Pickled pepper flavor konjak leisure food and production process of food

A technology of snack food and production process, applied in food preparation, food science, application and other directions, to achieve the effect of strong antioxidant, strong chewiness and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation process is as follows: pre-cooking konjac products in water at 95°C for 20 minutes, pre-cooking can remove the alkali contained in the products; rinsing the pre-cooked konjac products with clean water until they are cleared. , and then drained; the drained konjac products were processed in pickled pepper water for 12 hours, then filtered, and then added monosodium glutamate, chicken essence, nucleotides, white sugar, ethyl maltol, sodium iso-VC and dehydroacetic acid in proportion Sodium, then stirred and mixed; bagged, sealed and sterilized.

[0031] Pickled pepper water is made from the following raw materials in parts by weight: 600 parts of purified water, 40 parts of pickled pepper, 12 parts of ginger, 6 parts of garlic, 1.2 parts of green pepper, 3 parts of edible lactic acid, 0.5 part of edible acetic acid, and 0.8 part of chili oleoresin , 35 parts of salt. As a preference, the pickled peppers are made of hot millet, and the ginger is preferably...

Embodiment 2

[0035] The preparation process is as follows: pre-cooking konjac products in water at 95°C for 20 minutes, pre-cooking can remove the alkali contained in the products; rinsing the pre-cooked konjac products with clean water until they are cleared. , and then drained; the drained konjac products were processed in pickled pepper water for 12 hours, then filtered, and then added in proportion to monosodium glutamate, chicken essence, nucleotides, white sugar, chicken paste, ethyl maltol, sodium iso-VC and Sodium dehydroacetate, then stir and mix; carry out bagging, sealing and sterilization.

[0036] Pickled pepper water is made from the following raw materials in parts by weight: 600 parts of purified water, 40 parts of pickled pepper, 12 parts of ginger, 6 parts of garlic, 1.2 parts of green pepper, 3 parts of edible lactic acid, 0.5 part of edible acetic acid, and 0.8 part of chili oleoresin , 35 parts of salt. As a preference, the pickled peppers are made of hot millet, and ...

Embodiment 3- Embodiment 6

[0040]

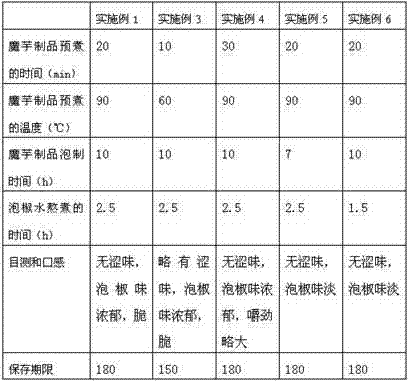

[0041] As can be seen from the table, embodiment 1 is compared with embodiment 2, and it can be seen that the time of pre-cooking and the temperature of pre-cooking have a greater impact on the mouthfeel, and the pre-cooking time is shorter, and the astringent taste in konjac products cannot be completely removed , will feel slightly astringent when eating, so need to control the temperature and the time of precooking, compare embodiment 1 with embodiment 5, the time that konjac products are soaked in pickled pepper water and will affect the soaking time of konjac products. The entry of pepper flavor also has a certain impact on the mouthfeel. Comparing Example 1 with Example 3, changing the precooking time will change the color of konjac products before seasoning and affect the sensory perception. Embodiment 1 is compared with embodiment 6, illustrates that the boiling time of changing pickled pepper water can affect the pickled pepper taste in the konjac snack foo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com