Water distribution method of superlarge refluxing type natural ventilation cooling tower

A natural ventilation and cooling tower technology, applied in the direction of water shower coolers, heat exchanger types, direct contact heat exchangers, etc., can solve problems such as distortion of water distribution calculation results, complex errors in water distribution systems, and poor water distribution uniformity of cooling towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate understanding of the present invention, the following will be described in conjunction with the accompanying drawings.

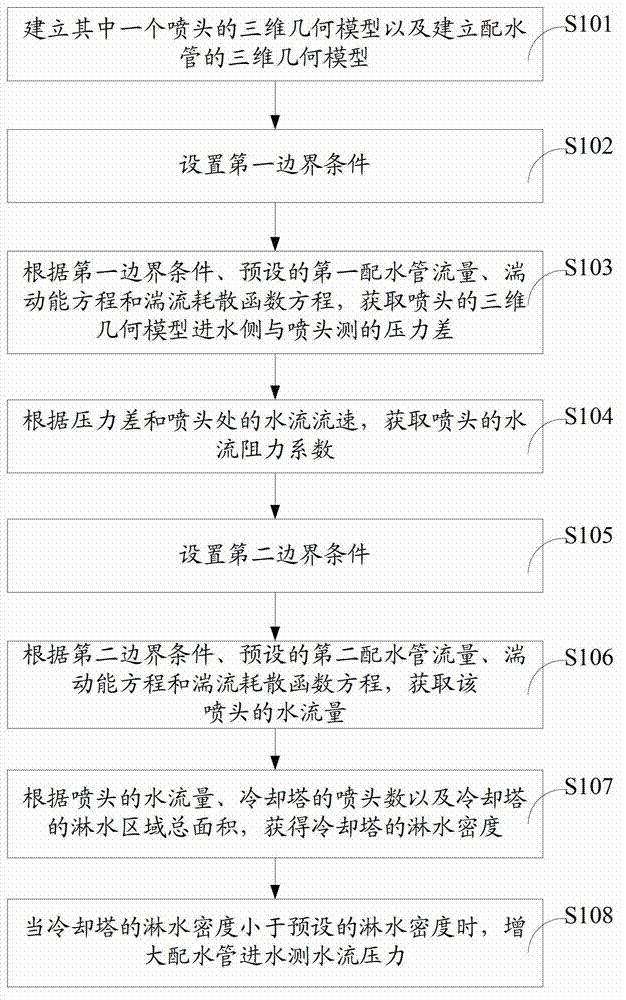

[0021] The present invention proposes a method for distributing water to a super-large counterflow natural draft cooling tower, please refer to figure 1 , including the steps:

[0022] S101, establishing a three-dimensional geometric model of one of the nozzles and establishing a three-dimensional geometric model of the water distribution pipe;

[0023] S102, setting a first boundary condition;

[0024] Set the first boundary condition; wherein, the first boundary condition includes: the water flow pressure and water flow velocity of the water inlet side section of the water distribution pipe, the water flow pressure and water flow velocity of the nozzle, and the water flow pressure and water flow velocity of the inner wall surface of the water distribution pipe.

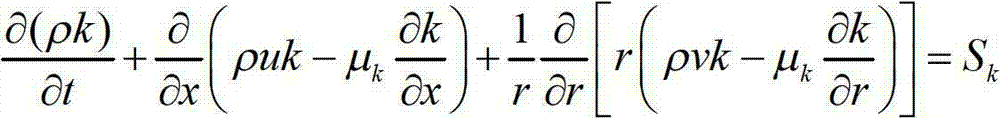

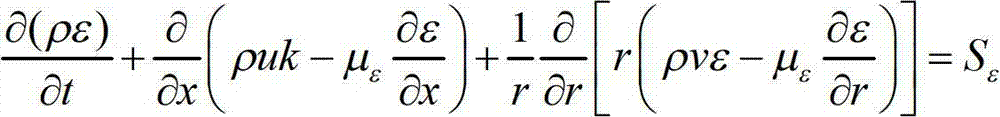

[0025] S103. According to the first boundary condition, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com