Drawing die used for manufacturing axial lock housing

A technology for stretching molds and lock covers, which is applied in the direction of manufacturing tools, forming tools, metal processing equipment, etc., and can solve problems such as low yield and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

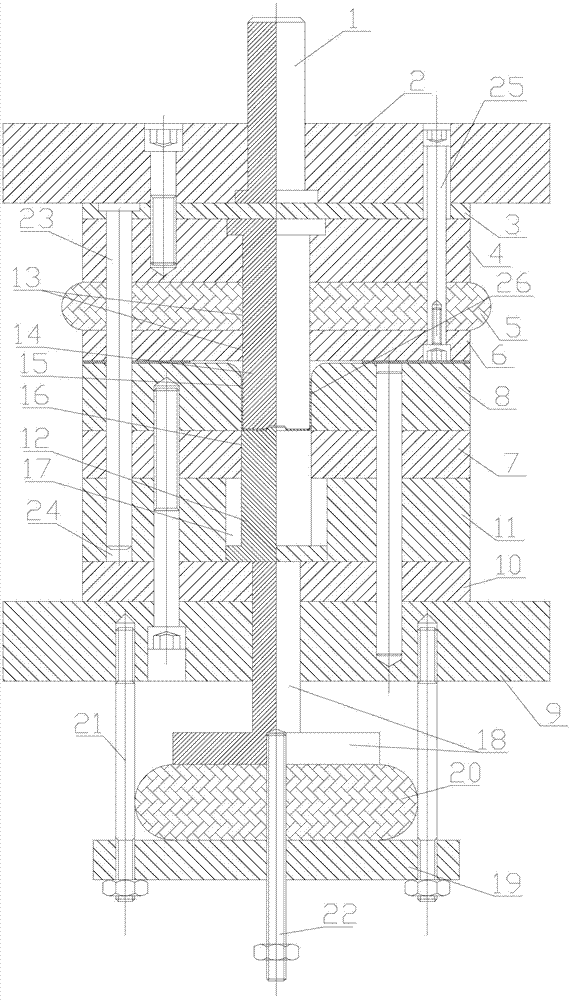

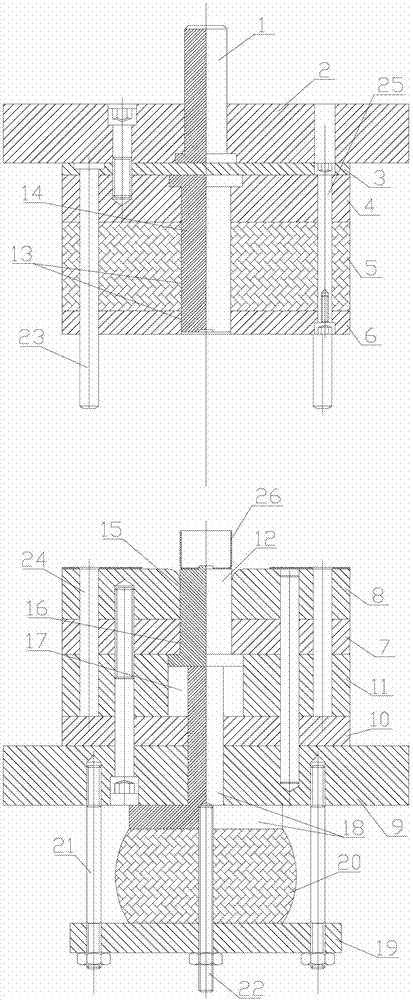

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] The present invention is used for the stretching die of manufacturing axial lock case, and it comprises die handle 1, upper template 2, upper die backing plate 3, is provided with the upper fixed plate 4 of punch 14, first elastic body 5, stripping material Plate 6, lower template 9, lower mold backing plate 10, lower fixed plate 11, movable mold cover 7, lower mold 8, movable mold 12, said upper template 2, upper mold backing plate 3, upper fixed plate 4, first The elastic body 5 and the stripping plate 6 are sequentially connected from top to bottom, and the lower template 9, lower mold backing plate 10, lower fixed plate 11, movable mold cover 7, and lower mold 8 are sequentially connected from bottom to top, so The punch 14 is fitted with the first elastic body 5 and the first hole 13 provided in the stripper plate 6 for the punch 14 to pass through so that the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com