Paper leveling device

A leveling device and paper technology, applied in the direction of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of reducing economic benefits, bending or warping on both sides of the paper, increasing production costs, etc., to avoid warping or warping Bend down, improve product qualification rate, and facilitate installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

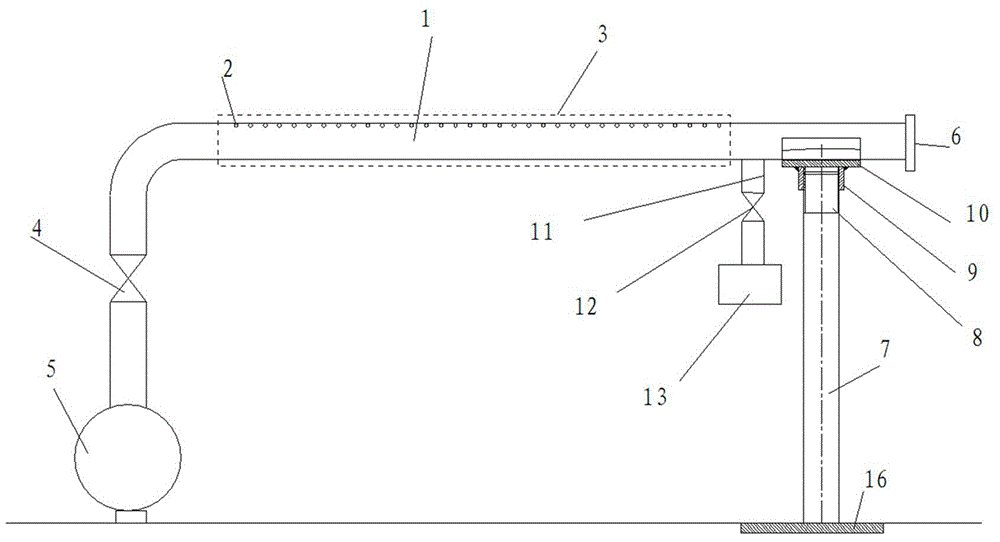

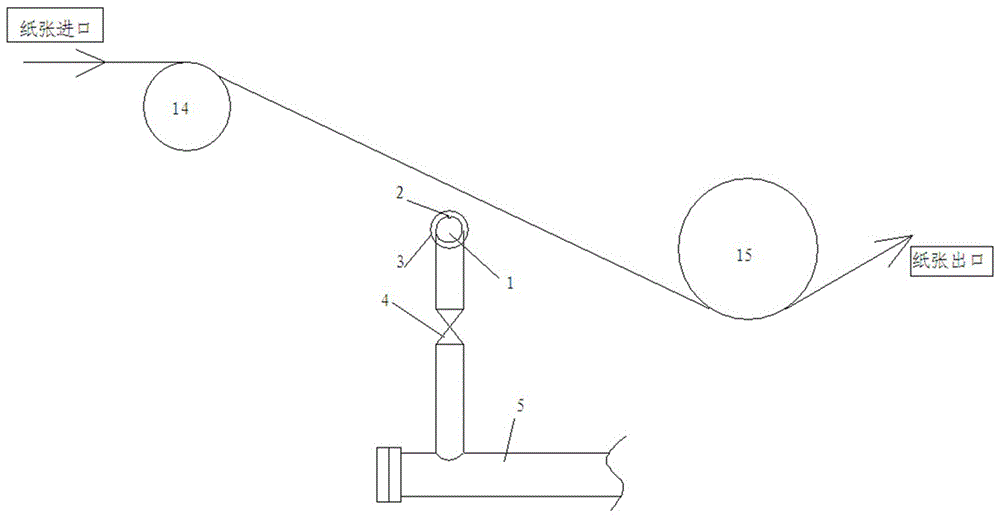

[0016] Such as figure 1 , figure 2 As shown, a paper leveling device includes an air outlet pipe 1 and a bracket. The air outlet pipe 1 is located at the rear side of the adjustment cylinder. The axis of the air outlet pipe is connected to the paper leveling roller, that is, the first roller 14. The axis of the second roller 15 is parallel, the inlet end of the outlet pipe 1 is connected with the steam main pipe 5 of the workshop through the steam regulating valve 4, the end of the outlet pipe 1 is provided with a plug 6, the outlet pipe The upper part of 1 is provided with a number of air outlet holes 2, and a water outlet is provided on the air outlet pipe near one end of the plug, and the water outlet is connected with the water outlet pipe 11, and the water outlet pipe 11 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com