Clamping positioning device

A technology of clamping positioning and fixing blocks, which is applied in the field of mechanical processing, can solve the problems of reducing product qualification rate, affecting product quality, affecting clamping accuracy, etc., and achieves the effect of solving upturning, safe and reliable use, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

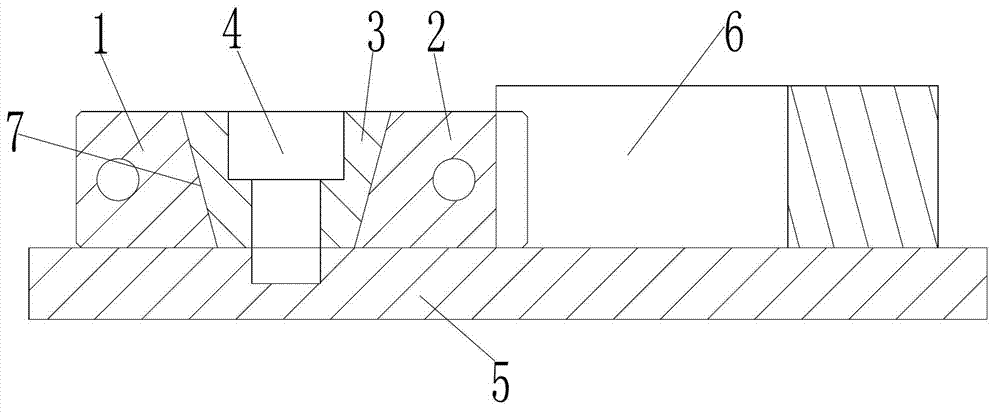

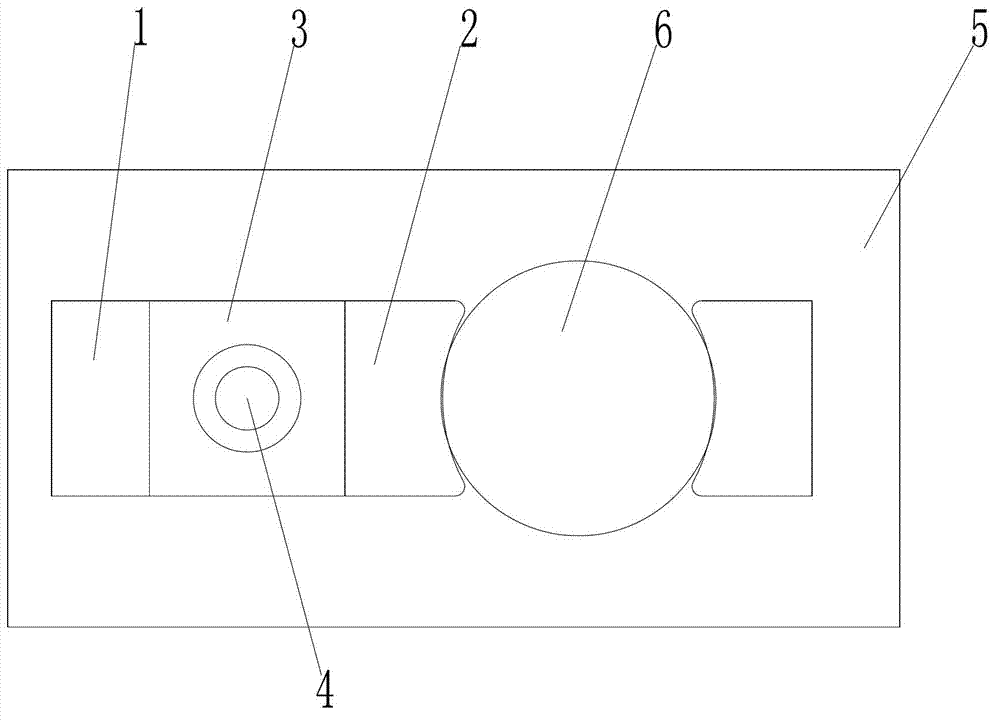

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] attached figure 1 , 2 It is a clamping and positioning device according to the present invention. The clamping and positioning device is used to clamp and position the workpiece 6 on the worktable panel 5, and mainly includes a fixed block 1, a pressing block 2 and a sliding block 3, and the fixed block 1 is fixedly installed on the workbench panel 5, and the sliding block 3 is movably installed on the workbench panel 5. The sliding block 3 is a wedge block on the upper side and the lower side, and is connected between the fixed block 1 and the pressing block 2. The fixed block 1 The connecting surfaces of the sliding block 3, the pressing block 2 and the sliding block 3 are the slope surface 7 matching the shape of the sliding block 3, and the sliding block 3 is locked downward by the locking screw 4 to push the pressing block 2 to achieve the workpiece 6 clamping.

[0014] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com