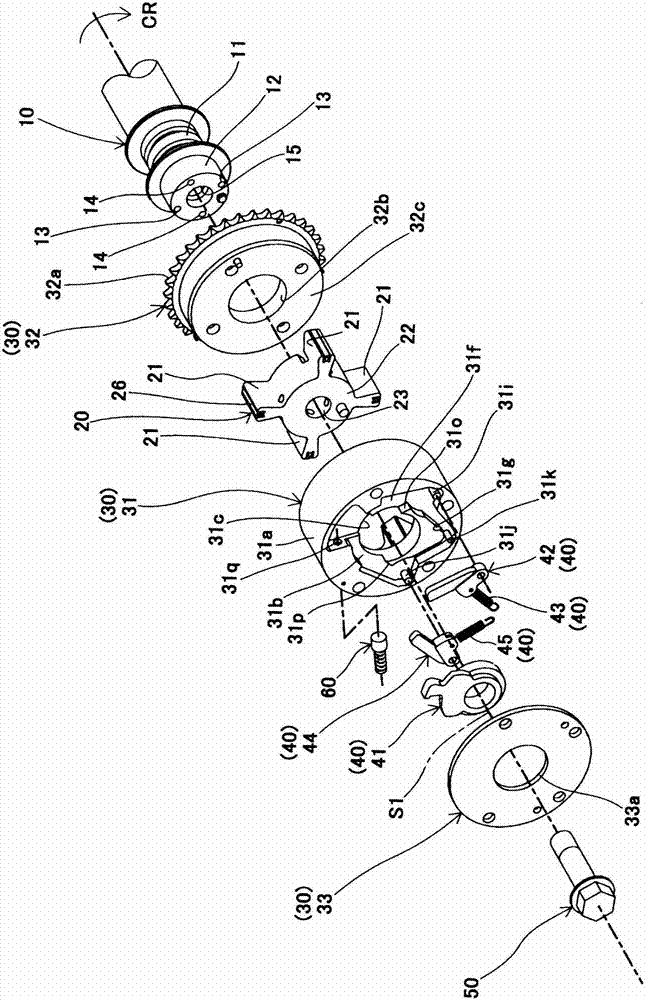

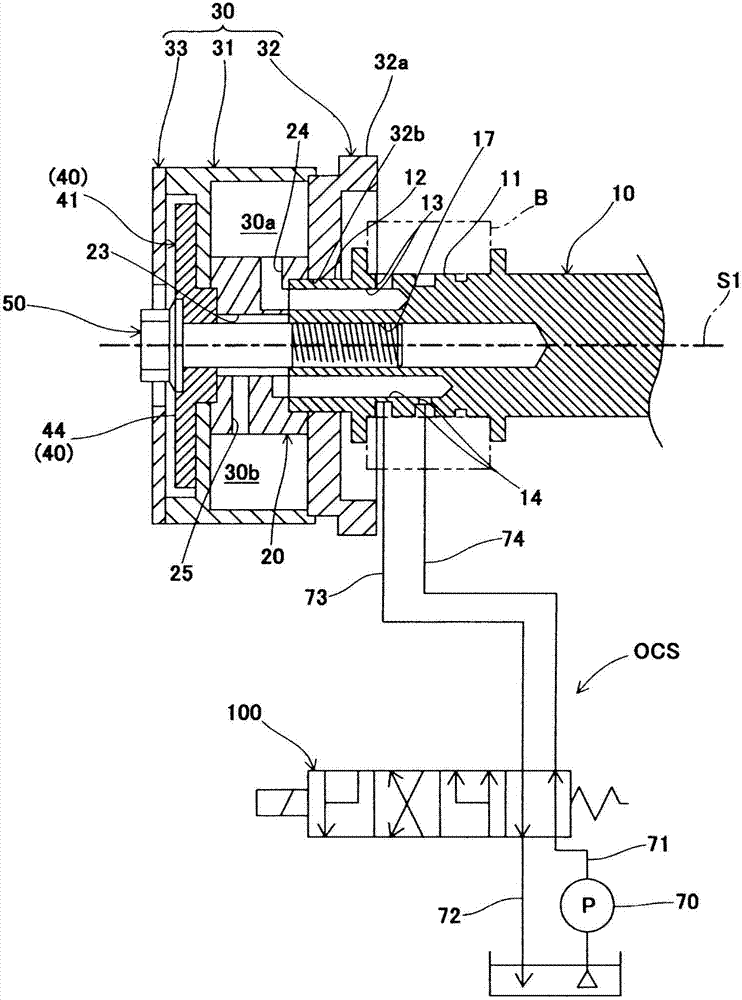

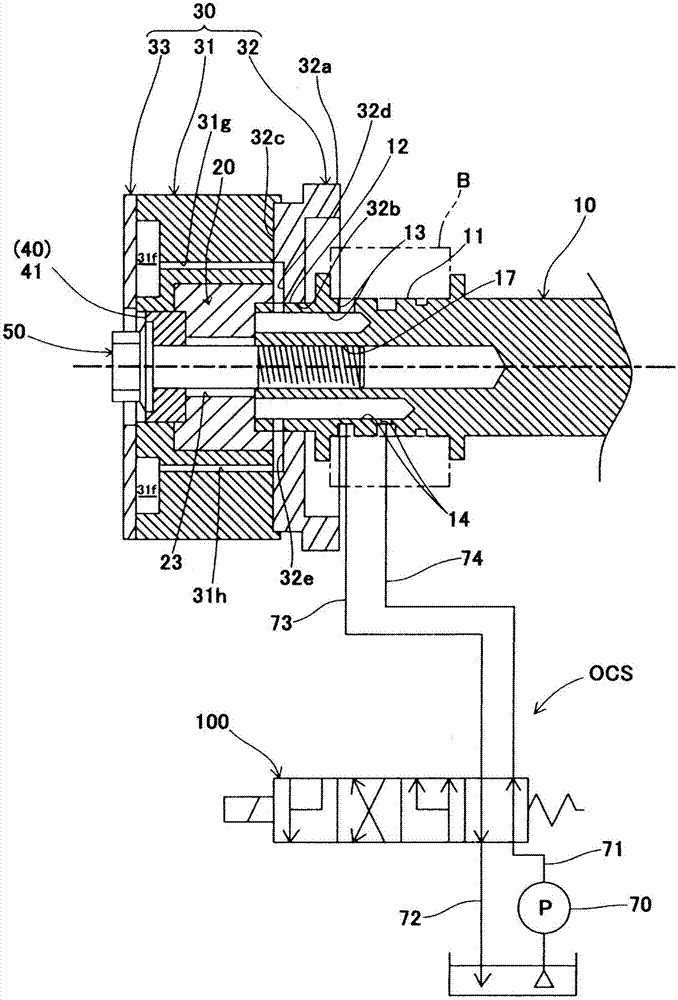

[0117] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0118] Such as Figure 1 to Figure 3 As shown, the valve timing changing device includes the following components: the vane rotor 20 is detachably fixed to the camshaft 10; the housing rotor 30 rotates on the axis S1 of the camshaft 10 and The vane rotor 20 is accommodated to be able to rotate relatively, and the casing rotor 30 and the vane rotor 20 together define an advance angle chamber 30a and a lag angle chamber 30b; the locking mechanism 40 (locking cam 41, advance angle lock lever 42, advance angle Limiting spring 43, lagging angle locking lever 44, lagging angle limiting spring 45), which are arranged in the isolation chamber of the housing rotor 30, so as to lock the vane rotor 20 at a predetermined intermediate position relative to the housing rotor 30; the central bolt 50, It fastens the vane rotor 20 to the camshaft 10; the auxiliary mechanism 60 assists i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com