Pump with replaceable assembled liner

A technology of lining and pump body, applied in the direction of pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve the problem of high design cost and production cost, waste of manpower, material and financial resources, and unfavorable standardized manufacturing sites. Changes in the working conditions of the device, etc., to achieve the effects of small vibration, improved utilization, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

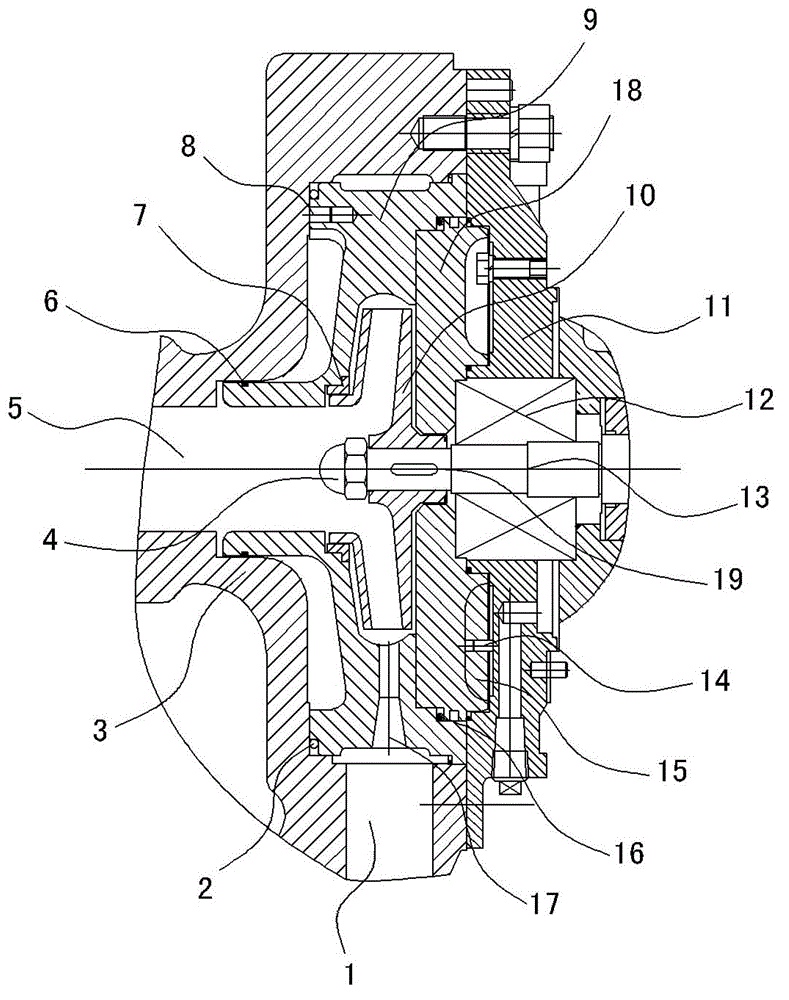

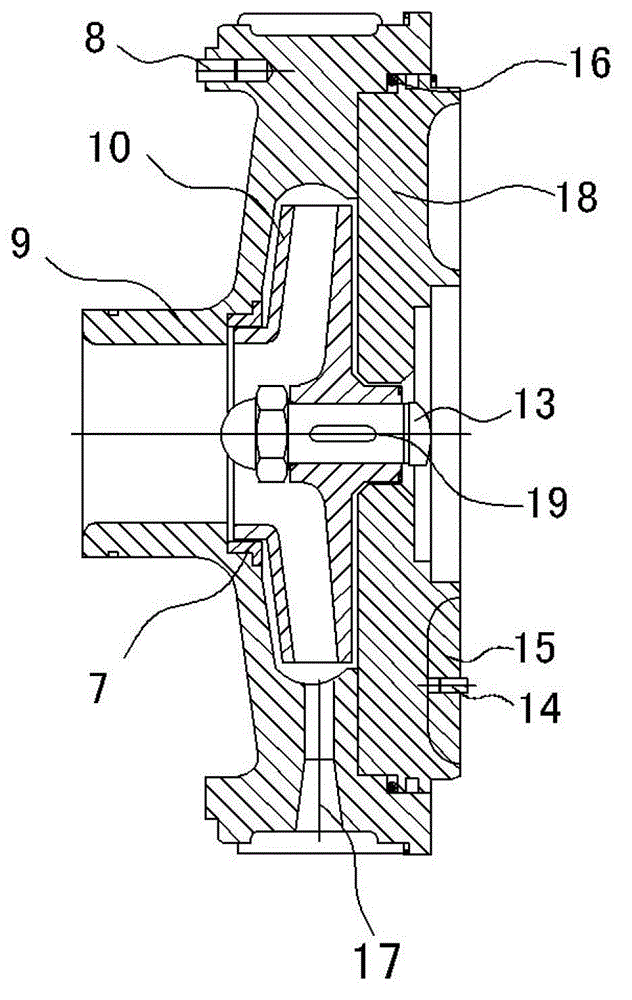

[0021] see figure 1 with figure 2 , the structural form of the pump with replaceable combined liner in this embodiment is: a replaceable combined liner is set in the pump chamber formed by the pump body 3 and the seal chamber cover 11; the combined liner includes an impeller 10, a volute core 9 and volute core cover 18;

[0022] Such as figure 1 with figure 2 Shown:

[0023] The impeller 10 is fixed on the pump shaft 13 through the key 19, and is tightened by the impeller nut 4. The impeller nut 4, the impeller 10 and the pump shaft 13 rotate together, and the impeller nut 4 prevents the impeller 10 from turning loose or falling off from the pump shaft 13;

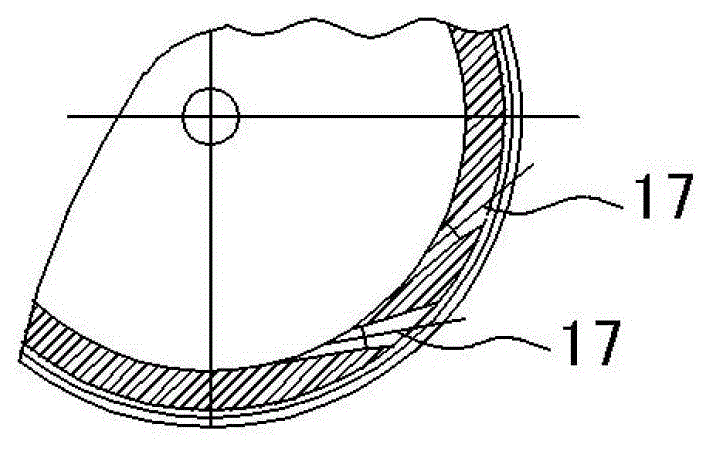

[0024] The volute core 9 is located between the pump body 3 and the sealing chamber cover 11, one end of the volute core 9 is positioned on the pump body 3 through the volute core positioning pin 8, and the other end is closed by the sealing chamber cover 11, and the volute core 9 is The fixed position formed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com