Threaded fastener and workpiece used for MIG brazing and flame brazing

A technology for flame brazing and threaded fasteners, which is applied in the field of threaded fasteners and workpieces, threaded fasteners and workpieces, can solve the problems of high cost and complicated manufacturing process of riveting nuts, and achieve low welding pressure, Good welding quality and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 14

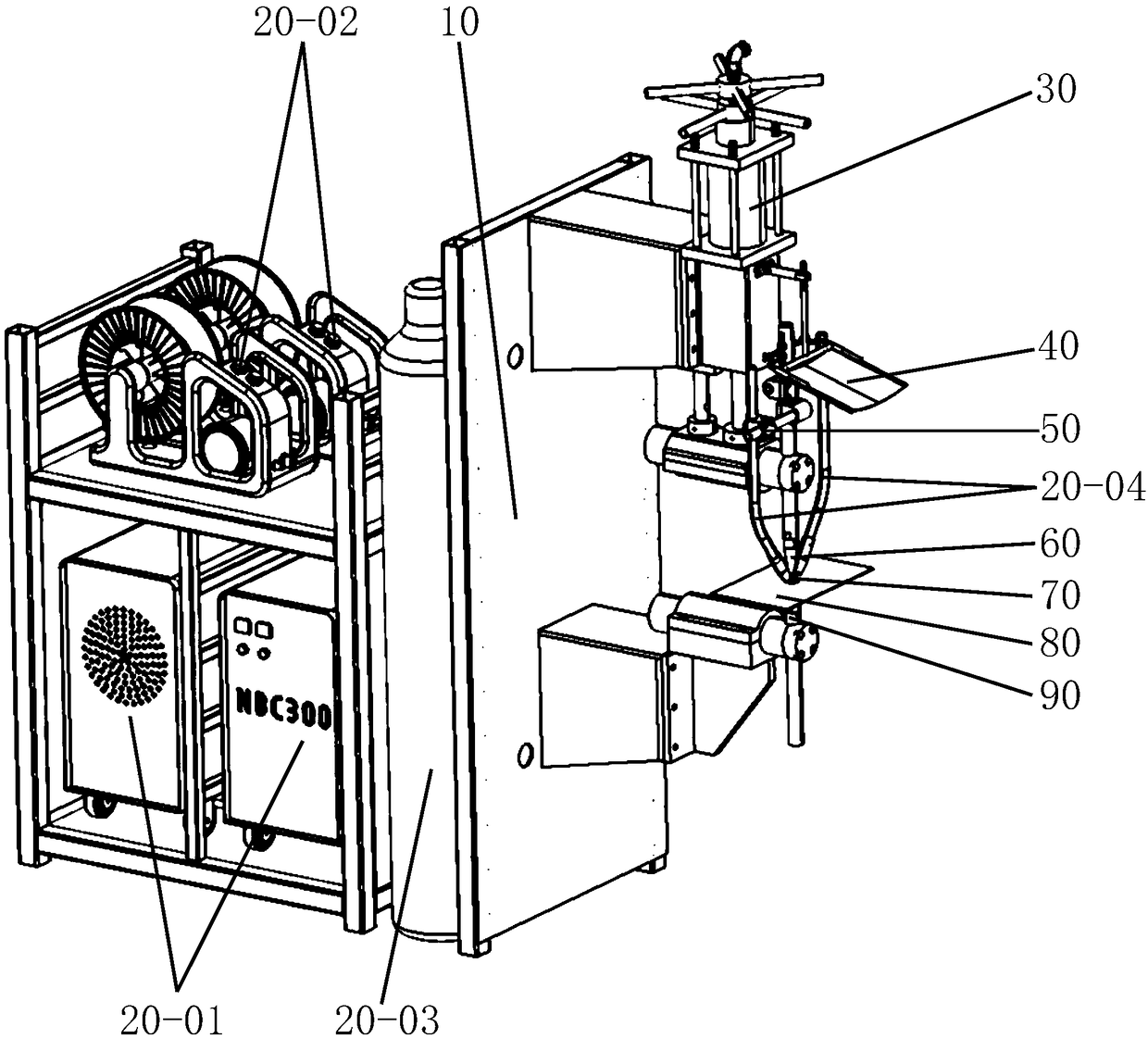

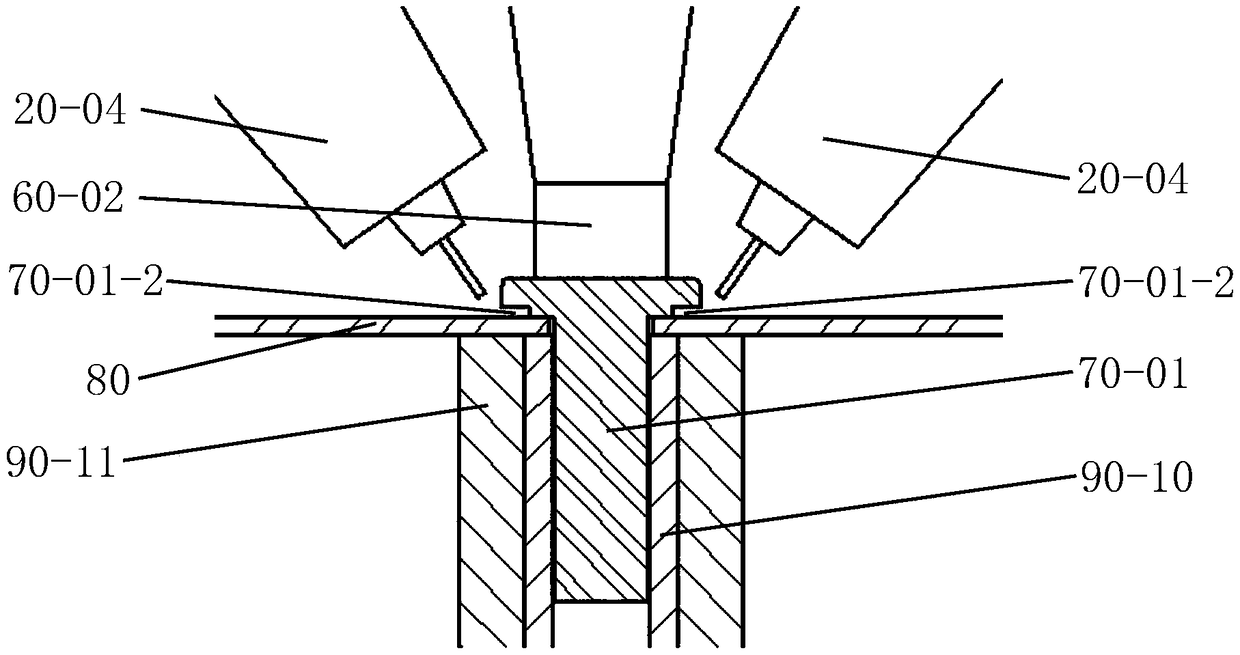

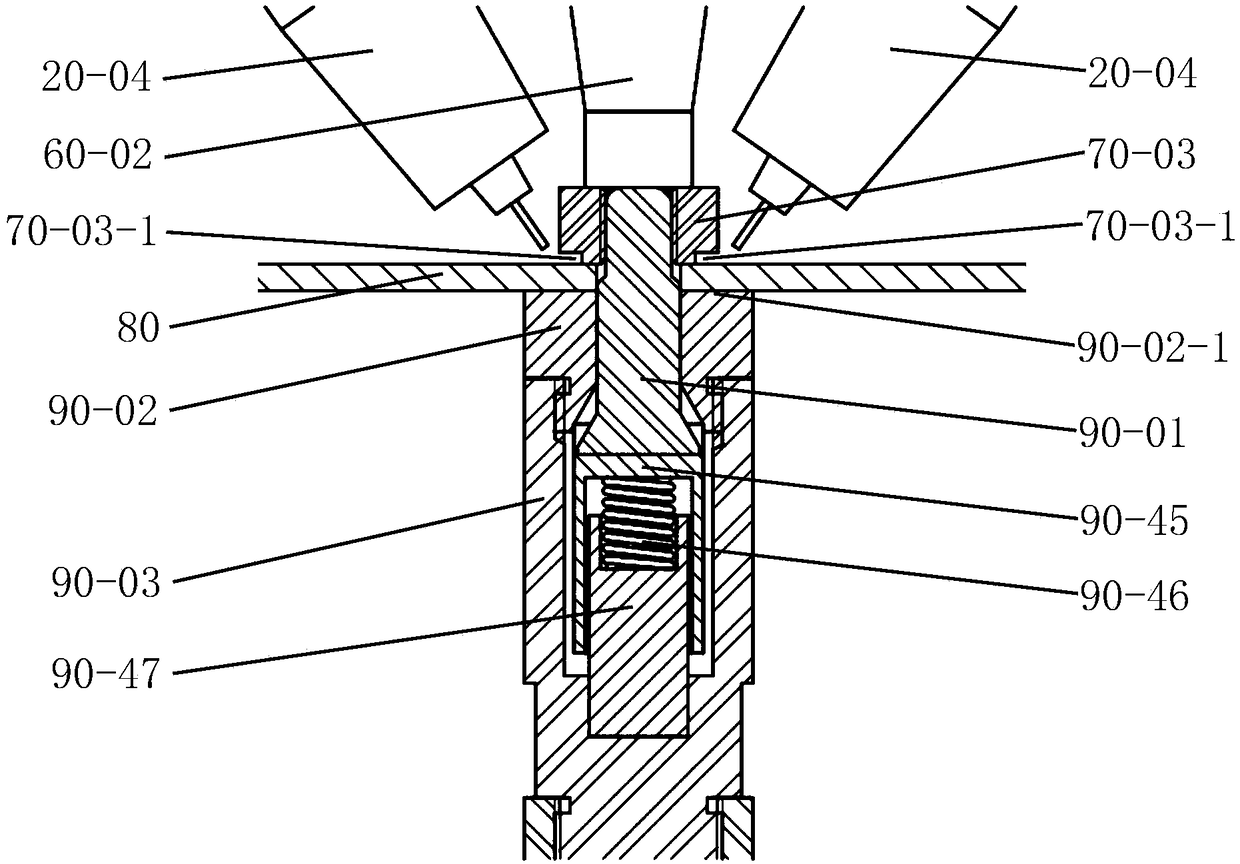

[0025] Embodiment 14: This embodiment is a technical solution designed for brazing, especially MIG brazing and flame brazing. Before welding, the welding part of the threaded fastener is processed into a solder groove, and then welding is performed, as figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 . The height of the solder groove is between 0.1-3mm, and the depth is between 2-20mm. Brazing is achieved by capillary or infiltration of molten solder on objects (threaded fasteners and workpieces). It is necessary to press the threaded fastener and the workpiece tightly, so the gap at the joint will be small, and the resistance of the liquid solder to enter is very large. However, it often takes a certain amount of time to realize that the brazing filler metal has sufficiently infiltrated the bonding surface of the threaded fastener and the workpiece. Because the solder is melted on the outside, enough temperature and time are needed to infiltrate it, but the distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com