Heat preservation electric heating thermos

A thermos bottle, water bottle technology, applied in the direction of boiling water utensils, cooking utensils, household utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

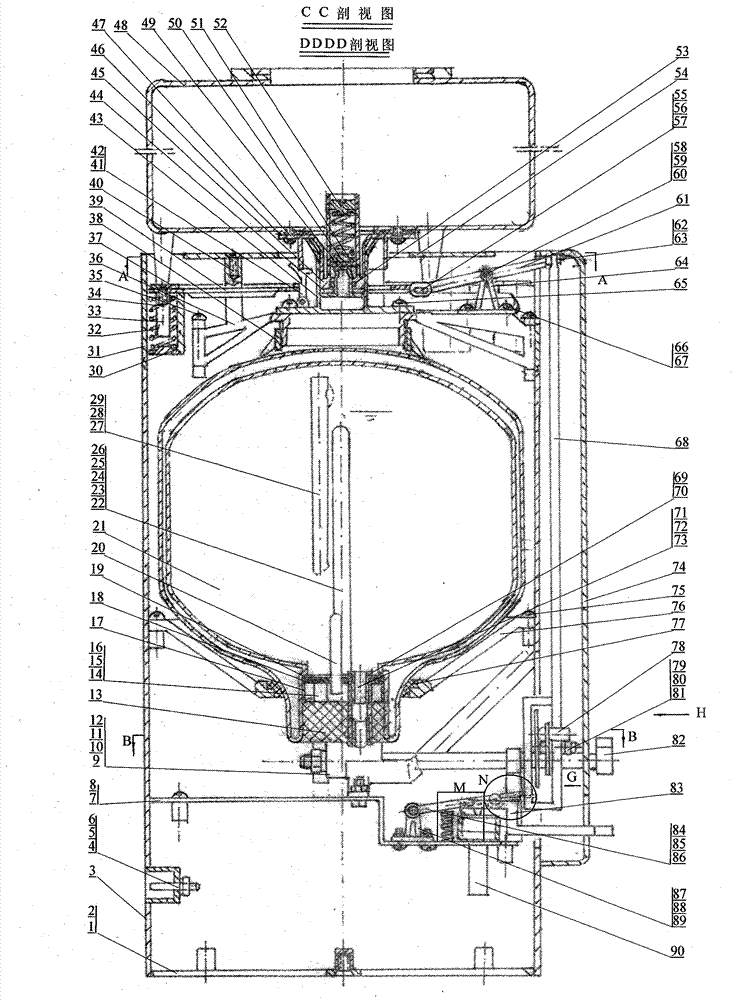

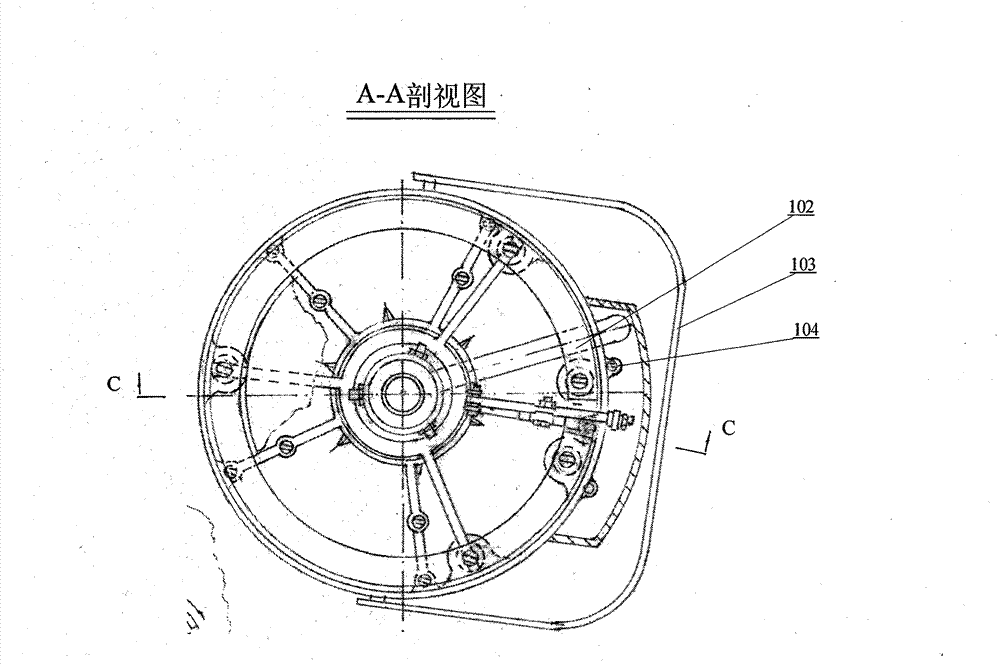

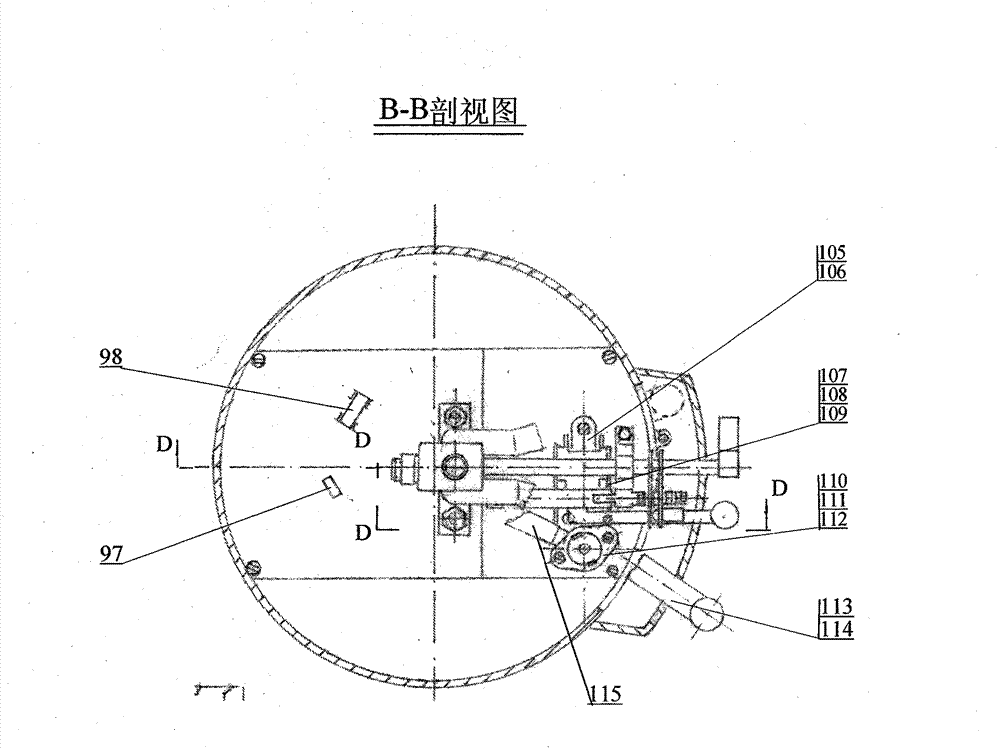

[0018]More than 120 parts of the present invention can be produced by conventional methods, wherein there are 34 standard parts small screws, small nuts, small spacers, and split ends, 10 rubber pads, and 4 small springs. The bottle liner, bottle shell and three-way valve are large parts, while others are small parts. The production process of bottle liner is described below. For glass liners, borosilicate glass and soda lime silicate glass can be used. The process flow is: Melting→blowing (rotary blowing method)→annealing→cutting→tempering treatment→welding of inner and outer liner sleeves→outer liner welding of bottle bottom or grabbing the bottom of the bottle→opening welded pipe→metal plating→vacuumizing→ Seal tube. The production process of the inner and outer tanks is the same, except that the outer tank has no bottom, and the bottom of the bottle needs to be blown and then welded to the upper cylinder or directly grasped by the upper cylinder. If it is made of borosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com